This is a Pillow Pouch, and people may also call it back-sealed pouch.It is a large part of the packs for powder coffee in the current market.The bag is usually achieved from roll foils on the form-fill-seal machineries with the lowest cost.An imaginative artwork design can be printed on all sides of the back-sealed pouch,And all the information the consumer needs can be printed on it, which makes the final package more attractive to consumers.

We are a professional company specialized in packing and exporting, we are making the best use of the film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We are committed to telling the story behind this Nestle powder coffee drinks bag. In this article, we will introduce the the exact foil materials of this Nestle powder coffee drinks bag.This can help the Nestle powder coffee be liked by the majority of users, so as to seize more market share.

We can get a good idea of the above picture from the above picture. It is an opaque pouch with a delicate pattern on the outside, and it can hold 15 grams of powder coffee with an excellent filled level.The overall thickness of this PET12/AL/LDPE laminated foil around 74.5 microns. You can see that the thickness of this finished powder coffee bag is around 145 microns in the picture below.

Ok, let’s get into the details of this Pillow Pouch.

Packaging Foil Materials

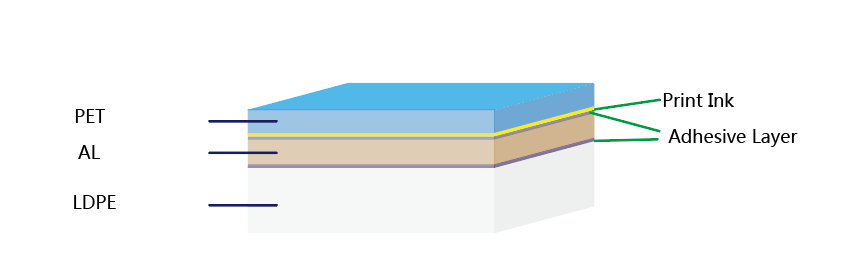

The figure below shows the composition structure of this laminated foil material which is used to convert this Nestle powder coffee drinks bag.

This foil laminate shows the typical structure of a multilayer foil, with clear polyester film 12 microns (equals to 0.48 gauge) working as outside print substrate, aluminum foil 7 microns working as middle barrier and supportive layer, LDPE film works as the inner sealing layer, which can be modified to meet the requirements of various products.

Next, let’s get into a deeper understanding on each substrate film materials.

PET Film

PET film, sometimes BOPET film, is one of the most commonly used print substrates in flexible packaging area. It is of great printability, mechanical strength, processing stability, high temperature resistance and grease resistance.It is a versatile material with many uses due to its physical, mechanical, optical, thermal, electrical, and chemical properties. PET film is available in various thicknesses, widths, and transparencies.The film has many uses.

AL Film

Aluminum foil is 98.5% aluminum, with the remaining percentage primarily made up of iron and silicon to increase strength and puncture resistance. It has many properties, including: Durability, Non-toxicity, Oil-proofness, Chemical resistance, and Good thermal conductivity.

LDPE Film

LDPE, or low-density polyethylene, is a thermoplastic polymer that is a member of the polyethylene family of plastics. It is known for its flexibility, toughness, transparency, and corrosion resistance. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. It is often used for manufacturing plastic goods like cling wrap, juice containers, orthotics, and prosthetics.

LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. It’s also lightweight, corrosion resistant, and has good chemical and impact resistance. LDPE is often used in packaging materials, such as milk pouches and food wrappers, because it’s a good moisture barrier and keeps products fresh.

LDPE is environmentally friendly, low-cost, and low-energy. However, it’s not suited for applications that require stiffness, high temperature resistance, or structural strength. LDPE also has limited resistance to some chemicals.

The customer artwork is printed reversely on the inner side of the first PET film layer in the gravure printing system. Then, these 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process.

Usually, we describe the finished laminate as PET/AL/LDPE foil. So, how does this foil structure perform when it is intended for Nestle powder coffee drinks bag? Will it break during the transit?

Great Flavor Retention

AL has many properties, including: High temperature (up to 121 degrees), low temperature (minus 50 degrees), some food bags used for high temperature cooking can use this material; Good oil resistance and fragrance performance is particularly outstanding; Excellent barrier performance, strong air barrier performance, anti-oxidation, waterproof, moisture-proof; Good heat sealing performance, high flexibility; Food packaging bags made of aluminum foil material to package food non-toxic and tasteless, health and safety in line with national health standards.This characteristic of AL allows it to retain its flavor for a long time.

Mechanical Strength

First,PET is of great printability, mechanical strength, processing stability, high temperature resistance and grease resistance.Second,we put the mechanical property of this 15g Nestle powder coffee drinks sachet on our top priority in our manufacturing plant. Serious measures are taken in our QC system, to assure each order is finalized with the expected result.

To put it simple, drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces.

Barrier Performance

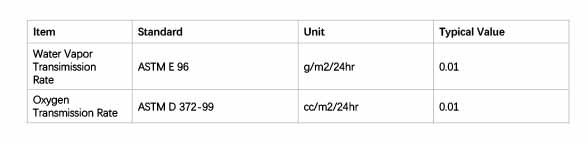

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The product will be kept away from these two elements to stay fresh as long as possible. However, please keep in mind that, the barrier property of this laminated foil is just a part of the measures taken to ensure the shelf life of powder coffee products. The below table shows the typical value of the WVTR and OTR of this triplex foil laminate PET/AL/LDPE.

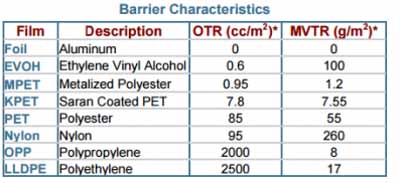

This foil laminate has excellent barrier performance, It is easy for the customers to understand.Through the below table, you can easily find out the typical values of moisture vapor transmission rate and oxygen transmission rate of common substrate film materials.

So, some reinforced foil structures are better protections for the freshness and flavors of powder coffee products, with some available items listed as below.

You may reach us for further ideas on each foil structure if you need any assistance.

Technical Data Sheet of 15 grams Nestle powder coffee drinks bag

Here, we attach the specification sheet of this 15 grams Nestle powder coffee drinks sachet based on foil laminate PET/AL/LDPE.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

You are welcome to ask us for some specific information about this Nestle powder coffee drinks bag.Have a nice day.