In some applications, metallized paper is intended to replace metallized film, as of eco-friendly and cost effective considerations. In order to assist the customers to get the best of what metallized paper is able to offer, we are going to give a further analysis on the structure of metallized paper, hope it is helpful for the customers to get the ideal packages.

Metallized Paper Structure

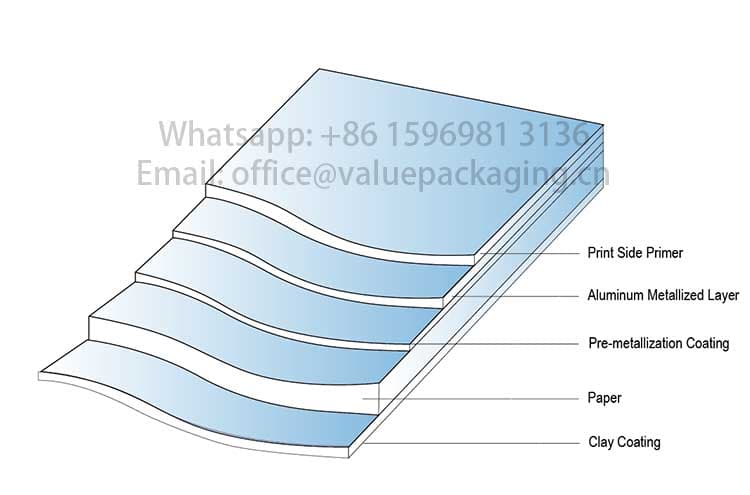

Below graphic shows the detailed structure for metallized paper, with each layer from inner to outer is as below.

- Clay coating

- Raw paper

- Pre-metallization coating

- Aluminum metallized layer

- Print side primer

Raw Paper

Raw paper is usually made from plant fiber, with different lengths of fibers mixed in the paper pulp, so when it is dried into paper substrate, the surface is coarse with dents and humps, that will cause worse presentation for artwork print than a smoothe surface. So to get a smoothe surface with good wetting tension, usually clay coating is applied.

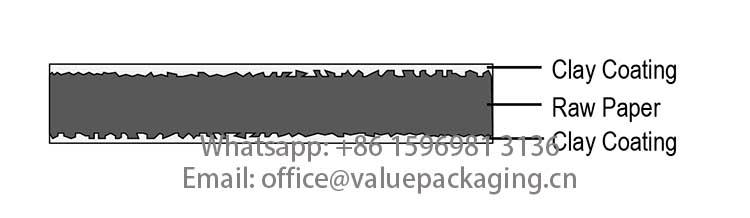

Clay Coating

Clay coating can be applied onto single or both sides of the raw paper, that is usually decided by the end application, as you can check the graphic as below, clay coating is going to achieve a more smoothe surface for further printing and coating operation.

Pre-metallization Coating

Pre-metallization coating layer works like anchor agent that improve the bonding strength between aluminum metallized layer and paper substrate, that is usually achieved before metallization process.

Aluminum Metallized Layer

The thickness of aluminum metallized layer is only 30-50 nanometer, that is only 0.04~0.07% of the paper substrate thickness, so usually the thickness of aluminum metallized layer can be neglected when evaluating the thickness for metallized paper. However, this aluminum metallized layer really plays a big role in the printing and packaging applications.

Print Side Primer

Another layer of top varnish is applied over the aluminum metallized layer, usually working as a protetion layer. As when the metallized paper is intended for print beer labels, usually the print is applied on the surface of aluminum metallized layer, however, aluminum layer would be damaged by the water in the water-type inks. That’s why the varnish layer is needed.

Ok, that’s all I have to say regarding the structure of metallized paper, and I am going to introduce more on the applications of metallized paper. You are welcome to reach us if you have any questions.

Hi, I would like to know the maximum roll width that you can supply? Plan is to print, coat and slit for that paper.

May I also ask for the quotation please?