Vacuum metallized film

Vacuum

The main division for aluminum vacuum metallized films is as below

- VMPET film (PET film substrate)

- VMCPP film (CPP film substrate)

- VMPA film (PA film substrate)

- VMBOPP film (BOPP film substrate)

- VMPE film (PE film substrate)

- Metallized Paper (Paper substrate)

Change after vacuum metallized

Let’s have a look on the change of appearance before and after vacuum metallized.

After metallization, the polymer film will be enabled with

- Bright metallic appearance (for decoration)

- High barrier performance against oxygen and water vapor (for barrier packaging)

- Sunlight shielding (for packaging and thermal insulation)

- Electrical conductivity (For electronic and packaging purpose)

Cost-effective Film

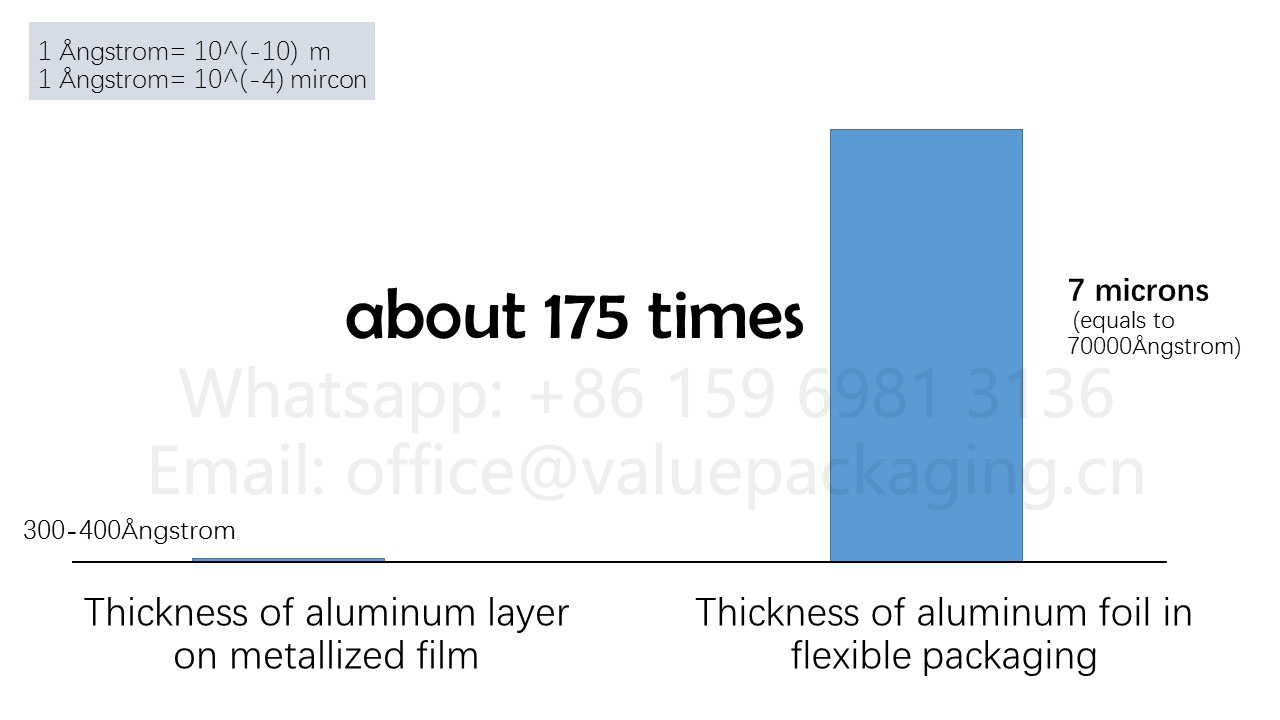

Previously we talk about the thin aluminum layer deposited onto the polymer surface, can you imaging how thin the aluminum layer is? Let’s have a graphic comparison

With this so thin aluminum layer on the polymer film surface, it can achieve the barrier performance that most products will be ok, and as aluminum foil is of

Vacuum Metallization Depositing Craftsmanship

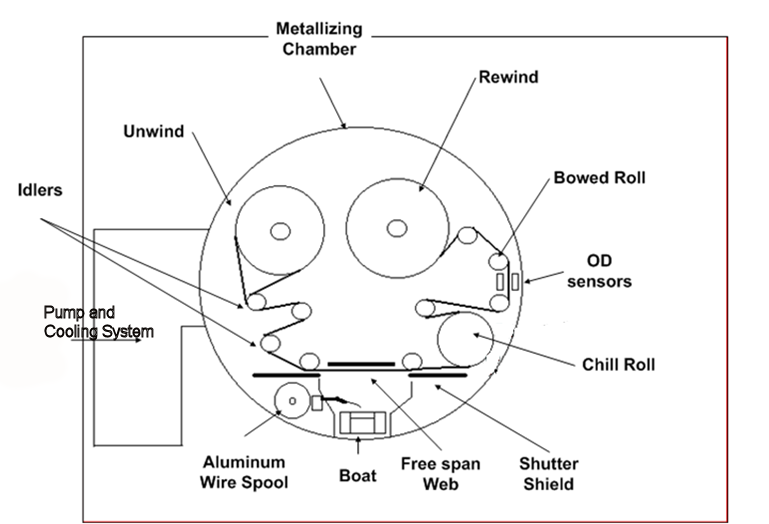

You may have a detailed look into this vacuum metallization depositing schematic if you interest.

and the machine intended to realize the vacuum metallization process is usually called vacuum