Description

1 Introduce

This high quality stand up quad seal packaging is carefully crafted by a company specializing in packaging solutions. This type of packaging can well demonstrate the special quality packaging of the liquid and play a great role in storage, transportation, and sales.

Here let us further understand this God’s late packaging bag also hope to be able to provide some help for liquid packaging.

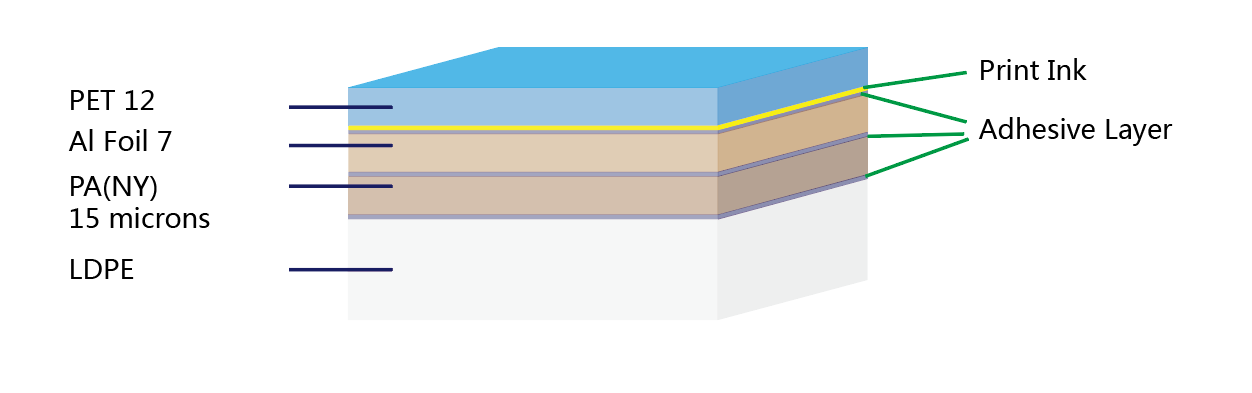

2 Foil Materials

This foil material has a reinforced structure and excellent performance. The foil structure is PET/VMPET/LDPE as shown below.

Next, let’s further understand the structure of this packaging material.

PET is very outstanding in the liquid packaging industry because it has good barrier and stretch properties and can display various important information, such as the shelf life of the product and the population it is suitable for. The market demand for food and pharmaceutical packaging is also huge.

VMPET, also known as vacuum aluminum-plated polyester film, is a thin layer of aluminum atoms deposited onto the surface of PET (polyester) film substrate under vacuum conditions to form a bright metal film, which is widely used in packaging.

LDPE, or low-density polyethylene, is a thermoplastic polymer that is a member of the polyethylene family of plastics. Its advantages are toughness, flexibility, corrosion resistance, and light and easy plastic chemical resistance and impact resistance. It can increase the tightness of liquid and store liquid better.

3 Properties and Quality Assurance

3.1 Exquisite print quality

318ml spout cheer pack for hydrogen rich water9-min

Our crafts are completed with rotogravure printing machines, which can print up to 10 colors. We meet the needs of our customers through excellent technology and craftsmanship.

a. Color Analyzer

color-analyzer-checking

This color analyzer is one of the auxiliary tools in our system to achieve the highest standard for color fidelity. The eXact Advanced doesn’t just validate the color of CMYK and spot color inks, it can simultaneously measure four M modes to visualize the spectral reflectance of a substrate or ink, measure the concentration of a specific ink, and measure the difference of a substrate or ink over white and over black.

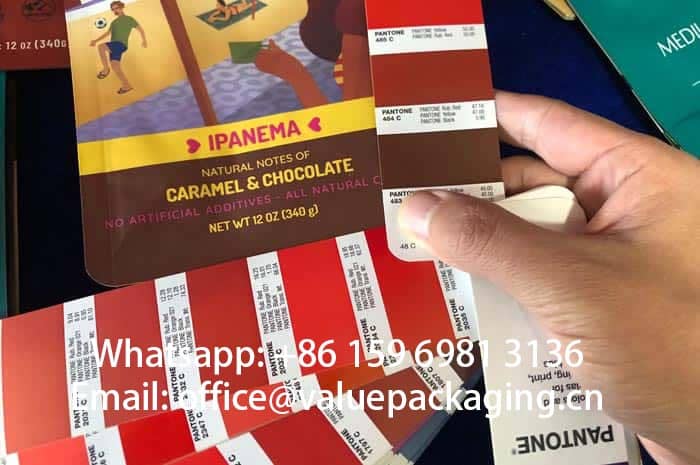

b. Pantone Color Code

Pantone-color-print-examine-coffee-bag

Pantone color guide would be so helpful to locate a specific color for the pring service supplier and the customers, especially there is a large area printed in single Pantone color. For many Pantone colors, the accurateness may be influenced by the printer, paper substrate and environmental factors when it is printed onto physical photo paper. We will locate the Pantone Color Code with the customers in their artwork design before the order is put into produce.

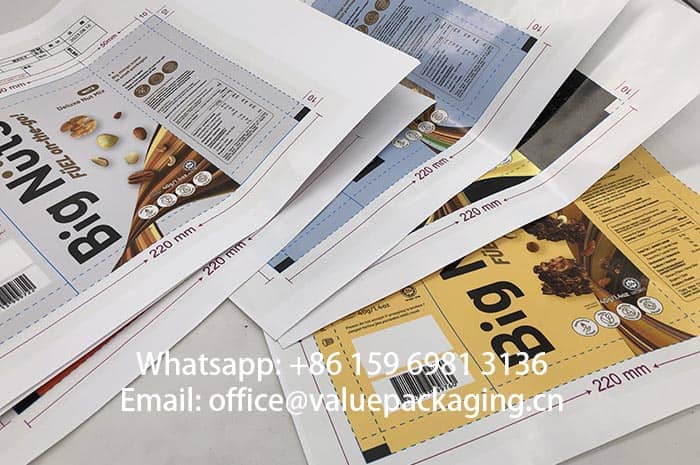

c. Physical Printed On Photo Paper

Print-proofs-printed-on-photopaper

The computer files, such as JPG, PDF, PSD, AI, etc, can not be taken as the guide to determine the color in print production, as they present the colors through electronic screening devices. And different electronic screens may be set in different parameters by the various manufacturers, which will inevitably interfere with the colore presentation. Artwork can only be a reliable guide when printed on physical substrate, with the most common photo paper applied.

You may read here to understand more about how our company ensures color fidelity and consistency for all our orders.

Measures taken to achieve high color fidelity and consistency in reprints

3.2 Dimensional Stability

318ml spout cheer pack for hydrogen rich water5-min

As production and packaging companies adopt high-speed filling lines to improve production efficiency .The dimensional stability of the package is becoming more and more demanding. We have a good understanding of this, and

We are working to narrow the dimensional tolerances for each order we supply in the long run.

3.3 Good standing effect And Stable

318ml spout cheer pack for hydrogen rich water5-min

This four-side sealed bag allows the product to stand better on the shelf, making the product more solid.

3.4 Convenient Nozzle And Anti-theft Buckle

318ml spout cheer pack for hydrogen rich water3-min

The nozzle design allows the four-sided packaging bag to be easily opened and closed, which can maintain the integrity of the packaging. At the same time, this design also plays a role in protecting the liquid cleanliness. You can see that the nozzle is embedded in the bag in a gorgeous way, which can give users a better experience.The anti-theft buckle can better protect the use of the product.

3.5 High Barrier Performance

As explained previously, this foil laminate is finalized with a layer of thin aluminum metal sheet, which is of the best barrier performance against oxygen and moisture vapor. Usually, the roasted beans should be well protected to keep the original flavor and fragrance for a prolonged period, to enable the beans enjoyed by the end consumers.

3.6 Great Mechanical Strength

This reinforced laminated foil can greatly protect cat food ranging from 100g to 120g volume.

We perform various inspections and tests to check the mechanical strength of the finished pouch, like drop tests, hard sudden strikes, anti-pressure tests

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, on customer requirements, and you may check the exact values of this foil material PA15/VMPET12/LDPE in the Technical Date Sheet part of this post.

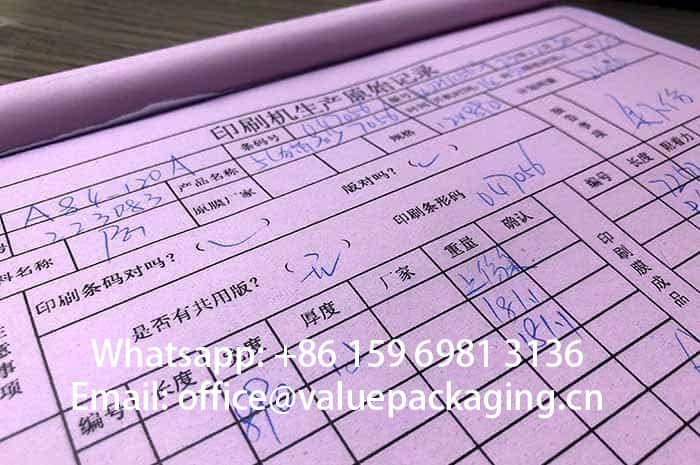

4.1 Manufacturing Traceback

Our manufacturing plant adopts strict quality control measures to ensure every order. Single can meet the requirements of specific customers. With more than ten years of experience in this field. We finalized this QC manual standard to ensure that every order is followed. Follow the correct procedure. Please allow us to guide you to learn more about our QC system.

4.2 Manufacturing Traceback

We use a strict recording system to record production details, such as environmental conditions, process parameters, production equipment, etc

Conditions, etc., which allow us to trace back when something goes wrong.

4.3 QC Test Report Against Each Order

QC test report will be issued for each production order, and the core products will be evaluated. Have to the customer’s high appreciation. You can read the QC test report for 250g and 1000g coffee bag orders here.

4.4 Print Inspection

At our manufacturing plant, print checks are always carried out in a serious way, as we always are. Will not allow a client’s artwork to be realized in a way that deteriorates their business. In our gravure printing. On the brush machine, there is an online inspection system that can eliminate more than 98% of insects in the printing process. You can see how it works on our control panel.

There is also supplementary off-line inspection equipment, to allow us to do the print inspection again whenever it seems necessary.

Perform an airtightness test on each order. The finished coffee bag should be completely sealed so that the product is protected from oxygen and moisture in the environment. We’ll use the equipment below.

4.5 Airtight Property Test

The finished coffee bag should be completely airtight, to get the products well-protected from oxygen and moisture in the environment. We perform the airtight property test against each order with the device as below.

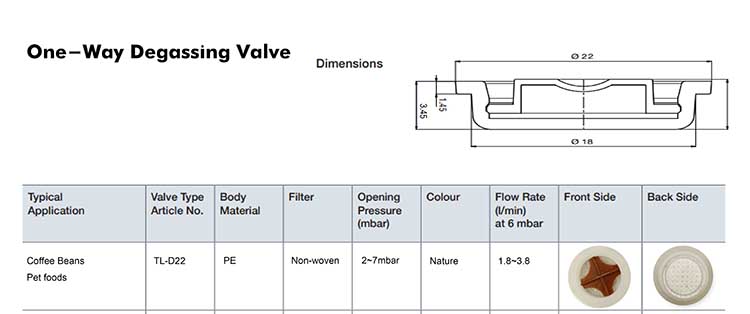

4.6 Gas Release Property Test

The gas will be released from the inside when the air pressure for the inside is 2~7 mbar than the outside environment. Usually, we will immerse the valve welded bag under the water, and check if the degassing valve works well.

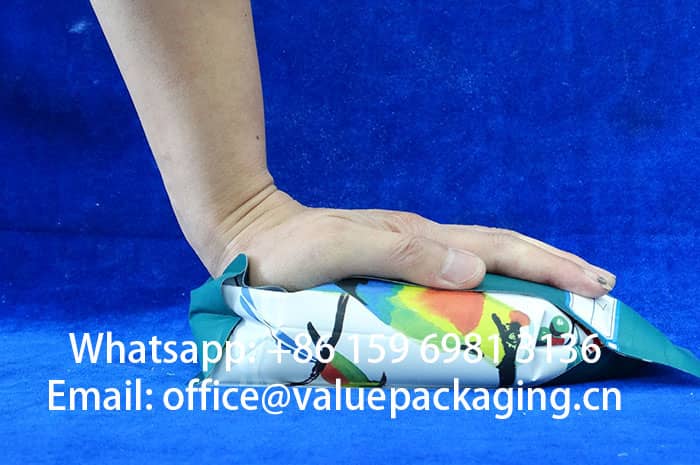

4.7 Drop Test

Drop test should be considered as a very reliable way to check if the coffee bag strength is enough to meet the various conditions, as it copies the way when the products falls off the good shelves, and the finished bag will suffer great sudden shock. In our daily QC work, w. perform drop test against each order, of course, the standard for this drop test should be decided against customer needs.

Here, we are going to drop the filled coffee bag from 1.6m high, for 5 times.

Drop-of-spout-doypack-horizontally

4.8 Hard Sudden Strikes on inflated coffee bags

Hard sudden strikes should be taken as a more fierce test method than drop test, as it causes much higher force on inflated packages.

4.9 Anti-Pressure Test

Pressure testing is another effective way to determine whether the final packaging can make a big difference to the product

Protection, especially for liquid products such as household detergents and windshield washer fluids. For coffee bags, We will carry out the pressure test in the daily QC work to ensure that every order is a great machineGun strength complete.

Coffee bag leakage or damage, whether it is for the distributor or for the manufacturer, is definitely disaster. We never thought this would happen to our client’s business.

Sometimes, for easy and quick operation, we may have a person standing well sealed and inflated. On the coffee bag, check for any burst.

5 Human Food Safety

All the film materials, inks, adhesives, and solvents used to convert into kinds of food bags and packaging materials will comply with the regulations for human food safety. The below graphic shows the mass spectra in migration tests on these multilayer flexible pouches these are in direct contact with foods.

mass-spectra-in-migration-test-for-flexible-multilayer-bag

Through the below link, you will be able to study the certificates on each of the materials adapted in our factory.

6 Dieline of spout cheer pack for 318ml hydrogen rich water

The package dimension should be seriously considered and tested before it is put into order production. You may just reach us for assistance if you need any help.

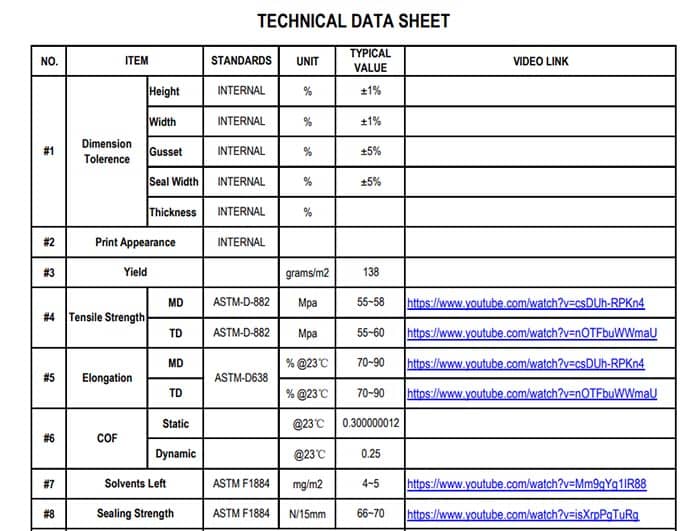

7 Technical Data Sheet of Spout Pouch of Water

Laboratory-test-flexible-roll-foil

Here, we include the specifications on some main items of this multilayer water bag, with the videos showing the test progress in the later columns.

technical-data-specification-sheet-with-test-videos

You may check attached PDF file for a further knowledge on the specifications of this 12oz aluminum foil coffee bag.

Some main items are listed below.

- Dimension Tolerance

- Print Appearance

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

Just reach us if you have any questions with any of the items.

8 More Sustainable Options

With the increasing burden on plastic pollution, more and more manufacturers are now seeking more sustainable packages, like compostable film materials, recyclable mono materials packages, and plant-based materials packages. They all prove to be more eco-friendly and sustainable than the traditional plastic films which are usually derived from fossil chemicals, and very difficult to recycle and break down in the environment.

Here, we are going to share some of the trending sustainable packages for the juice market.

8.1 Compostable film material packages

Thanks to the fast development of plant-based film materials, we can present the multi-layer standup pouch and roll foils in full compostable and biodegradable options.

The compostable substrate films we adapt to convert the multi-layer flexible pouches are listed below.

- BOPLA Film

- PLA+PBAT Film

- Kraft Paper

- Metallized Paper

- Cellulose Film

- Metallized Cellulose Paper

- PBS Film

- PVDC Coated Cellulose Film

- Metallized BOPLA Membrane

We are now achieving multilayer compostable foil materials based on extrusion coating lamination, solvent-free lamination and dry lamination, and then convert into various types of flexible pouches against customers’ requirements.

Some of the common compostable foil structures are listed below.

- Kraft Paper/PLA+PBAT Membrane

- Kraft Paper/BOPLA Membrane

- Cellulose/PLA+PBAT Membrane

- Kraft Paper/PBS Foil Membrane

- Metallized Paper/PLA+PBAT Membrane

- BOPLA/PLA+PBAT Membrane

- Cellulose/Metallized Cellulose/PLA+PBAT Membrane

- Kraft Paper/Metallized Cellulose/PLA+PBAT Membrane

- Cellulose/Metallized Paper/PLA+PBAT Membrane

- Kraft Paper/Cellulose/PLA+PBAT Membrane

- Kraft Paper/Cellulose/PBS Membrane

- Metallized Paper/Cellulose/PLA+PBAT Membrane

Here, we are going to introduce the main performance of these compostable materials pouches.

a. Compostable

All the film materials we adapt are certificated compostable, under home or industrial conditions, complying with the standards EN 13432 or ASTM 6400.

The films will present different biodegradation behaviors under different conditions, such as industrial composting facilities, home and garden conditions, and nature soil conditions.

In most cases, industrial composting can achieve faster biodegradation of compostable film materials than other composting processes because it provides better conditions.

Coffee-bag-composting-progress-under-home-garden-conditions

Some manufacturers would like to have a better biodegradation behaviors of their own compostable packages under nature soil conditions, as in most cases, the abandoned package may not be recycled into human composting facilities.

soil-biodegradation-test-of-film-materials-Nov-2021

You may read here to have a better understanding of the break-down progress of our compostable foil laminated materials under the nature condition in Qingdao, Shandong, North China conditions.

The biodegrading process of compostable film materials buried in nature soil

b. High-barrier performance pouches

Through vacuum metallization, PVDC coating, and AlOx/SiOx depositing, the compostable films can be achieved with better barrier performance, such as water vapor transmission rate (short as WVTR) and Oxygen Transmission Rate (short as OTR). Later on, we will combine several layers of the barrier film and convert into laminate foil, with an improved barrier property for finished packages.odles, or soup products

In below table, we are going to share some barrier data of the most common foil laminates tested on our Mocon permeation tester.

| Biodegradable Foil Laminate | WVTR (g/m2/24hr) | OTR (cc/m2/24hr) |

| BOPLA40/PLA+PBAT60 | 62.2 | 267 |

| Cellulose30/PLA+PBAT60 | 131.5 | 5.6 |

| Kraft Paper45g /PLA+PBAT60 | 44 | 742 |

| Kraft Paper45g/BOPLA40 | 41 | 380 |

| Metallized Paper69g/PLA+PBAT40 | 27 | 127 |

| Cellulose30/Metallized Cellulose20/PLA+PBAT60 | 23 | 0.16 |

| Cellulose30/Metallized Cellulose20/BOPLA40 | 25 | 0.12 |

| Metallized Paper 69g/Cellulose30/PLA+PBAT60 | 5.6 | 1.12 |

| Kraft45g/Metallized Cellulose20/PLA+PBAT60 | 26 | 0.22 |

| Cellulose30/Kraft45g/PLA+PBAT60 | 19 | 117.2 |

| Cellulose30/Metallized Paper69g/PLA+PBAT60 | 8.9 | 1.1 |

c. Alkaline Resistant

alkaline-test-on-compostable-pouch-with-bleaching-powder

We put a certain amount of bleaching powder into the compostable pouches with various foil structures, and place them in an environment of 40~45 Celsius degree, to accelerate the aging process of the compostable pouches.

The test result proves the compostable pouches will be fine for packing alkaline products, like household detergent powder, and hand wash cubes.

However, it is not ok for household liquid detergent and other liquid cleaning chemicals.

You may watch the video below for further knowledge on it.

d. Frozen Treatment

The compostable pouches can be well intended for frozen treatment for some food products, and the mechanical property of the frozen pouch still works well as good protection for the products during the transportation and distribution process.

e. Vacuum Packages

The compostable pouches can be intended for the vacuum packages for products, like milk powder, nutrition products, etc.

f. Hot Filling up to 100 Celsius Degree

The compostable pouch will be fine for the hot filling process, which may work well for juice products.

g. Microwave Oven Treatment

The compostable doypack can be well intended for microwave oven treatment, such as melting the candle wax, etc.

Please note, there should not be metalized film layer in the compostable pouch when it is intended for this microwave treatment purpose.

You may read here for better understanding on the compostable plant-based film materials packaging.

9. Mono Materials Recyclable Pouch Packages

318ml spout cheer pack for hydrogen rich water2-min

Mono meterials pouch packages are truly recyclable, as they can be easily processed into plastic granules which can be used again for other applications. However, for the traditional multilayer laminates, take PET/LDPE for example, it is difficult to process, as PET and LDPE are quite different materials, and can not be melted under the same conditions. That’s why momo materials pouch packages are becoming so widely popular in the packaging field, and highly reputed in the consumer market.

At present, mono-materials pouches are divided into Polyethylene channels and Polypropylene channels, with polyethylene channels much more popular, as they can be converted into kinds of standup pouch packages with relatively high performance.

Here we list the film materials that can be well intended for mono-materials recyclable pouch packages.

- MDOPE Film

- BOPE Film

- APE Film

- LDPE Film

- LLDPE Film

- CPE Film

- ABOPP Film

- CPP Film

- VMCPP Film

- VMBOPP Film

- EVOH-LDPE Film

- HDPE Film

Various foil laminates can be achieved based on the above film materials with different properties, which are intended to meet the particular requirements for specific products. Some of the common mono-material foil laminates are listed below.

- MDOPE/APE

- MDOPE/LDPE

- MDOPE/EVOH-LDPE

- MDOPE/HDPE/APE

- MDOPE/BOPE/APE

- BOPE/APE

- BOPP/CPP

- BOPP/VMCPP

- ABOPP/VMCPPFrom our experience, mono-materials pouches can be well intended for spices powder products.

You may have a further understanding of the recyclable mono materials and pouches here, and just reach us if you have any questions.

10 About the manufacturer

-

bag-making-department

Qingdao Tongli Packaging has devoted itself to the manufacture of quality juice bags for more than 10 years, with long-term customers around the world. You may just rely on us if you would like to get a sustainable and reliable supply for your juice packages.

Reviews

There are no reviews yet.