In the coffee sector, more and more specialty coffee roasters are starting to invest in sustainable PE coffee packaging. They believe sustainable polyethylene coffee bags will not only leave less impact of their business activities on the environment, but also make their branding more acceptable to eco-conscious consumers and more valuable in the market.

Say No to traditional unrecyclable foil bags

For decades, plastic packaging has been a major source of environmental pollution and global warming. Plastic packages left in the wild pollute the air, water, soil, and seas and release microplastics that may harm our food and health system in the long run.

Traditional coffee bags are usually made of foil laminates based on different materials, such as kraft paper, aluminum foil, metallized films, polyethylene film, ceramic film, and polyester films, which makes them difficult to recycle and reuse. Most traditional foil coffee bags can only be landfilled, incinerated, or left in the wild, which is not sustainable.

What are sustainable Polyethylene coffee bags?

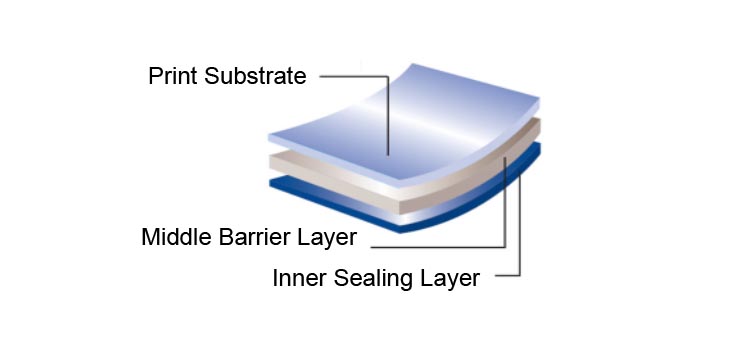

The above figure shows a coffee bag’s common triplex multilayer foil laminate.

The outer film layer works as the print substrate, which carries the information of a custom artwork. Previously, only BOPP (short for biaxially oriented polypropylene) film, PET (short for Polyethylene terephthalate) film, or Nylon film were available. Now, both BO-PE and MDO-PE films are starting to serve as outer print layer.

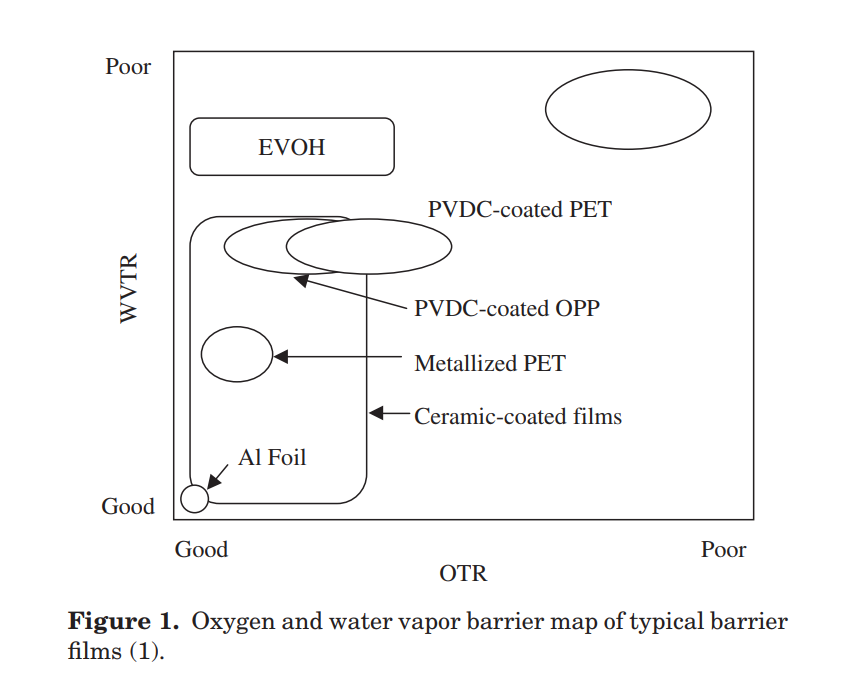

The middle layer is a barrier against oxygen, grease, contaminants, and moisture. Previously, only vacuum metallized film, AlOx-coated polyester film, or aluminum foil were feasible for this purpose. However, based on the development of polyethylene film, biaxially oriented coextruded EVOH-PE film, and PVA-coated HDPE film have fine barrier properties for this purpose.

LDPE film, sometimes blended with LLDPE, are the most common sealing layer for coffee bags.

So, all three layers of this coffee bag foil laminate can be made of a single polymer—polyethylene, which is generally called a mono-material coffee bag. This bag can be easily recycled into the production of pellets and newly made into other plastic products, like trash bins, trays, containers, etc., rather than landfills. This is going to build a sustainable circular economy.

So, we will explore each polyethylene film used to produce sustainable PE coffee packaging in depth.

Polyethylene Films Intended For Sustainable Coffee Bags

BO-PE Film

BOPE stands for biaxially oriented Polyethylene film, which has refined stiffness, tensile strength, printability, and heat resistance after biaxial orientation. For converters, the production of BOPE film is similar to that of BOPP film, and the properties also follow BOPP film.

Normal LDPE film is very stretchy and can not endure the tensile stress on the web during printing, which could distort the color overlapping and information display.

BOPE actually uses high-density polyethylene and makes the molecular orientation in both the machine direction and the transverse direction. BOPE film can work as the outer printing substrate, with great adhesion to inks and high color fidelity when the CMYK colors are used to present complicated figures. Please check attached custom printed custainable LDPE coffee bag for further understanding.

MDO-PE Film

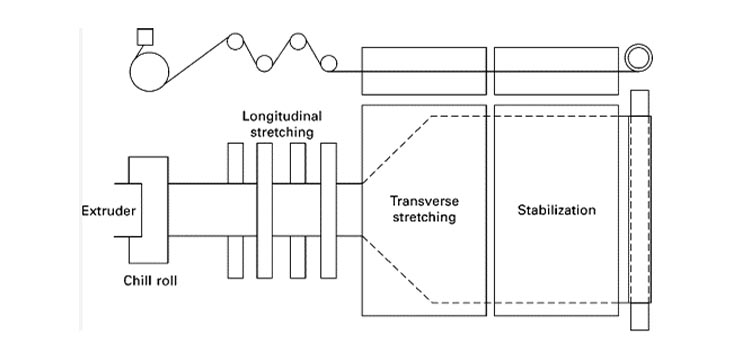

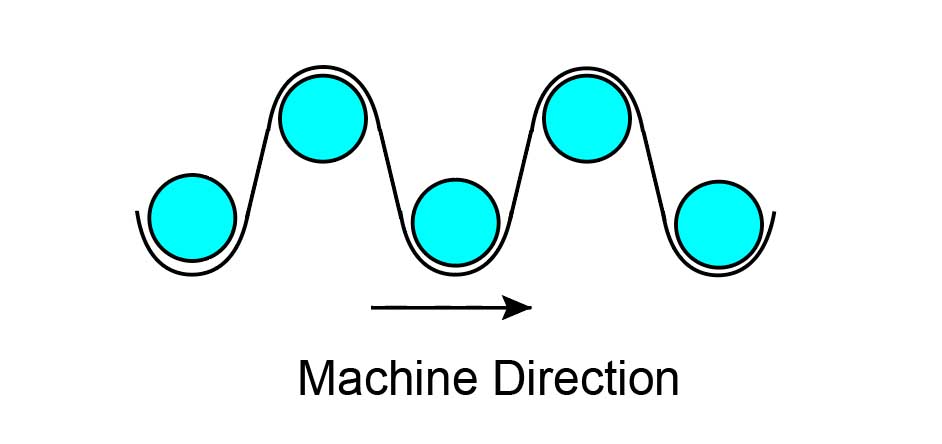

MDO-PE film means machine-direction-oriented polyethylene film. The film forms under a certain blow-inflation ratio when the melted polymer comes out of the extruding die on blown-film machinery. To achieve the machine-direction orientation process, the film has to be heated to a particular temperature, and it will pass through several fast-moving rollers with increasing speed after each other. This action will stretch the film sufficiently in the machine direction. The offline film needs rapid cooling to set itself into its final shape.

The MDO-PE film is of excellent clarity, to present the information clearly when the artwork is printed on the inner side. Here you may have a close understanding of the print effect of this custom print sugar doypack.

HDPE Film

HDPE stands for high-density polyethylene film. This versatile plastic material is known for its high tensile strength, stiffness, adhesiveness, and opacity. Usually, HDPE film is entrapped as the middle supportive and barrier layer in the multilayer flexible pouch to present a stiffer pouch and better self-standing effect.

PVA Coated LDPE Film

PVA, sometimes also called PVOH or PVAl, is short for Polyvinyl alcohol. It is an eco-friendly, water-soluble synthetic polymer derived from fossil chemicals. Like PVDC coating, a layer of PVA can be applied over the surface of polyethylene film to reduce the permeation rate of oxygen and prevent coffee spoilage in sustainable polyethylene packaging.

EVOH-PE Film

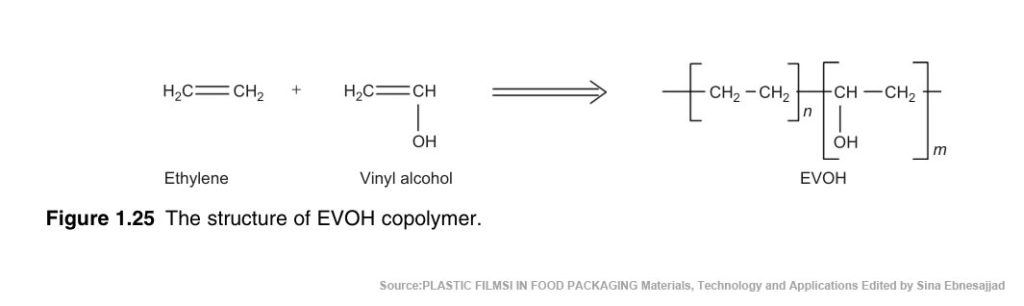

EVOH, short for Ethylene Vinyl Alcohol, is a copolymer of ethylene and vinyl alcohol that is intended to enhance the properties of the film materials in the flexible packaging industry. EVOH polymers provide barrier properties against oxygen, carbon dioxide, nitrogen, and helium and maintain a fine barrier property against moisture over a wide range of applications. The ethylene content affects the oxygen-barrier properties of EVOH in synthetic polymers. Packages containing EVOH resins can effectively retain fragrances and preserve the aroma of the contents within the package. At the same time, undesirable odors are prevented from entering or leaving the package.

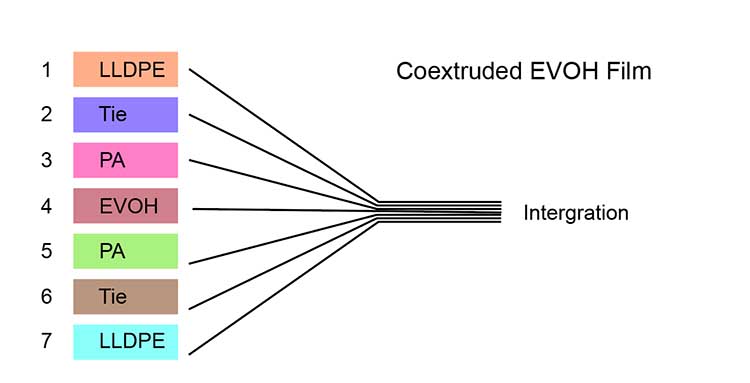

Unfortunately, EVOH can not be produced into film materials alone. It needs to be entrapped within the structure of the film material, as shown in the figure below, to understand the structure of a 7-layer co-extruded EVOH film.

When EVOH-LDPE film is finished, it mimics the appearance of traditional LDPE film, and most people may not be able to distinguish it from the normal one.

LDPE Film

LDPE, which stands for low-density polyethylene, is a thermoplastic polymer that is a member of the polyethylene family. It is known for its flexibility, toughness, transparency, and corrosion resistance. Based on its versatility, LDPE film is so widely used in the flexible packaging field, and forms the most fundamental part of sustainable PE coffee packaging.

LLDPE Film

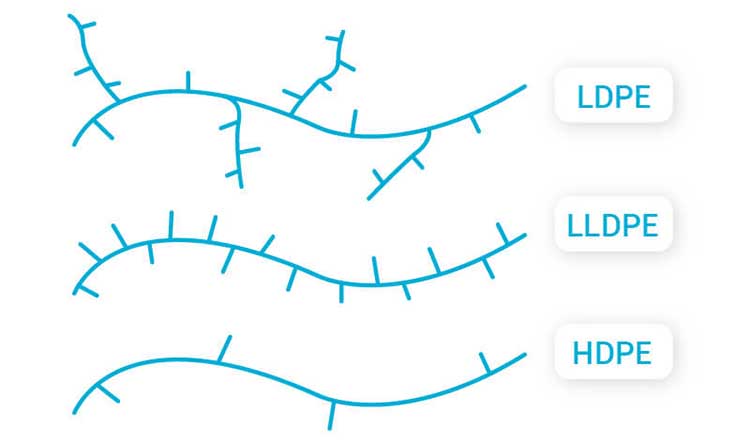

Compared with LDPE film, there are fewer and shorter branches on the main chain of the polymer molecule. Branching affects the crystallinity. A high degree of branching would reduce the size of the crystalline regions, resulting in lower crystallinity. Therefore, LLDPE film is finalized with increased strength, improved puncture resistance, and enhanced sealing properties.

Casted LDPE Film

Casted polyethylene film is a high-strength, highly transparent plastic film made through the cast extrusion process. Compared to blown LDPE film, cast LDPE film offers better uniformity, a lower initial sealing temperature, and higher clarity, which enables the finished foil laminate to run more smoothly in the form-fill-seal lines.

Commercial Sustainable Polyethylene Foil Laminates

The various polyethylene films must be integrated to meet the stringent requirements of sustainable coffee packaging, such as good protection, preserving aroma, reducing oxygen permeation, and offering great custom printing options. Some foil laminates are produced in our manufacturing plant for preserving roasted coffee, with values of moisture vapor transmission rate and oxygen transmission rate listed in the table below.

| PE Foil Laminates | WVTR @38℃, 90% RH cc/m2/24hr ASTM E 96 | OTR @23℃, 0% RH cc/m2/24hr ASTM D 3985 |

| BOPE/APE | 3.2 | 2.0 |

| BOPE/HDPE/APE70 | 0.7 | 1.2 |

| MDOPE/MDOPE/EVOH-LDPE | 1.2 | 1.8 |

| MDOPE25/HDPE30///APE70 | 1.0 | 1.7 |

| MDOPE25/AVMDOPE25/LDPE70 | 1.6 | 0.7 |

| MDOPE25/BOPE25/APE70 | 2.7 | 1.4 |

Are barrier properties enough for roasted coffee?

For traditional barrier film materials, aluminum foil, metallized film, and ceramic films are among the top three films used for roasted coffee packaging. The WVTR (water vapor transmission rate) and OTR (oxygen transmission rate) values of three common foil laminates are listed in the table below, with tests conducted using a Mocon permeation tester in our laboratory.

| PE Foil Laminates | WVTR @38℃, 90% RH cc/m2/24hr ASTM E 96 | OTR @23℃, 0% RH cc/m2/24hr ASTM D 3985 |

| PET12/AL7/LDPE100 | 0.01 | 0.01 |

| PET12/VMPET12/LDPE100 | 1.05 | 0.95 |

| PET12/AlOx-PET12/LDPE100 | 0.8 | 0.9 |

As we can see from the two tables above, the barrier properties of the sustainable polyethylene foil laminate are comparable to those of metallized foil laminate or AlOx-PET foil laminates, which are sufficient to preserve the coffee in freshness and aroma for a qualified shelf life. As we know, the film materials of Nescafe 15 gr stick packages in China market is PET12/VMPET12/LDPE, with an overall thickness 80~100 microns.

Therefore, specialty coffee roasters can establish a strong foothold in sustainable polyethylene packaging for distributing their coffee, thereby building a more sustainable profile for their branding and activities, which is more favorable in the current market. Of course, if you aim to provide the very best flavors in your coffee products, please stick to aluminum foil laminates. There is no sustainable foil laminate that offers a comparable preservation of fragrance and aroma to aluminum foil laminate.

At Tongli Packaging, we offer various sustainable polyethylene coffee packaging that can be fully recycled and re-produced into other plastic products. The custom artwork can be printed using gravure printing, flexographic printing, and digital printing in our manufacturing plant, resulting in a refined print effect on the finished coffee bags. You can contact our professional team for further assistance if you have any questions about coffee packaging.