In daily life, we often come across various kinds of food in small packages, such as this 30-gram package of cumin granules flat zipper lock bag. Every time we use it, we may inadvertently notice its bag. Some bags seem to be very tough, while others are relatively soft. These differences make us wonder what materials these cumin bags are made of. And what kind of impact does this material have on the preservation of cumin and our use?

flat zipper bags are very popular in the cumin market.With a flexible combination of various fossil chemical and plant-based film materials , they shield cumin from moisture and oxygen in transit, outperforming bottles and jars in cost. PET/LDPE is popular due to price. The bag’s sides bear creative artworks, meeting branding and sales demands.

As a well-known flexible packaging manufacturer located in Qingdao, China, we are making the best use of the packaging film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We focus on making flat zipper lock bag pouch with story-telling features for cumin food. These bags can boost product sales and build a good brand image. In this post, we’ll analyze the specific foil materials of the 30 grams cumin granules flat zipper lock bag packaging, hoping it can be a reference for your products.

Now, let’s get into the details of this 30 grams cumin granules flat zipper lock bag packaging film material.

Packaging Foil Materials

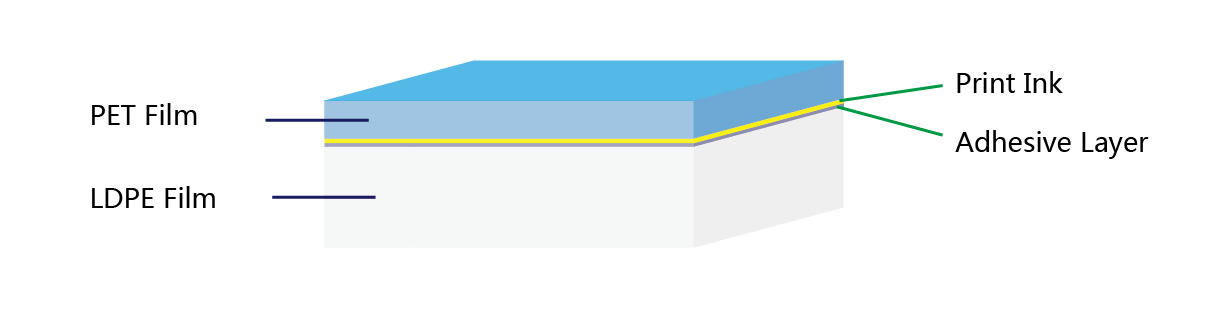

This foil material is a reinforced structure with excellent properties for cumin packages. The foil structure is PET/LDPE, with a graphic as below.

The film material of the cumin package is made of two layers. The printing layer is PET film, and the LDPE film works as the inner sealing layer. The thickness of the LDPE film should be adjusted to suit the requirements of the 30 grams cumin granules flat zipper lock pouch.

Next, we will have a more in-depth discussion about each substrate film material.

PET Film

PET film, sometimes BOPET film, is one of the most commonly used print substrates in flexible packaging areas. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality, and also provide great mechanical strength to the final package.

LDPE Film

LDPE means low-density polyethylene film, which is the most used inner sealing layer for seasoning bags. It can provide enough sealing strength and airtight properties for the final packages. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. Most importantly, LDPE membrane can be modified against the requirement of specific products, and finalize the package with great seal strength and protection. The thickness of the LDPE membrane film will be decided against the particular application.

In the gravure printing system, the customer’s artwork is printed in reverse on the inner side of the first PET film layer. Through the dry lamination or solvent-free lamination process, these two layers are combined to form a completed laminated foil material. Typically, this finished laminate is referred to as PET/LDPE foil.

Thickness

As you can see from the below picture, the overall thickness of this spout pouch is 0.199 mm, which equals to 100 microns for this laminated foil.

So, how does this foil structure perform when it is intended for corn starch bags? Will it break during the transit?

Mechanical Property

The PET/LDPE composite packaging bag exhibits excellent tensile strength. The PET layer offers a high tensile strength and modulus, ensuring that the bag is highly resistant to tearing when subjected to a certain amount of tensile force. For instance, during the handling of bags filled with heavy objects, the PET layer can effectively endure the tension resulting from the item’s weight, thereby averting any tearing on the handle or other stress-prone areas of the bag.

The LDPE layer has lower tensile strength than the PET layer, but its presence increases the overall flexibility of the bag. This means that when subjected to a small tensile force, the bag can have a certain degree of tensile deformation without breaking immediately so that the bag can adapt to a certain range of external force changes

In our manufacturing plant, the mechanical property of the 30-gram cumin granules flat zipper lock pouch is given the highest priority. Stringent measures are implemented within our QC system to ensure that each order is completed as anticipated.

To put it simply, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces.

Sure, there are reinforced foil structures available for more robust packages.

- PET/AL/LDPE

- EVOH/LDPE

- PET/ VMPET/LDPE

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, PET/LDPE foil laminate will be able to meet most of the requirements for 30-gram cumin granules flat zipper lock pouch. WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the table below.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.85 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.2 |

Technical Data Sheet of 30 grams cumin granules flat zipper lock pouch

Here, we attach the specification sheet of this 30-gram cumin granules flat zipper lock pouch based on foil laminate PET/LDPE.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

Learn more about this foil laminate on our company website.

More Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages which leads to a more eco-friendly activity of the business. Upon the recent investigation of the nut market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Compostable Packaging Materials

The compostable packages are based on plant-based fibers like cellulose, or bio-mass like corn starch, cassava, or sugarcane. The resins derived from these resources are usually named bio-polymer, which can break down into inorganic elements under the functions of algae, bacteria, and other microorganisms.

At present, we have developed several compostable foil materials that can be intended for powder food, as shown in the list below.

- Metallized Paper/Cellulose/VMPET/PLA+PBAT Film

- Kraft Paper/Metallized Cellulose/PLA+PBAT Film

Fully Recyclable Mono Materials

Fully recyclable materials sachets and rolls are now widely available in the market for packaging lightweight products. They are much cheaper than the high-cost compostable foil materials. Mono materials packages have each layer of the multi-layer foil made of the same resin. This allows them to be easily processed in the human recycling system and then reused for other purposes. As a result, these recyclable materials sachets significantly cut down the percentage of plastic polymer film packages that are disposed of in landfills.

At present, we have developed a number of bags which are constructed with single resin film materials. These bags have proven to be well-suited for the packaging of roasted cumin product. We will provide a more detailed and in-depth analysis in the upcoming posts.

That’s about it for the moment. Should you have any inquiries, don’t hesitate to get in touch with us. Have a great time!