This kind of pillow pouch is quite popular with customers in the puffed food field. Furthermore, BOPP/VMPET/LDPE material performs remarkably well. The pillow pouch material has been strictly selected and has excellent physical properties, such as anti-stretching, anti-puncture, etc., which can resist various physical impacts from the outside world to ensure that the items are safe and undamaged in a complex logistics environment.

At the same time, it also has a good feature in printability, which can be customized according to customer needs for a variety of exquisite patterns and text, enhancing the added value of products and market appeal.

As a well-known packaging manufacturing company located in Qingdao, China, we are trying our best to provide the best services in the packaging film materials field in the world market. The packaging film materials are listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- Vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We are devoted to creating an attractive pillow pouch for puffed food that increases product sales and establishes a good brand image.

In this post, we will analyze the exact foil materials of this 70g puffed food pillow pouch, hoping it could serve as a reference for your products.

Ok, let’s take a look at the details of this 70g pillow pouch for puffed food.

Packaging Foil Materials

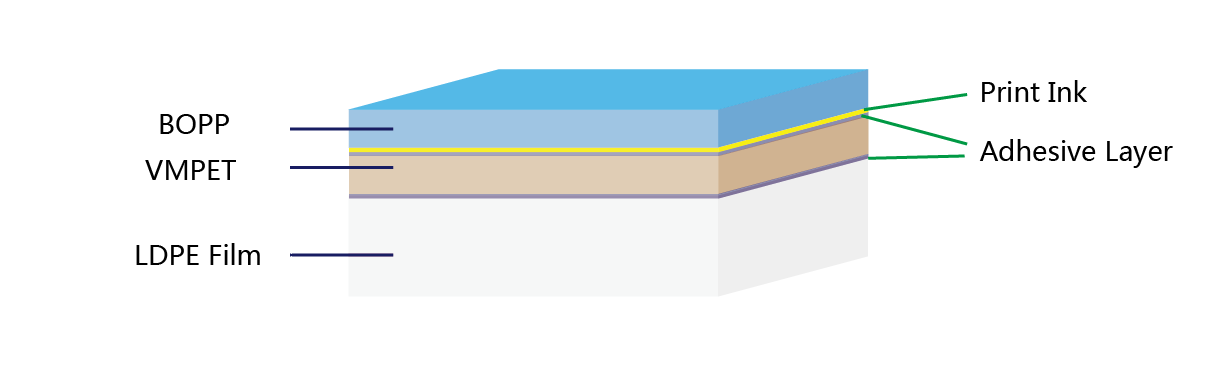

This foil material is a reinforced structure with excellent properties for puffed food packages. The foil structure is BOPP/VMPET/LDPE, with a graphic as follows.

The film material of the puffed food pillow pouch is made of three layers. The outside BOPP film acts as the print substrate film, the VMPET film acts as the middle supportive layer, and finally, the LDPE film acts as the inner sealing layer. The thickness of the LDPE film should be adjusted to suit the requirements of a 70-gram puffed food pillow pouch.

Because of its excellent barrier properties and mechanical strength, this material structure is very suitable for inflatable food packaging, which can ensure the freshness and safety of food.

BOPP Film

BOPP (biaxially stretched polypropylene film) is a film formed by biaxially stretched polypropylene material, which has excellent mechanical properties, transparency, and gloss, as well as excellent moisture resistance and gas barrier properties.

VMPET Film

VMPET (vacuum aluminized polyester film) combines the characteristics of plastic film and the characteristics of metal, with a surface metallic luster, and can block light, gas, and water vapor. It can also replace aluminum foil. In addition, VMPET film also has good chemical stability; it can resist the corrosion of most acid and alkali substances.

In composite packaging, VMPET film is often used as an intermediate layer, with its aluminum coating providing light shielding and UV protection, extending the shelf life of the contents and enhancing the brightness of the film.

LDPE Film

LDPE means low-density polyethylene film, which is the most used inner sealing layer for puffed food. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. LDPE is nontoxic, non-contaminating, and has a high degree of break resistance.

Most importantly, the LDPE membrane can be modified against the requirements of specific products and finalize the package with great seal strength and protection. The thickness of the LDPE membrane film will be decided against the particular application.

Thickness

As you can see from the below picture, the overall thickness of this 4-sided sealed pouch is 0.156 mm, which equals 156 microns for this laminated foil.

Mechanical Property

The BOPP/VMPET/LDPE composite packaging bag has good tensile strength. BOPP: This layer increases the mechanical strength and heat resistance of the package but also helps to improve the transparency of the package.

The VMPET layer provides a high tensile strength so that the bag is not easily destroyed. When it is subjected to a certain tensile force. For example, when handling bags filled with heavy items, the PET layer can withstand the tension generated by the weight of the item, preventing the bag from tearing on the handle or other stress areas.

The LDPE layer has lower tensile strength than the PET layer, but its presence increases the overall flexibility of the bag. This means that when subjected to a small tensile force, the bag can have a certain degree of tensile deformation without breaking immediately so that the bag can adapt to a certain range of external force changes

We put the mechanical property of this 70-gram puffed food pouch as our top priority in our manufacturing plant. Serious measures are taken in our QC system to ensure each order is finalized with the expected result.

To put it simply, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces.

Barrier performance

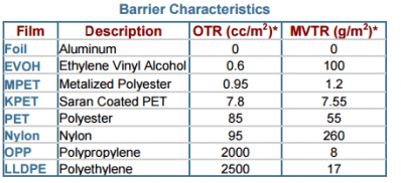

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (oxygen transmission rate). The table below shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, BOPP/VMPET/LDPE foil laminate will be able to meet most of the requirements for 70-gram puffed food. WVTR (short for water vapor transmission rate) and OTR (oxygen transmission rate) are evaluated for this laminated foil, with typical values listed in the table below.

| Item | Standard | Unit | Typical Value |

| g/m²/24hr | ASTM E 96 | cc/m²/24hr | |

| cc/m²/24hr | ASTM D 372-99 | cc/m²/24hr |

Technical Data Sheet of 70g puffed food pillow pouch

Here, we attach the specification sheet of this 70g puffed food pillow pouch based on foil laminate BOPP/VMPET/LDPE.

Mort tests are included in this specification sheet, with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m²)

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m²/24 )

- Oxygen Transmission Rate (cc/m²/24 )

Learn more about this foil laminate on our company site.

More Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages, which leads to a more eco-friendly activity of the business. Upon the recent investigation of the nut market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Compostable Packaging Materials

The compostable packages are based on plant-based fibers like cellulose or biomass like cornstarch, cassava, or sugarcane. The resins derived from these resources are usually named “biopolymers,” which can break down into inorganic elements under the functions of algae, bacteria, and other microorganisms.

At present, we have developed several compostable foil materials that can be intended for powdered food, as shown in the list below.

- Cellulose/Metallized Cellulose/PLA+PBAT Film

- Metallized Paper/Cellulose/VMPET/PLA+PBAT Film

- Kraft Paper/Metallized Cellulose/PLA+PBAT Film

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, fully recyclable material sachets and rolls are flooding the market for lightweight product packages at much lower prices. Mono-material packages mean each layer of the multi-layer foil is made of the same resin, which can be easily processed in the human recycling system and reused for other applications. This recyclable materials sachet largely reduces the rate of plastic polymer film packages ending up in landfills.

Nowadays, we have developed some bags based on single-resin film materials that can be found in good application for roasted sunflower seeds. We will give a further analysis in future posts.

That’s all for now. If you have any questions, please feel free to contact us. Enjoy your time!