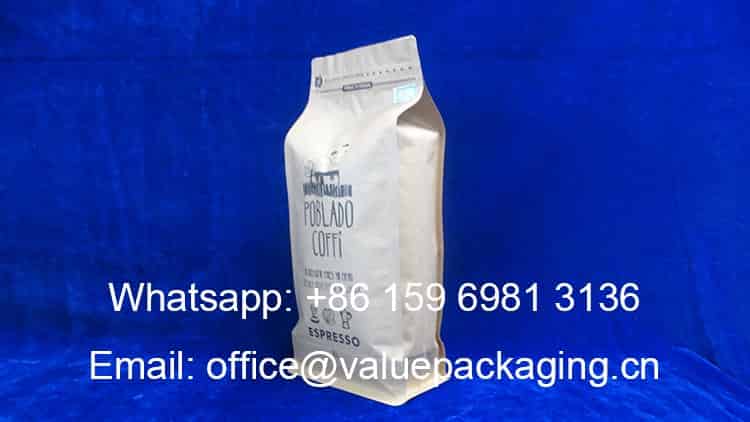

Kraft paper is widely used in coffee packaging, including coffee bags, cups, labels, boxes, cup sleeves, and mailing envelopes. It is becoming a staple in the coffee sector as more businesses seek sustainable packaging for their coffee products. Some roasters would love to combine their amazing artwork design with kraft paper coffee bags to create powerful marketing and communication with their customers.

As a well-known flexible converter located in Qingdao, China, we are here to explain how to print a custom logo onto kraft paper coffee bags and the printing techniques that can help you realize customer expectations.

Stamping

If you start your coffee business and like to brand your own coffee, and are not sure how many bags of coffee you can sell, a stamp of your logo may give you complete control over the number of bags you print.

You may buy anonymous paper bags with an MOQ of 50 pcs on Amazon and stamp on the necessary bags when an order occurs. This stamping will help you cut each penny spent on your marketing strategy.

Stamping the paper bags is very simple, as kraft paper is very absorbent to inks. After stamp printing, the bag can be immediately used for packing.

Hot Stamping Foil Printing

The operation of hot stamping foil printing is quite like that of a normal stamp. However, it can achieve much more. It utilises metallic foil and heat transfer under a particular pattern mold (a stimulating stamp) to achieve logo printing. As you can see, the golden logo is printed on the paper carrier bag. The pattern mold has to be made against the customer logo.

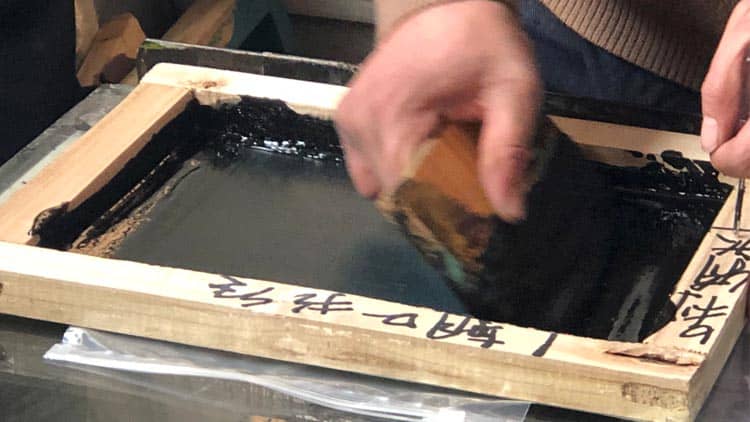

Silk Screen Printing

Silk screen printing, sometimes called screen printing, is one of the most popular techniques for applying ink to paper, non-woven fabrics, plastics, and aluminum cans. Through screen printing, more ink can be printed onto the porous texture of the paper substrate to present a better solid printing effect.

A printing frame is created to accommodate the logo pattern, and the inks can transfer through the porous holes of the logo pattern, without contaminating other places. The operator can wipe the ink with a scraper, and the logo is printed onto a kraft paper coffee bag.

Flexographic Printing

Flexographic printing is a variation of letterpress printing used mainly for packaging applications. It can be well applied to various substrate materials such as plastic films, foils, coated and uncoated paper, paperboard, corrugated board, and non-woven fabrics. A set of elastomeric printing plates with fast-drying ink is wrapped around rotating cylinders on a web press, which allows large orders to run with few interruptions.

When intended to print on a kraft paper coffee bag, flexographic printing will achieve a similar quality as gravure printing. However, it is much more eco-friendly. Water-based inks can be applied in production, with much fewer VOCs emitted to the environment.

Please note that, unlike stamp printing and screen printing, the logo will have to be printed on the paper roll before the bag is finally made, which will allow large orders to be produced at lower costs.

Gravure Printing

Gravure printing is considered one of the most sustainable forms of printing because the cylinders are extremely durable and can be used for high-volume jobs over a long period of time. This should be the ideal solution when the customer wants to print their artwork in high image quality at the lowest cost. In our manufacturing plant, there are 3 gravure print press lines available, continuously serving as a reliable and quick-time supply for the customers’ needs.

Digital Printing

Digital printing is well-suited for short print runs or sample production of the kraft paper coffee bag without the customization of print cylinders. It allows customers to test the market with a very low MOQ without breaking their bank. We are offering digital printing services on kraft paper coffee bags with an order quantity of fewer than 5,000 pieces, as the unit price will be more favorable if the kraft paper coffee bags are printed using the gravure method.

From the human naked eye, it is very difficult to tell a bag printed by digital from one printed by gravure, so you can get settled on digital printing for the start of your business on powerful marketing and branding.

Some customers may like to see the real quality of their artwork printed on kraft paper coffee bags before moving into mass production. Under these circumstances, digital print should be the best choice at a very low cost.

Summary

Coffee roasters are advised to fully utilize the advantages of different printing techniques to finalize their powerful kraft paper coffee bags during different business periods.

Here, we summarize the general information and use of these 6 printing techniques in the table below, and hope you can boost your business based on our supply ability.

| Printing Technique | Advantages | Order Quantity | Overall Cost | Unit Price | Business Period |

| Normal Stamping | Simple and flexible, customer can print at their site | Not Limit | $ | $$ | Startup or sample testing |

| Digital Printing | superior print quality for lower quantity | 1~3000 pcs | $$$ | $$$$$ | Startup or sample testing |

| Hot Stamping Foil Printing | Flexible and gold highlight | Larger than 1,000 | $$ | $$ | Marketing Testing |

| Silk Screen Printing | Simple and flexible, customer can print at their site | Not Limit | $$$ | $$ | Startup or sample testing |

| Flexo Printing | High print quality for large order | larger than 30,000 | $$$$$ | $ | Business Expansion |

| Gravure Printing | Superior print quality for large order | larger than 30,000 | $$$$$ | $ | Business Expansion |

As a reliable converter and supplier of superior-quality coffee bags, we have been refining our craftsmanship and supply chain to create true value in the coffee packaging field. We have a professional team to analyze your needs and finalize your expectations at the most favorable cost. You are welcome to contact us for further ideas whenever you have any problems regarding coffee packaging.