Faced with the rapidly increasing burden of plastic pollution on the environment, people are increasingly likely to create a more sustainable, circular economy. In the specialty coffee sector, roasters and brands are seeking to conduct their business more sustainably, as this would help them to stand out from the crowded competition and boost their sales.

Compared to traditional plastic coffee packaging, sustainable coffee packaging will have a much less negative impact on the environment throughout the business activities. As a reliable supplier of sustainable coffee bags, we will give an overall introduction to the available substrate film materials and mostly adapted laminates for sustainable coffee bags.

Kraft Paper

Kraft paper should be considered one of the most sustainable packaging materials. It is recyclable, biodegradable, and home compostable. It can not only compost into nutrients that enrich the earth under natural conditions but also be recycled up to seven times, which is so helpful to creating a lower-cost circular economy in our society.

Based on its superior properties, such as excellent mechanical strength, great stiffness, fine printability, versatility, and mechanical stability, kraft paper can be processed into various packaging types and products. Furthermore, it can be well laminated with other substrate materials, which enables the final packages to meet the particular requirements of roasted coffee.

Printing the logo onto kraft paper is easy and flexible, fulfilling the customer’s concern about order quantity.

Kraft paper has very bad barrier properties against moisture and oxygen, as it is made of porous plant fibre. However, the roasted beans absorb moisture easily and are quite oxygen-sensitive, so some high-barrier paper materials have been developed on kraft paper substrate.

Metallized Kraft Paper

Metallized kraft paper is one of the most commonly used materials in the coffee packaging sector. With a layer of white clay coated on the surface of kraft paper, another aluminum metallized layer can be perfectly achieved over the clay layer. Finally, high barrier performance will be enabled on metallized kraft paper material.

Metallized kraft papers applied in our flexible packaging are tested to be biodegradable under natural conditions. In the flexible packaging area, metallized kraft paper must be lined with an inner sealing layer, such as PLA, PBS, or LDPE, to form a final sustainable package.

Cellulose Film

Cellulose is a polysaccharide found in plant woody parts. It is the main component of plant cell walls and should be the most abundant biopolymer on our planet.

Cellulose is biodegradable, compostable, renewable, and sustainable, which increases its potential use to make sustainable flexible packages for roasted coffee in the future.

Other than the opaque property of kraft paper, cellulose is highly transparent, which enables consumers to see inside products. Furthermore, customer artwork can be printed on the outside or inner side of cellulose substrate for powerful branding.

Made from wood pulp, cellulose film is quite moisture-sensitive, and its properties may decrease significantly when it absorbs enough moisture in the environment. Usually, a layer of PVDC coating is coated on both sides of the cellulose substrate to enhance its resistance to moisture.

The barrier performance of the cellulose film can be reinforced by depositing a thin layer of aluminum atoms onto the surface through vacuum metallization (usually abbreviated as VM in the flexible converting industry). It can also be laminated to other sustainable film materials like aluminum foil, metallized paper, vacuum metallized BOPLA film, etc., for the improved barrier performance required by roasted coffee.

Polyethylene Film

Polyethylene film is considered a sustainable film material for coffee packages mainly due to its fine recyclability. Unlike cellulose film, which degrades quickly, polyethylene film may degrade in hundreds of years in natural conditions, as the energy needed to break down the polymer molecule is much higher. The large polymer may break into tiny microplastics, harming the human food system. So, to achieve a sustainable future for our human beings, better recycling and reproduction of polyethylene should be researched and implemented.

Some branches of polyethylene film are applied in the flexible packaging for roasted coffee, as shown below.

- LDPE film: Low-density polyethylene film

- HDPE Film: High-density polyethylene film

- LLDPE Film: Linear Low-density polyethylene film

- BOPE Film: Biaxially oriented polyethylene film

- MDO-PE Film: Machine direction oriented polyethylene film

- CPE Film: Cast polyethylene film

- APE Film: PVA-coated polyethylene film

- AVMPE Film: PVA-coated vacuum metallized polyethylene film

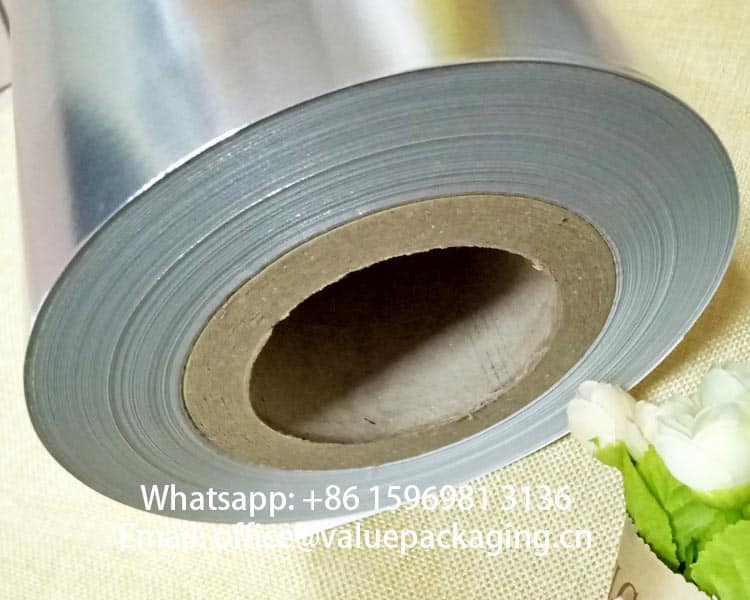

Aluminum Foil

Due to its recyclability, aluminum foil can be considered a sustainable substrate material. Aluminum foils, jars, cans, and other hardware can be well recycled into the production system, and new aluminum foils will be produced. The most commonly used thickness of aluminum foil in the flexible packaging industry is 7 microns, with a well-controlled number of pinholes to ensure the barrier property required for roasted coffee.

BOPLA Film

PLA, short for Polylactic acid, is a biopolymer derived from natural resources like corn starch, cassava starch, sugarcane, etc. BOPLA film is achieved through biaxial orientation craftsmanship, which improves the properties of the final film, like better clarity, uniformity, higher mechanical strength, and printability.

PLA+PBAT Film

PLA+PBAT film is actually a blown film made of PLA and PBAT blends. As the BOPLA film is very tough and rigid and does not have great seal strength, it may not work well as a protection for coffee products when converted into coffee bags.

That’s why the PLA+PBAT blended film is developed.

PLA+PBAT film is biodegradable and industrially compostable (not home and garden compostable). It is soft and able to provide sealing strength similar to that of polyethylene film when the flexible coffee pouch is newly produced. Nowadays, PLA+PBAT film is the most commonly used biodegradable film as an excellent inner sealing layer at the best cost.

Through the video below, you may get a fine understanding of the softer effects of flexible standup pouches achieved by PLA+PBAT film.

PBS Film

PBS is a special candidate for the new development of bio-based food packaging due to its good processability, improved thermal stability, and chemical resistance. Both PBS film and PLA+PBAT film will work as excellent sealing layers in the flexible stand-up coffee pouches.

Moreover, PBS film has better biodegradation performance than PLA film. PBS film will break down into carbon dioxide and water during the activities of microorganisms when buried in soil. So, it can be considered home & garden compostable film material, favored by more and more businesses who want to reduce the impact of their activities on the environment.

However, the cost of PBS film is much higher than that of PLA+PBAT film, which restricts its application in the coffee packaging field.

Okay, here we have listed the sustainable packaging film materials available in the current market for roasted coffee bags. Of course, none of them can be used singly to meet the versatile requirements of roasted coffee. To make real sustainable coffee bags, a two-layer, triplex, or even a 4-layer foil needs to be achieved and then converted to various formats. We will introduce each of the commercial foil laminates and bags in future posts.

At Tongli Packaging, we are dedicated to creating stunning and sustainable coffee bags that meet the stringent requirements in filling, transportation protection, distribution, and branding.

Our compostable coffee bags are certified by Din Certco in complete compliance with the European certification standard (EN 13432). Your logo can be well printed by gravure printing, flexo printing, and digital printing at our manufacturing plant.

For more information on sustainable coffee packaging, you may contact our team.