Pillow bag is a major part of condiment packaging in the market at present. Made of 100% recyclable polyethylene film, it has high recyclability and helps to reduce environmental pollution. Pillow bags can protect condiments during distribution, which is more cost-effective. In addition, creative artistic design can be printed on all sides of the pillowcase, including all the information of brand and sales, which makes the final packaging more attractive to consumers.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the packaging film materials in the market, which are listed below.

- Fossil chemical polymer films

- Aluminum foil metal sheet

- Vacuum metalized film materials

- Ceramic film substrates

- Plant-based biopolymer materials

- Biodegradable film materials

- Compostable substrate films

- Fully recyclable substrate films

We are committed to creating story-telling packaging, allowing food to “jump” into people’s hearts from shelves, increasing product sales and establishing a good brand image.

In this article, we will analyze the exact foil material of this 50 g black pepper pillow bag, which will help this food manufacturer achieve greater market success.

Packaging Foil Materials

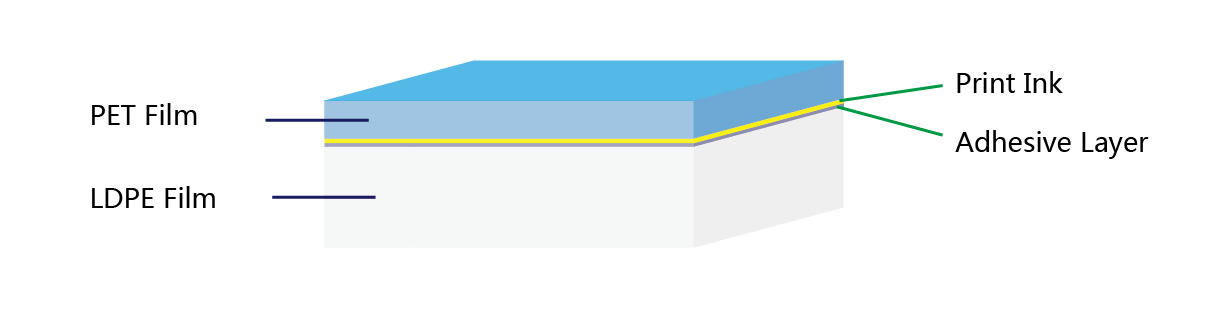

We adopted a better foil structure with excellent packaging performance. Usually we call it PET/LDPE. As shown in the following figure.

It consists of two layers, with the external PET film as the printing base film and the LDPE film as the internal sealing layer. In the food packaging field, PET and LDPE are two commonly used materials, and their composite structures are often used to improve barrier properties, mechanical strength and sealing performance.

PET Film

PET film, sometimes BOPET film, is one of the most commonly used print substrates in flexible packaging area. It is of great printability, mechanical strength, processing stability, high temperature resistance, and grease resistance

LDPE Film

LDPE film is short for low density polyethylene film, which is the most common used inner sealing film for multi-layer flexible packaging in various applications. Low-density polyethylene (LDPE) can be fully recycled.

Thickness

In the picture below, we can see that the overall thickness of this pouch is 0.138 mm, which means the thickness of this foil laminate should be 0.069mm (equals 69 microns).

Through reasonable thickness design and structural optimization, PET/LDPE composite packaging can not only ensure food safety, but also reduce the material cost by 15%-20%, and meet the production efficiency requirements of high-speed bag making (120-180 bags per minute).

Wonderful Printing Effect

PET material has high transparency and gloss, which can clearly display the food in the package and enhance the attractiveness of the product. This feature is particularly important for food packaging, because it allows consumers to intuitively see the appearance and quality of products.

Great Mechanical Properties

Pillow bag packaging will protect the product during filling, transportation and distribution. High tensile strength and impact resistance, the products are durable, can withstand certain external force extrusion and collision, and are not easy to break. This enables PET packaging to effectively protect food and reduce the risk of damage during transportation and storage. In the event of unexpected vibration during transportation or the package falling off the shelf, the spout package must not be broken.

We put the mechanical properties of this 50-gram black pepper powder packaging bag at the top of the factory’s manufacturing. Our quality control system has taken strict measures to ensure that every order can achieve the expected results.

In short, the compression test of the full package is one of the most reliable methods to check whether the package will break under strong force.

Here, we will put 50 peppers into this bag, and use a pressure value of ≥15kg. When the bag body bears a pressure of ≥15kg. Check whether the package is cracked or not, and whether there is any false seal or air bubble at the heat sealing part.

In our daily work, there is also a reliable method to check whether the strength of the bag is enough to meet various conditions in filling, transportation, loading and unloading and distribution. We will conduct a drop test on each order. Of course, the standard of drop test should be determined according to the needs of customers.

Barrier Performance

The following list is the general basic formula types of black pepper.

- Flavoring enhancer

- Anticorrosive and anti-caking agent

The outer layer of PET provides an ultraviolet blocking rate of ≥95%, the inner layer of LDPE realizes anti-pollution sealing, and the oxygen permeability of composite structure is less than 0.5 cm/m 24h ATM, which can effectively protect the storage period of black pepper.

The barrier properties of multi-material laminates were evaluated by WVTR (abbreviation of water vapor permeability) and OTR (oxygen permeability). The following table shows the typical values of WVTR and OTR of common basement membrane materials.

With the continuous updating of packaging, some packaging with better barrier performance and appearance are more favored by customers.

- PET/Aluminum/LDPE

- PET/VMPET/LDPE

- PET/YYVMPET/LDPE

Technical Data Sheet of 50-gram black pepper powder pillow bag

Here, we attach the specification sheet of this 50g black pepper powder pillow bag, which is made of foil laminated matte PET/LDPE.

More tests are included in this specification sheet, with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to know more about this kind of PET/LDPE, you can read it here.

More Sustainable Materials Options

In recent years, with the increasing burden of fossil chemical polymer materials discarded into our environment, people pay more and more attention to more sustainable use of renewable materials. The demand for sustainable packaging is unprecedented, which leads to more environmentally friendly activities of enterprises. According to a recent survey of condiment market, more and more consumers are more likely to buy products that are conducive to environmental protection and sustainable use of recycled materials.

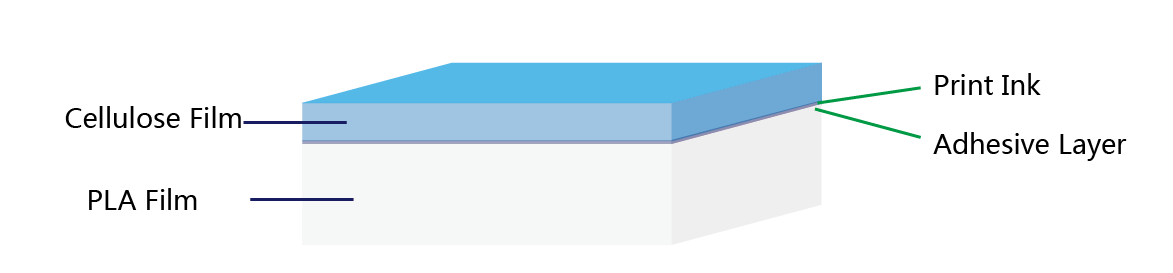

Compostable Packaging Materials

The compostable packages are based on plant-based fibers like cellulose, or bio-mass like corn starch, cassava, or sugarcane. The resins derived from these resources are usually named bio-polymer, which can break down into inorganic elements under the functions of algae, bacteria, and other microorganisms.

Transparent PET has become the mainstream choice, and its high recovery rate (global recovery rate will reach 35% in 2025) and compatibility support the whole industrial chain cycle. Replacing traditional color bottles can reduce the sorting cost by more than 20%.

The permeability of recycled PET (RPET) in food-grade packaging has exceeded 20%, and aseptic packaging has achieved 100% rPET application, reducing the consumption of primary plastics and reducing carbon emissions by 44.6%.

There are more cases of PP replacing PS (such as Mengniu Youyi C nonstandard packaging), and the transportation energy consumption is reduced through lightweight design of materials.

Sustainable packaging design is the new direction of FMCG industry, involving material selection, design optimization, production process improvement and consumer education. By implementing these strategies, enterprises can not only reduce the impact on the environment, but also enhance their brand image and attract consumers who pay more and more attention to environmental protection.

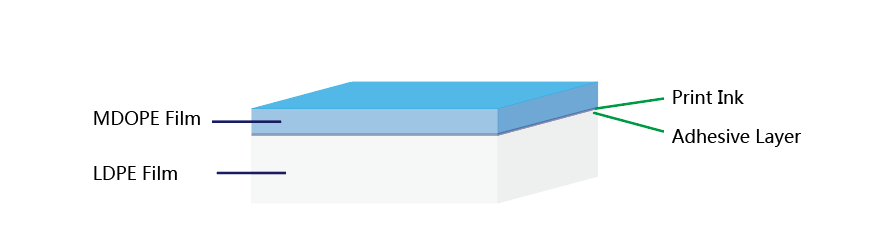

Fully Recyclable Mono Materials

The packaging of bagged products of Nestle Purina Guanneng brand changed from the original PET/AL/PE structure to a single recyclable design structure, and VMOPP was used instead of aluminum foil structure to maintain its barrier performance, which increased the recycling value of the packaging.

Some of our customers are moving to fully recyclable mono-material bags.According to the industry data in 2025, the production cost of optimized PET single material packaging decreased by 12%, and the bag breakage rate was controlled below 0.05%.

Now it’s the end. You are welcome to reach us if you have any questions regarding powder pouches. Have a nice day.