In the current coffee market, many items are packed in this self-supporting bottom gusseted bag. This brown kraft doypack bag is made of plant-based paper foils and well intended for 200 grams of roasted coffee, as more and more specialty coffee roasters are seeking sustainable packaging for their products and try to build an eco-friendly branding in the impression of their customers.

This coffee doypack bag is provided to our customers anonymously, and provide more flexibility to the customers to apply their labels.

Ok, let’s get into a further explore of the foil materials of 200 grams plant-based paper foil coffee doypack bag.

Packaging Foil Materials

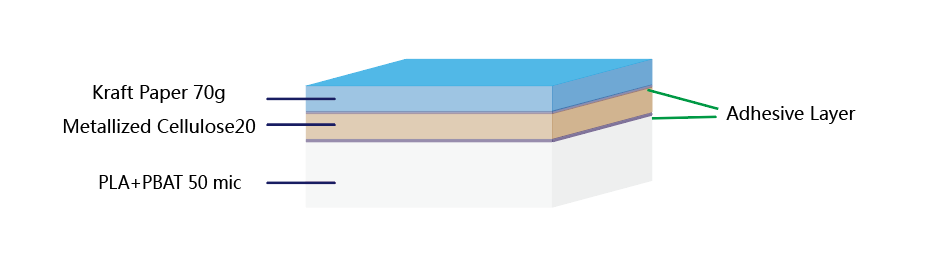

The foil materials of this paper coffee doypack bag is formulated in 3 three layers, with details shown in the figure below.

Usually, we describe the foil materials as Kraft Paper70g/Metallized Cellulose20/PLA+PBAT50. Customers’ artworks can be printed on the surface of the outside kraft paper substrate. Metallized cellulose works as the middle barrier layer, to well preserve the flavor and aroma of the roasted coffee. PLA+PBAT film works inside as sealant layer to finalize the finished package.

Next, let’s get into a deeper understanding of each substrate film material.

Brown Kraft Paper

Kraft paper is one of the most commonly used material to increase the eco-friendly and sustainability for the coffee packages. Due to the versatility, like light weight, heavy-duty, durable, tear-resistant, and low cost, it helps the roasters to create value-added packaging and a powerful marketing for their products.

As kraft paper is made from renewable resources, like plants and wood pulp, it is considered recyclable, renewable, biodegradable and compostable, which strengthens the green effect of the coffee brand.

Metallized Cellulose Film

Cellulose is the most abundant biological polymer on Earth, which makes it low cost and renewable. Metallized cellulose film uses cellulose paper as the substrate, and deposits a thin layer of aluminum atoms on its surface to achieve better barrier properties. It can be used as a reinforcement layer for products that need to isolate moisture, oxygen, grease, etc.

Metallized cellulose film in coffee bean packaging can not only meet the needs of freshness preservation, but also respond to the trend of environmental protection. It is an important development direction in the field of food packaging in the future.

PLA+PBAT Film

The PLA+PBAT film is the most common biodegradable film commercialized in various demanding market, which actually contains PLA (70~85%) blended with polybutylene adipate terephthalate (10~20%) and plasticizer (2~10%). With great mechanical strength, physical stability, great sealing performance and printability, this film is now extending its packaging application for more and more products.

Due to different understanding on this blended film, some people may just call it PLA Film, as actually PLA occupies the largest content of its formulation. Actually, there are two kinds of biopolymer resins in this formulation, with PBAT not able to be neglected, so usually for industries, the professionals will call it PLA+PBAT film, which is able to describe the film in a better understanding.

At present, China’s domestic blow molding production lines can produce PLAT+PBAT films with a thickness of 30 to 150 microns and a maximum roll width of 1,250 mm.

These 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process.

Then, how does this foil laminate perform? Does this bag fulfill the requirements for 200 grams of coffee?

Great Standup Effect

Based on this foil structure Kraft Paper70g/Metallized Cellulose20/PLA+PBAT50, the overall thickness should reach up to 160~170 microns. Moreover, kraft paper is of great stiffness, so the finished bag can present excellent standing effect for 200 grams of coffee.

Some customers may believe this foil bag is too stiff and rigid, and lighter kraft paper, such as 40 gr, 45 gr, 60gr, may be preferred in this laminate.

Great Protection Coffee Bag

The doypack bag will protect the coffee bean product during filling, transit, and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, the doypack package will never be allowed to break. Can you imagine coffee beans scattered all over the ground?

We put the mechanical property of this 200g plant-based paper foil coffee doypack bag on our top priority in our manufacturing plant. Serious measures are taken in our QC system, to assure each order is finalized with the expected result.

Put it simply, we perform drop test on filled package against each order in our plant.

Here, we are going to perform a drop test on 1kg filled bag from a height of 1.6 meters,to see how it performs. The bag did not break after 3 drops. You are advised to watch the video for further understanding.

Aroma Preservation

Preserving freshness and protecting the coffee inside should be the great concern of the roasters. We need to

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The table below shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, PET/LDPE foil laminate will be able to meet most of the requirements for 180-gram corn starch. WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the table below.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 25 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 22 |

Technical Data Sheet of 200 grams coffee doypack pouch

Here, we attach the specification sheet of this 200 grams coffee bean sahcet based on Kraft paper/metallized cellulose/PLA+PBAT.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to get a further understanding of this PET/PA/LDPE laminated foil, you may just read it here.

More Sustainable Materials Options

Fully Recyclable Mono Materials

Some of our customers are actually moving to fully recyclable mono materials bags.

Now it’s the end. You are welcome to reach us when you have any questions regarding coffee bean pouches. Have a nice day.