This kind of sachet is quite popular with customers in the coffee powder sachet field. Instant coffee bags made of PET/VMPET/LDPE materials have many benefits. PET materials have high strength and impact resistance, which can effectively protect coffee powder from damage during transportation and storage. VMPET is an aluminized PET film that provides good barrier properties and can effectively prevent the penetration of oxygen, moisture, and light, thus maintaining the freshness and flavor of coffee. As the inner material, LDPE has good low-temperature heat sealing and antistatic properties, which are suitable for powder food packaging to ensure that coffee powder will not leak during the packaging process.

Instant coffee powder packaging bags are usually small and light in weight. For example, some portable instant coffee powder bags, such as Nestle, are only a few centimeters square and weigh only a few grams. Consumers can easily put it in a backpack, pocket, or handbag. This is very useful for travelers and office workers.

In this post, we will analyze the exact foil materials of this 25g instant coffee sachet, hoping it could serve as a reference for your products.

Well, let’s have a look at the details of this 25g volcanic coffee powder sachet.

Packaging Foil Materials

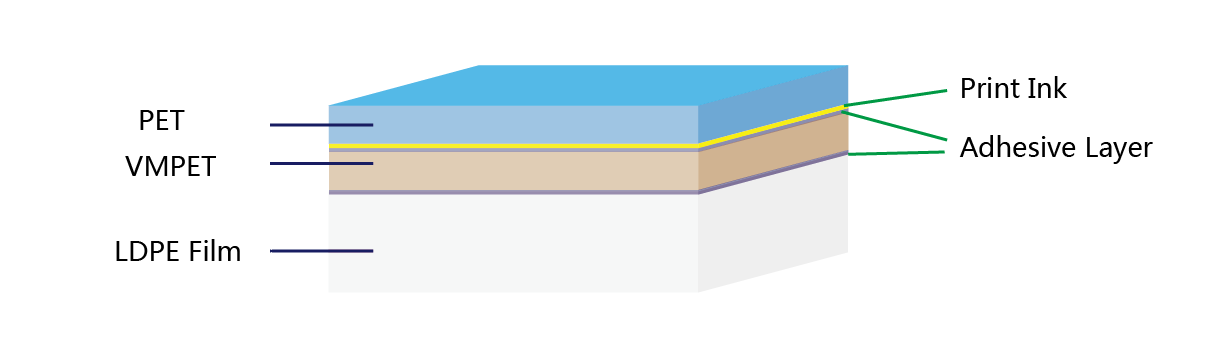

The structure for instant coffee powder is PET/VMPET/LDPE, with a diagram as follows.

The film material of the coffee powder sachet is made of three layers. The outside PET film acts as the print substrate film, the VMPET film acts as the middle supportive layer, and finally, the LDPE film acts as the inner sealing layer. The thickness of the LDPE film should be adjusted to suit the requirements of a 25-gram coffee sachet.

An instant coffee powder bag can be a good seal for coffee powder. Compared with bulk coffee powder, it can effectively prevent coffee powder from moisture and oxidation. For example, in a humid environment, bulk coffee powder can easily absorb moisture from the air, resulting in caking and affecting the taste and quality of the coffee. The packaging bag can isolate the air and keep the coffee powder dry and fresh.

At the same time, the packaging bag is usually marked with shelf life and other information, so consumers can clearly know the storage period of coffee powder, making it easy to manage inventory.

PET Film

PET (polyethylene terephthalate) is an excellent polymer material with high transparency, good luster and mechanical strength, and a wide temperature range, and it can be used stably between -70 ° C and 120°C. It also has excellent barrier properties and can effectively block gas, water vapor, and odor while having a good tolerance to a variety of chemicals. In addition, PET has excellent electrical insulation and weather resistance, good processing performance, and can be manufactured through a variety of molding processes. PET materials are also recyclable, meet environmental requirements, and are widely used in many fields such as packaging, electronics, automotive, and textiles.

VMPET Film

VMPET (vacuum aluminized polyester film) combines the characteristics of plastic film and the characteristics of metal, with a surface metallic luster, and can block light, gas, and water vapor. It can also replace aluminum foil. In addition, VMPET film also has good chemical stability; it can resist the corrosion of most acid and alkali substances.

In composite packaging, VMPET film is often used as an intermediate layer, with its aluminum coating providing light shielding and UV protection, extending the shelf life of the contents and enhancing the brightness of the film.

LDPE Film

LDPE (low-density polyethylene film), which is the most used inner sealing layer for coffee powder. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. LDPE is nontoxic, non-contaminating, and has a high degree of break resistance.

Most importantly, the LDPE membrane can be modified against the requirements of specific products and finalize the package with great seal strength and protection. The thickness of the LDPE membrane film will be decided against the particular application.

Thickness

As you can see the thickness of this coffee powder sachet in the below picture, the thickness of this coffee powder sachet is 0.176 mm, which equals 176 microns for this laminated foil.

Mechanical Property

The mechanical properties of PET/VMPET/LDFPE materials are as follows. The PET layer has high tensile strength, bending strength, and impact strength; its impact strength is 35 times that of other films, and it has good folding resistance. The mechanical properties of PET are less affected by temperature, and it also has good wear resistance, fatigue resistance, and dimensional stability.

The VMPET layer has excellent mechanical properties, good flatness and stiffness, high tensile strength, and high elongation.

The LDPE layer has a tensile strength of 714 MPa, with good flexibility and extensibility, but its mechanical strength, moisture insulation, gas insulation, and solvent resistance are relatively weak.

We put the mechanical property of this 25-gram coffee powder sachet as our top priority in our manufacturing plant. Serious measures are taken in our QC system to ensure each order is finalized with the expected result.

To put it simply, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces. You can watch a video similar to this.

Barrier performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (water vapor transmission rate) and OTR (oxygen transmission rate). The table below shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, PET/VMPET/LDPE foil laminate will be able to meet most of the requirements for 25-gram coffee powder. WVTR (water vapor transmission rate) and OTR (oxygen transmission rate) are evaluated for this laminated foil, with typical values listed in the table below.

Technical Data Sheet of 25g coffee powder sachet

Here, we attach the specification sheet of this 25g coffee powder sachet based on foil laminate PET/VMPET/LDPE.

Mort tests are included in this specification sheet, with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m²)

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m²/24 )

- Oxygen Transmission Rate (cc/m²/24 )

Learn more about this foil structure on our company site.

More sustainable materials options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages, which leads to a more eco-friendly activity of the business. Upon the recent investigation of the nut market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

For compostable materials packaging, you can watch a video similar to this.

The compostable packages are based on plant-based fibers like cellulose or biomass like cornstarch, cassava, or sugarcane. The resins derived from these resources are usually named “biopolymers,” which can break down into inorganic elements under the functions of algae, bacteria, and other microorganisms.

At present, we have developed several compostable foil materials that can be intended for powdered food, as shown in the list below.

- Cellulose/Metallized Cellulose/PLA+PBAT Film

- Metallized Paper/Cellulose/VMPET/PLA+PBAT Film

- Kraft Paper/Metallized Cellulose/PLA+PBAT Film