Standing pouch is a large part of walnut kernel packaging in the current market. The foil materials of this standing pouch will have to be a flexible combination of biodegradable or biopolymer film materials, and it should protect walnut kernel from moisture, oil, and oxygen during transportation and distribution.

This biodegradable standup pouch is produced for a well-known domestic brand, which makes a great success in the market. As of lower cost, kraft paper is adopted into this foil material. In addition, all the sides of the standing bag will be printed with creative artwork to attract new customers, and boost the sale.

Located in Qingdao, China, we are a well-known flexible converter that uses the best film materials available on the market, which are stated below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We are committed to creating standing bags that tell stories and increase walnut sales. In this article, we will analyze the exact foil material of this 500g walnut standing bag, and hope it helps for the customers.

Laminated Foil Materials

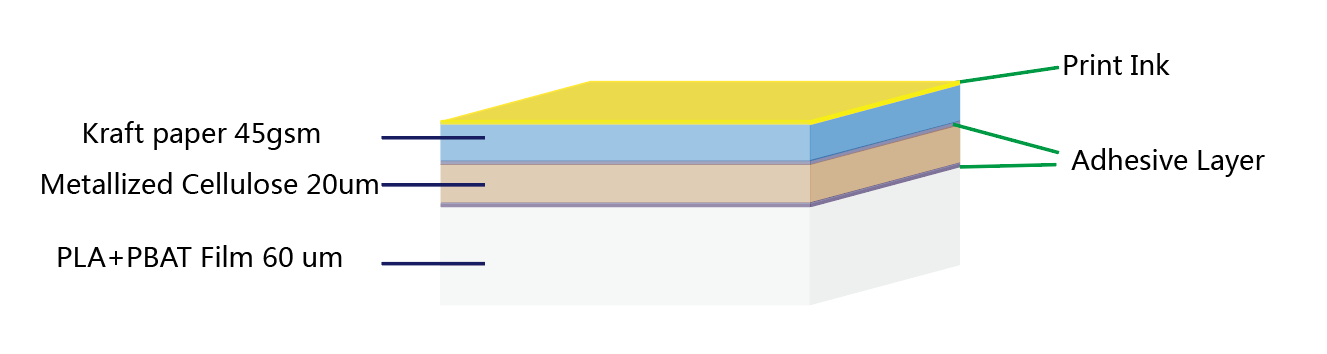

The structure of this biodegradable standup pouch is Kraft Paper/Metallized Cellulose/PLA+PBAT, as shown in the following diagram. It should be considered as a reinforced materials in the barrier properties.

- Kraft paper, in brown color, with weight 45 grams per square meter, works on the outside layer, as a print substrate.

- Metallized Celluloce, with thickness 20 microns, works as the main blocking layer.

- PLA+PBAT film, with thickness 60 microns, works as the inner sealing layer.

then, let’s get a better understanding of each biodegradable film material.

Kraft Paper

Kraft paper is one of the most common paper materials applied in flexible packaging, which finds applications for various products. It is biodegradable, compostable and fully recyclable. Along with the increasing demand for more sustainable packages, kraft paper becomes more and more important in the package areas. When laminated with other bioplastic film materials, the performance can be reinforced to meet the requirements of various products.

Metallized Cellulose

Metalized cellulose is a material that has a thin aluminum layer (usually aluminum) coated on cellulose through special processes. It combines the features of cellulose and aluminum, with good barrier properties against oxygen and moisture. It’s often used in food packaging and has a metallic luster for an attractive look.

PLA+PBAT Film

PLA+PBAT film, is a blown film from the mixes of PLA and PBAT resin certificated by ASTM

6400 standard to be compostable materials. PLA is short for poly-lactic acid, which is

a thermoplastic monomer derived from renewable, organic sources such as corn starch or

sugar cane. PBAT is short for polybutylene adipate terephthalateis, which is biodegradable

random copolymer. This film works as the inner sealing layer for this final stand bag.

Great Standup Effect

When this laminated foil is converted to a standup pouch, eventually it will be able to present excellent standing profile. You may have a deeper study through the below video.

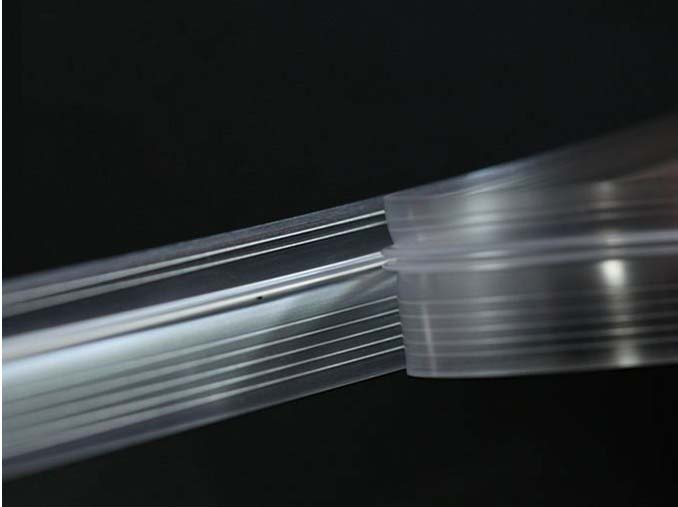

Excellent Airtight Property for Zipperlock

This single-track plastic zipper is applied onto the kraft paper doy pack, with the back and front parts well melted to the inner layer of the doy pack. It enables the package to be repeatedly opened and closed with great airtight properties.

Here, we are going to open and close the zipperlock several times, and check if the air is easy to penetrate into or out of the package. Usually, we will apply a certain pressure on this closed zipper doypack, and check if the inflated doypack is easy to burst.

You are advised to have a further understanding of this test progress through the video below.

Mechanical Property

This reinforced laminated foil is achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, on customer requirements, and you may check the exact values of this foil material in the Technical Date Sheet part of this post.

The above tests are performed against each order, on customer requirements, and you may check the exact values of this foil material in the Technical Date Sheet part of this post.

In our daily QC work, there is a more easy and reliable method to check if the bag strength is enough to meet the various conditions in the operations of filling, transport, loading and unloading, and distribution. We perform a drop test against each order, of course, the standard for this drop test should be decided against customer needs.

Here, we are going to fill 1000 grams of coffee beans into this kraft paper foil pouch, perform drops 5 times, and check if there is any breakage for the package.

Good Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The biodegradable foil materials will have to keep the walnut kernel from the moisture and oxygen contamination.

With the mocon O2/H2O/CO2 permeation tester equipped in our laboratory, we can keep a closer eye on the barrier performance of each laminate foil produced in our manufacturing plant.

WVTR and OTR of this triplex Kraft Paper/Metallized Cellulose/PLA+PBAT foil is listed in the below table.

| Item | Standard | Unit | Value |

| WVTR | ASTM E 96 | g/m2/24hr | 26 |

| OTR | ASTM D 372-99 | cc/m2/24hr | 2.22 |

Actually, there are some measures to enhance the barrier performance, with some items below.

- Kraft Paper/VMPVDC-Cellulose/PLA+PBAT

- PVDC Cellulose/Metallized Paper/PLA+PBAT

Technical Data Sheet of 500 grams walnut kernel standing bag

Here, we attach the specification sheet of this 500 grams walnut kernel sachet based on Kraft Paper/Metallized Cellulose/PLA+PBAT.

More tests are included in this specification sheet with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

More Sustainable Materials Options

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, actually fully recyclable materials sachets and rolls are flooding the market for lightweight product packages in the market at much lower prices. Mono materials packages mean each layer of the multi-layer foil is made of the same resin, which can be easily processed in the human recycling system and reused for other applications. This recyclable materials sachet largely reduces the rate of plastic polymer film packages ending in landfills.

Ok, we come to the end, you may reach us whenever you have any questions. Nice day.