In the years passing by, more and more people are becoming concerned over the amount of plastic package produce into the environment, which has led to the widespread development of sustainable coffee packaging. Consequently, more roasters are reducing their carbon footprint by investing in compostable offee package and making a move towards zero-emission coffee roasting.

Based on the plant-based film materials in the current market, various compostable coffee bags are developed to meet the increasing requirements from different roasters. In current consumer market of coffee, there are popular package volume available like 250grams, 340grams ( equals to 12oz), 16oz (1lbs, equals to 454grams), 500grams, 2lbs (equals to 908grams) and 1000 grams.

So questions may arise from the roasters

- How does the compostable bag perform?

- Are the compostable bags strong enough to be good protection?

- How long shelf life can the bag provide for the roasted beans?

- Can the artwork be printed in flexo printing with water-based inks?

- How long would it take for the compostable bag to degrade in soil conditions?

- Is ther any certificate for the compostable bag?

Of course, we will answer each and every questions listed, and in this post, we are going to make a series of tests to check if the home compostable coffee bag is strong enough to be good protection for roasted beans. Anyway, if a bag bursts in the circling progress, that will absolutely a disaster for the roasters, and that situation should never be allowed from the beginning.

Above picture shows the side gusseted standing bag we developed for 1000 grams of coffee beans.

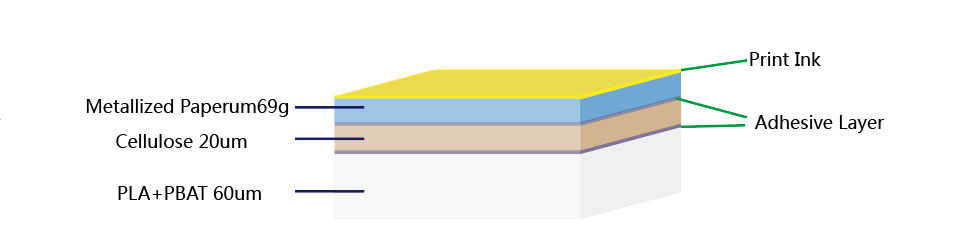

Home compostable composite Foil

The foil structure is Metallized Paper 69gsm/Cellulose20/PLA+PBAT60um, with graphic as below. This foil laminate can be further process into kinds of coffee bags, like pillow bag, box bottom bag, side gusseted bag, quad seal bag, and standing doypack, which are all working well for 1000 grams package.

The thickness of the compostable composite foil laminate should be around 150 microns.

Metallized Paper 69gsm

Metallized paper 69gsm should be the minimum weight per square meter we get for the converting. Working on the outside, it can be well intended for print substrate and supportive layer, which makes the final bag upstraight profile on the shelf.

Cellulose Film 20um

Cellulose film 20 um is the minimum thickness to be converted int multi-layer foil. With great tensile strength, high burst impact strength, the final foil laminate will be stronger when this cellulose film is applied.

PLA+PBAT 60 um

PLA+PBAT film means the blown film of PLA and PBAT resin mixed, which should balance the properties of final film, like stiffness, heat sealing, processing stability etc. The film we choose is proved to be working great for inner layer.

Compostable Zipperlock

Made from PLA resin, the re-seable zipperlock is available to be applied on the home compostable coffee bag.

Compostable Degassing Valve

Degassing valve, made from PLA resin, that can degrade into inorganic elements in home and garden conditions.

Drop Test

Drop test should be considered as one of the trust-worthy methods to check if a coffee bag is a good protection. It copys the way when a wee-standing coffee bag falls off the goods shelf by accident, and a heavy sudden force is caused the moment when the filled bag touches the ground ,and in that moment, a filled bag may burst if it is not strong enough. In our daily QC work, we usually perform the drop test from 1.2~1.6 meters from a certain times, against customer requirments.

Here, we work the compostable foil laminate Metallized Paper 69gsm/Cellulose20/PLA+PBAT60um into various types, and here you may watch the video below to understand the drop test on each of them, and see if any one fails

1000grams Pillow Pouch

The dimension for this 1000 grams pillow pouch is Width230XHeight340mm, with back sealing 10mm. Here is the video of drop test on this filled pillow bag.

60

1000grams Standing Doypack

The dimension for this 1000 grams standing doypack is Width240XHeight335+Bottom120 mm. Here is the video of drop test on this filled doypack. The doypack does not break even after 6 times of drop from 1.6 mters.

1000grams Quad Seal Bag

The dimension for this 1000 grams quad seal bag is Width140XHeight400+Gusset90 mm. Here is the video of drop test on this filled bag. The bag does not break even after 6 times of drop from 1.6 mters.

1000grams Side Gusset Bag

The dimension for this 1000 grams side gusset bag is Width150XHeight345+Side Gusset90 mm. Here is the video of drop test on this filled bag.

Anti-pressure Test

Anti-pressure test is to describe the ability of a air-flushed bag to withstand a certain pressure applied on top for a certain period of time. To simplify the anti-pressure test, in our QC test, usually a person is going to stand on the air-flushed coffee bag, and check if the bag burst. Against this ultimate test, the coffee bag will surely be ok as great protection fo the filling, transportation and distribution process.

Through below video, you may see I am going to stand on the air-flushed bag with zipperlock, and see if the bag bursts under so heavy pressure.

Ok, that’s the common tests in our daily QC work to check if the compostable coffee bag is well intended for 1000 grams of coffee beans. Upon the tests above, you can see how strong the compostable bag is, and surely it will be great protection for the coffee beans.

Of course, there are some other tests performed in our laboratory conditions, with details listed in the technical data sheet of 1000 grams box bottom pouch, as below.

so if you have any problems regarding the failure of coffee bag, you just reach us for further assistance, we are surely of help.