Description

200grams eco-friendly film materials coffee bag

Watch the video for 200grams ecofriendly kraft paper box bottom coffee bag .

Introduce

This admirable 200grams ecofriendly kraft paper box bottom coffee bag is produced for which presents its preqmium organic roasted coffee beans to the USA market, and this package is well able to present exceptional quality packages for the products, and works as great protection in filling, transport and distrubition process.

Here we are going to give a further analysis on this amazing coffee bag, and hope you will get a fantastic package for your own products.

Renewable Film Materials

This foil materials is a reinforced structure with excellent properties for coffee bag packages. The foil structure is PET12/AL7/PET12/LDPE80, with graphic as below.

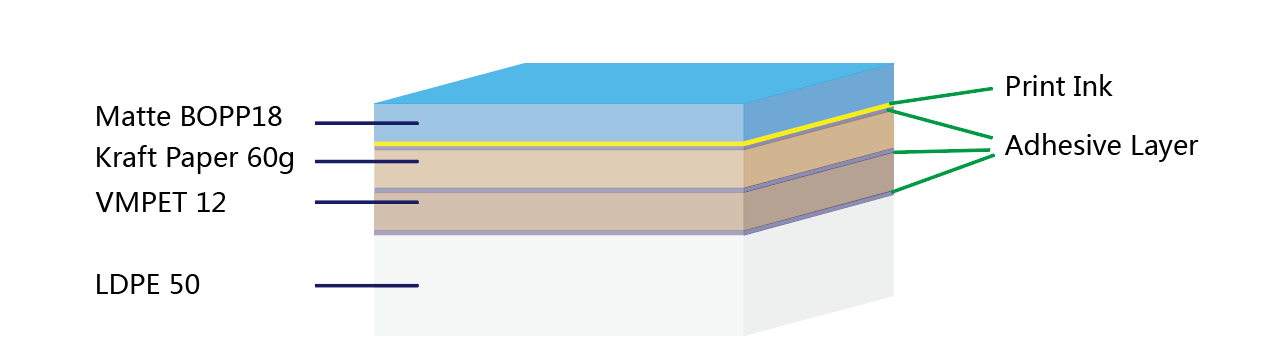

MatteBOPP18-Kraft-paper-60gsm-VMPET12-LDPE-foil-structure

Matte BOPP 18, means biaxially orientated polyproylene film with thickness 18 microsn (equals to 0.72 gauge), in a matte finish appearance. It is specially used when the customer want to print complicated artwork in a vivid effect on kraft paper package. It works on the outside layer, however, no one is able to notice the film when it is closely laminated to the kraft paper material

Kraft Paper 60g, with brown color appearance, is the one of the most common used paper substrate film materials in flexible packaging field. Many coffee roasters choose the kraft paper materials out of environment friendly considerations.

VMPET 12, which means the vacuum metallized polyester film with most common thickness 12 microns (equals to 0.48 gauge)

LDPE 50, means low density polyethylene film, with thickness 50 microns, which is the most used inner sealing layer for the coffee bag. Actually, LDPE 50 is the lowest thickness applied for paper coffee packages. Sometimes, the customer may need a thickness inner LDPE film to achieve a stronger package.

thickness-187um-kraft-paper-VMPET12-LDPE-box-bottom-coffee-bag-min

The final thickness for this kraft paper foil laminate should be around 185 microns, with tolerance +-5%. Upon our experience, kraft paper bag with this thickness would be a little tough, that may cause difficulty in the filling process.

Coffee Bag Properties

1 Perfect print quality

The artwork is achieved in gravure printing which can print up to maximum 10 colors. With advanced print techniques and print defects inspection system, we are now outputing fantastic print effect for the customers’ artwork.

amazing-print-quality-of-artwork-on-kraft-paper-coffee-sachet

You are advised to watch the video below to have a further understanding on the print quality of 200grams ecofriendly kraft paper box bottom coffee bag .

2 Eco-friendly paper effect

You may check the kraft paper appearance as below picture, and it is really eye-catching attractive.

200grams eco-friendly foil materials coffee bag

3 Delicate Bag Making

The bag is achieved with delicate details, and you may check the smoothe zipper appearance in below picture. Some converters may not be able to output this smoothe zipper place.

Decilate-bag-making-kraft-paper-coffee-package

With the delicate details, this coffee bag is able to create a perfect impression for the branded products, and some consumers do like to buy a product out of its perfect package.

4 Fantastic Barrier Performance

As explained previous, this foil laminate is finalized with a layer of thin aluminum metal sheet, which is of the best barrier performance against oxygen and moisture vapor. Usually, the roasted beans should be well protected to keep the original flavor and fragrance in a prolonged period, to enable the beans well enjoyed by the end consumers. With this high barrier coffee bag, the roasted beans can be taken as 1 year shelf life.

5 Exquisite Standup Effect

The bottom of this 200grams ecofriendly kraft paper box bottom coffee bag is much like a box when the roasted beans are filled, and that will make the package well standup on the goods shelf, good for branding and sale.

200grams eco-friendly kraft paper pouch

6 Nice Mechanical Strength

This reinforced laminated foil is achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, upon customer requirements, and you may check the exact values of this foil material PET12/AL7/PET12/LDPE in the Technical Date Sheet part of this post.

In our daily QC work, there is an more easy and reliable method to check if the coffee bag strength is enough to meet the various conditions in the operations of filling, transport, loading and unloading, distribution. We perform drop test against each order, of course, the standard for this drop test should be decided against customer needs.

Here, we are going to drop the filled coffee bag from 1.6m high, for 5 times.

drop-test-check-bag-strength-kraft-paper-200g-coffee-package-min

You are advised to watch the video below.

After 5 drops for each bag, and none of them breaks, all are dandy.

7 Easy Tear Notch

There is not a rip zipper applied on this coffee paper sachet, so we just enable the tear with tear notch, as below.

200grams eco-friendly kraft paper doypack

8 Smooth Filling of coffee beans

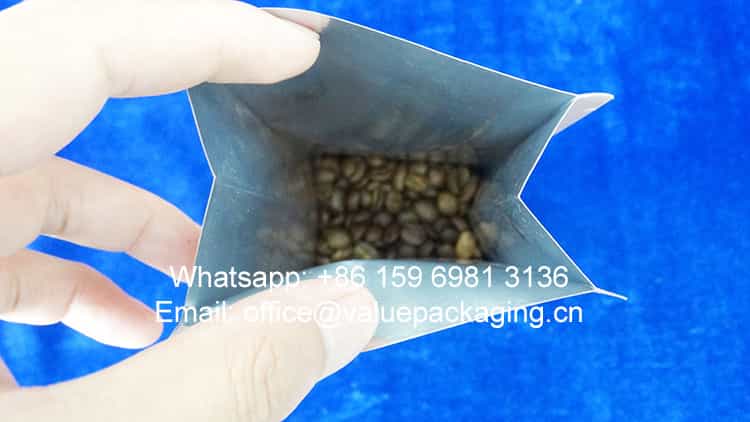

When the coffee package is opened on the filling machinery, a large opening can be achieve, as below picture.

676-eco-friendly-kraft-paper-foil-box-bottom-coffee-bag-with-large-opening-min

With the side gusset and bottom gusset, the bottom for this coffee bag is like a box (that’s why it is also called box pouch), that makes the fall of the roasted beans much more easily into the bag.

200grams eco-friendly kraft paper pouch

Package Dimension and Filled Level

The filled effect matters much, of course, that is depending on the package dimension and the products filled. Against 200grams of coffee beans, we perform the filling test here with density 370g/1000ml, and below picture shows the filled line, excellent!

filled-level-200grams-kraft-paper-roasted-beans-coffee-bag#287-min

Watch the video below to have a further understanding on the dimsion test and filled level.

Below dimension test report includes all the details, you can just forward to your customer for reference.

Coffee Bag-200g-Flat Bottom-W95xH260+Box Bottom30x2 mm -Package Dimension Test#287

Artwork Printing

A good creative artwork matters much more than most people expect, as most people tend to buy a product they feel good for.

200grams eco-friendly film materials coffee bag

For the printing produce in our plant, we are able to achieve the artwork in maximum 10 colors. With in-line print defect inspection system, more than 98% of the common print defects can be removed, you may have a further understanding by below video.

We will have to request a minimum order quantity of 10,000 bags against customer artwork. As to print each color, there will be a tank of printing inks offered to the rolling print cylinder. If we print only 5, 000 pcs, that will be huge waste of inks, film materials and labor.

one-cylinder-to-print-one-color

So if the customer is just looking for hundreds or thousands of coffee bag, he is advised to take from the stock items, like matte white coffee bag or matte black coffee bag, that should be much more cost-effective than custom printed bag.

Artwork Design Template

Here is the artwork design template for this 200grams ecofriendly kraft paper box bottom coffee bag , and you may just download and forward this file to your design for design.

Artwork Design Template 200 grams Coffee beans Bag W95XH260+Gusset60mm+Block Bottom

Technical Data Sheet

Here, we are going to share with you the test in our plant against some essential items, with values listed in this technical data sheet.

How to fill coffee beans into this flat bottom coffee pouch

Automatic filling machiney of 1kg coffee beans into block bottom pouch bag-min

This kraft paper block bottom coffee bag is with a large opening when expanded, and easier for the products filling and sealing operations. Here is a reliable filling machinery to achieve the packaging process of roasted coffee beans.

About the manufacturer

Qingdao Tongli Packaging has devoted itself to the manufacture of quality coffee bags for more than 10 years, with long-term customers around the world. You may just rely on us if you would like to get sustainable and reliable supply for your coffee packages.

Reviews

There are no reviews yet.