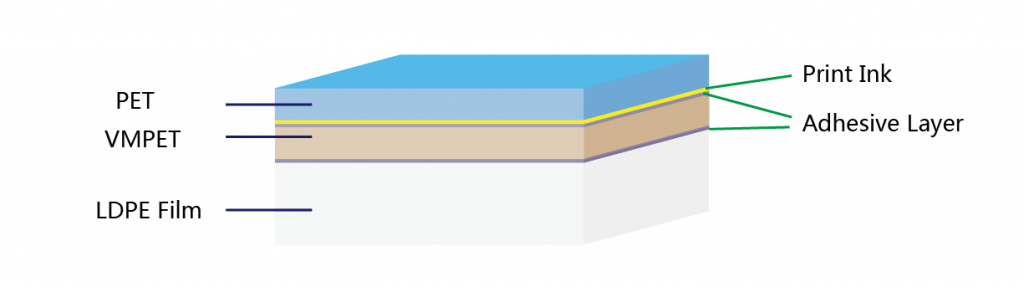

LDPE film is short for low density polyethylene film, which is the most common used inner sealing film for multi-layer flexible packaging in various applications. For most branded products, there will be a particular logo printed on the package, to achieve that purpose, usually a fine substrate film will work as the outside print base film, and then this printed film will be further laminated with the inner LDPE sealing film, to achieve various amazing packages for kinds of consumer products.

Just take the re-sealable coffee bag as below picture, the zipperlock and degassing valve will be melted onto the inner LDPE layer with great adhesion, anyway the fall-off of zipper or degassing valve will cause so bad a failure to the coffee bag package. The final coffee bag will be achieved with fine air-tight property through the excellent sealing property of the inner LDPE layer, to protect the inside coffee beans in a prolonged shelf life.

so, LDPE film matters.

Currently, LDPE film occupies the large majoriety among all the flexible packaging film materials. With so many brands of LDPE resins available in the commercial market, with quite different performance, the final performance of LDPE film may be achieved in a huge difference. Working as the inner layer, LDPE film is in close touch with the various products, not only the migration of chemical elements will have to be well controlled to meet the regulations of human food safety, but also the film will have to meet the vaious requiements of protection for different products.

Of course, LDPE film matters so much.

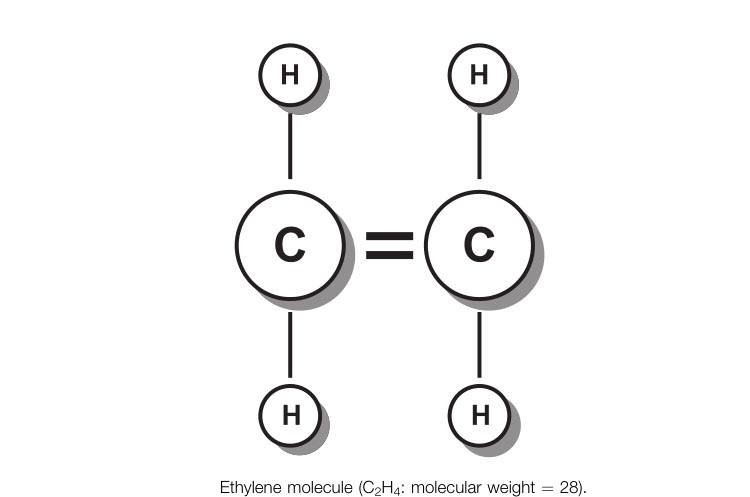

When we talk about LDPE film, we will have to start with the ethylene molecular and its polymer, as this is the most fundamental elements for the various performance of final LDPE films.

Molecular

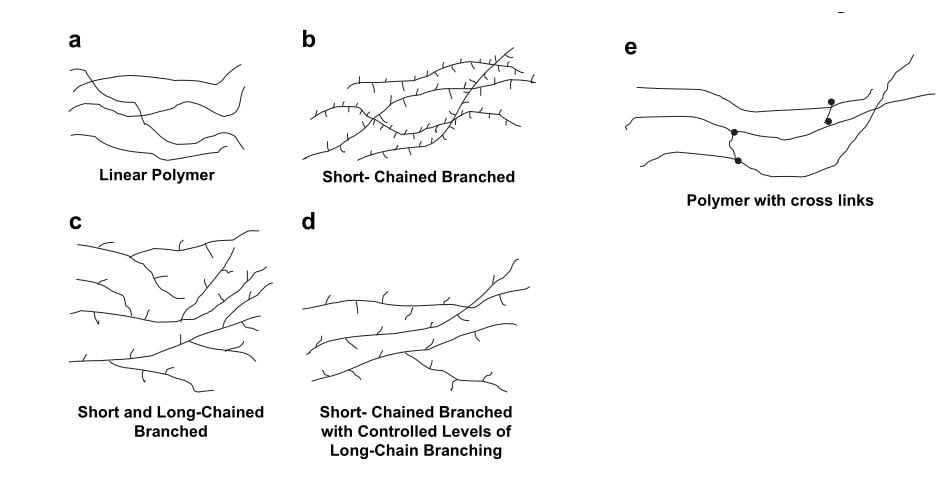

Ethylene is a colorless gas with a slightly sweet smell and is obtained by cracking (ther- mal decomposition) ethane at high temperatures (800 ℃) in a cracker or steam furnace. Under certain pressure, at the right temperature and with an initiator, polyethylene can be produced, with different polymer chain structure, with some of the most common ones as below.

The performance for the polyethylenes of these different chain structures differs much, and they can be commercialized into different brands, in each particular application, and in some cases, there will be mixes of these different brands to achieve a particular performance in actual application.

Mechanical Property

The mechanical property should be the first thing to consider when LDPE film is intended for packages. Here are some of the common tests which are performed under our laboratory conditions

- Tensile Strength

- Elongation Rate

- Coefficient of friction

- Tear Strength

- Gloss/Haze

- Wetting Tension

- Seal Strength

- Thermal Shrinkage

You may find some typical values of this inner sealing LDPE film 80 microns, with our technical data sheet attached, and the video link behind the value shows the progress for this specific test.

Migration

The test items of the samples will comply with the requirements stated in Regulation (EC) No 1935/2004 of the European Parliament on materials and articles intended to come into contact with food, and Commission Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food.

| Description of Monomers / Additives | PM Ref. No. | CAS Ref. | SML(mg/kg) |

| BPA | — | 1980/5/7 | 0 mg/kg |

| PAA | — | 9003/1/4 | 0 mg/kg |

Global Migration:

Limits and testing procedures in accordance with (EU)10/2011 (Germany: Measurements according to § 64 LFGB, part B 80.30 1, 2, 3 (EC)).

The migration limits (10 mg/dm²) are in compliance under the following conditions:

| Simulant | Food Type/Food Contact Conditions | Test Conditions | Overall Migrations (mg/dm3) |

| A Ethanol 10% | Distilled water | 10days at 40C | <1 |

| B Acetic Acid 3% | 3% Acetic Acid(W/V) Aqueous Solution | 10days at 40C | <1 |

| C 10% Ethanol | 10% Ethanol(V/V) Aqueous Solution | 10days at 40C | <1 |

| D Fatty Food | Fatty Food Simulant | 10days at 40C | <1 |

You may find the migration test report executed by china third-party inspection, against different request of chemicals migrations.

Alcohol Resistance

High Temperature Resistance

Some of the laminated pouch packages may will have to pass sterization in boiling water, and the inner LDPE film will have to be able to withstand the high temperature treatments without damage or contamination to the inside food products.

Here we are going to perform the test of boiliing water treatment with aluminum foil structure spout doypack (Foil laminate PET12/AL7/PET12/LDPE80) immersed in water conditions of 105 ℃, for 30 minutes, and by below screen, you can check the settings for this test.

After 30 minutes of hot water treatments, actually, each and every of the spout doypack keeps the original shape and status. without any damage, and able to stand up straight with great profile.

Here, you may watch the video below to understand the test progress.

Alkaline Resistance

Bleaching powder is of strong alkaline corrosive performance, which is usually intended to remove the natural colour of fibres, yarns, other textiles, and paper.

So we performed this test with laminated pouch (foil structure PET12/BOPA15/LDPE100) with bleaching powder filled, and then store it in room conditions, without sunlight direct exposure.

18 months passed, actually the laminated pouch is still fine and dandy, without any damage or the degradation of the artwork printing. That proves the pouch materials is of great alkaline resistance performance, which can also extened its application for many other products, like hand wash liquids, soap, laundry detergent liquids, laundry detergent powders, windshield washer fluids etc.

You are advised to have a further understanding on the final status of the laminated pouch after 18 months of direct contact with bleaching powder.

Acid Resistance

Grease Resistance

For some products that contains high percentage of oil, like cooking oil, oil condiments etc, it is essential to make the inner LDPE film with excellent grease resistant. Our company is now producing so many sachets for oily condiments for hot pot purpose in China market.

Oxygen Tranmission Rate

The barrier performance of LDPE film is very bad, usually with oxygen transmission rate ranging from 1500~2500 cc/m2*24hours, so LDPE film will never be taken as high barrier package along for many products. Of course, there are some modification with some barrier resin, like EVOH or PA resin, which can be well intended for some high barrier package, and we will give further introduce on them in future posts.

Machine Orientation

Below table shows the tensile strength and elongation rate of an inner sealing LDPE film with thickness 80 microns (equals to 3.15 mil). You can check LDPE film is very easy to be tensiled at a weak strength and extend to a very high elonagtion, which inhabit it to be used for printing substrate film purpose.

| MD | Maximum Tensile Strength(N) | Tensile Strength (Mpa) | Elongation Rate (%) |

| #1 | 25.53 | 21.28 | 628.84 |

| #2 | 24.79 | 20.66 | 640.49 |

| #3 | 22.37 | 18.64 | 590.28 |

| #4 | 24.89 | 20.74 | 587.34 |

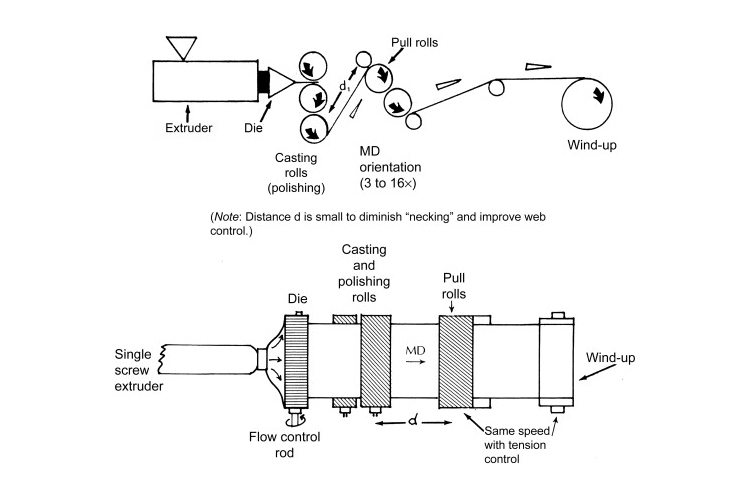

However, with the fast development of machine orientation technology, MDOPE (short for machine direction orientation polyethylene) film starts to playing a critical role in the printing substrate for mono materials laminated pouch which can be fully recylable.

Above graphic shows the theory of machine direction orientation technology in the film casting and wind-up operation. After machine direction orientation, the tensilse strength of MDOPE film sharpes to a much high level, which may not cause the distort of customer artwork in the printing process. Of course, we will share more on the performance and application of MDOPE film in the future.

Ok, that’s the basic things we need to talk about LDPE film. Anyway, LDPE is modified with so many variants to meet the various requirements for different products. You are welcome to reach us wheneve you have a problem for your packages.

Nice day.