A zipper is most widely applied to make a package re-sealable that is essential for products that can not be run out in just one time, like coffee beans, dog foods, dry nuts, snacks, cookies etc. As a reliable manufacturer of standup pouch packages in Qiingdao, china, we are going to give a simple introduce to the zippers applied in flexible packaging areas, so the customer can have a good access to it, and easy choice.

Inner Zipper

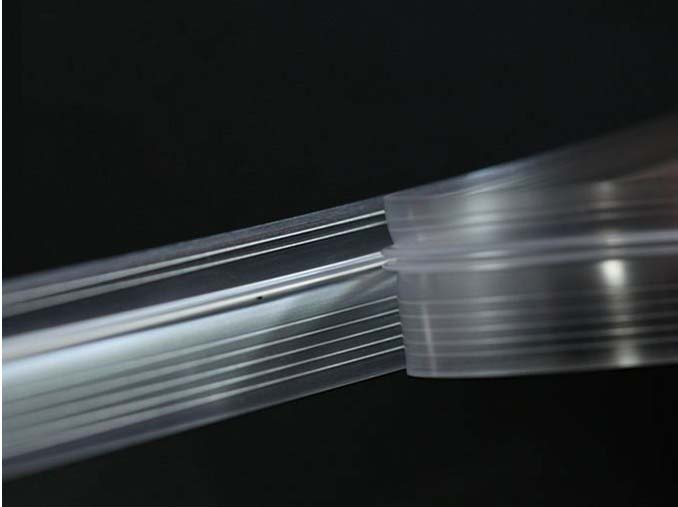

Inner zipper is the most used of all the zippers applied in flexible packaging areas, as it realized reliable re-sealable property for most products at the lowest cost. It consists of two part, the bulged part and the track part. This zipper get its name as it will be trapped inside the two foil laminates of the plastic pouch, with each part heat sealed with each foil laminate. The bulged line will fit into the groove track closely when they are pressed. so the airtight property for the closed zipper comes to important as the package rely on that to keep the products inside in freshness as long as possible.

In order to give you a better way to understand how our zipper pouch perform, we just get the pouch air flushed, and close the zipper, and then heavy pressure applied on the outside of the package, let’s see the how it performs.

Tab Zipper

Tab zipper is also called rip zipper, it gets its name as people will have to pull the tab to open the package. It is developed for easier filling at the manufacturer plant, and easier tear at the end consumers.

As you can obersve from the opening for the inner zipper pouch, as the zipper is fully heated sealed with the foil laminate, so when the zipper pouch is opened, it can only leave a small opening, that will decrease the products filling efficiency. However, the tab zipper is able to provide a large opening for box bottom bag, as you can observe the below picture.

The tab zipper enables much easier use for the end consumers, you can watch the video below for further understanding.

With its obvious advantages, tab zipper are widely used for coffee beans, dog food, pet treats, dry nuts, snacks area etc.

Slide zipper

Slide zipper is developed to realize more easier close and better airtight property for the zipper. As when the slider goes from one side to the other side, it will apply the same pressure on each point of the zipper, so the zipper can be better closed. Watch the video to understand more.

Double track zipper

Zipper can also be applied to the plastic bags that are intended for liquid products. However, single track zipper may face the risk of separation under some pressure, that is not welcome for liquid packages. So double track zipper is developed to realize more safe close to final packages. If liquid products, like milk is packed in the zipper pouch, the milk will not leak out. Watch the video below for more understanding.