Eco-friendly packaging materials are becoming more and more acceptable by almond roasters, as the pollution of abandoned plastic packages puts a burden on our environment. Of course, people may have different views on the eco-friendly packages. However, kraft paper is considered an outstanding eco-friendly material with affordable cost and superior properties by all.

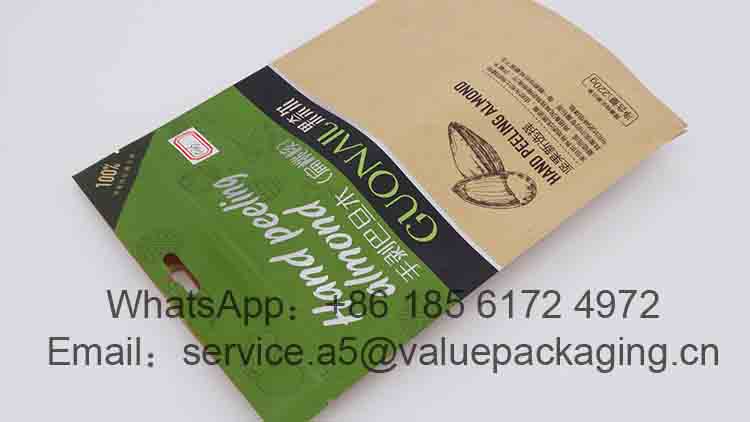

As shown in the above picture, it is a kraft paper bag we are producing for a famous brand in the Chinese market. It helps the customer create a better environmentent-protection profile for their products and finds great success in the market.

In this post, we will analyze the exact film materials of this 220 grams almond paper bag and hope it is of value for you.

Packaging Foil Materials

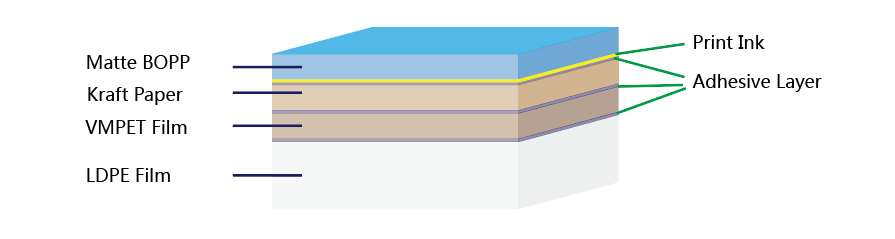

The foil material of this paper bag is Matte BOPP/Kraft Paper/VMPET/LDPE, as shown in the below picture.

- Matte BOPP film, works as the print layer. It can present the delicate artwork in a vivid way.

- Kraft paper ,works as the middle supportive layer, enabling the bag with a better self-standing profile.

- VMPET film ,works the barrier layer. It can provide barrier property for the bag.

- LDPE Film, works as the inner sealing layer.It provides good heat sealing properties

Next, let’s get into a deeper understanding of each substrate film material.

Matte BOPP Film

Matte BOPP, or matte biaxially oriented polypropylene, is a polymer film with a matte finish that absorbs light instead of reflecting it. It needs to be corona-treated before printing, which will increase the surface tension of the film and enhance the adhesion of the ink, making the printed pattern clearer and brighter. At the same time, its matte effect can reduce the reflection and glare of light, making the printed pattern softer and more comfortable, and the visual effect and grade of the bag will be significantly improved, making the product more competitive in the market.

Kraft Paper Film

Kraft paper is one of the most commonly used materials to improve the environmental friendliness and sustainability of pouch. It is also known for its excellent strength and durability. It can withstand greater weight and pressure, making it very suitable for bag-heavy or fragile items. Its tight fiber structure makes the paper difficult to tear or break, thus effectively protecting the contents of the package.

The use of kraft paper in this bag improves the overall texture and appearance of the bag. When consumers see this bag, it will also increase their willingness to buy.

VMPET Film

VMPET film is short for vacuum metalized polyester film, which is achieved under vacuum conditions to deposit a thin layer of aluminum atoms onto the surface of PET (polyester) film substrate and finally realize a bright metallic film that is widely used in flexible packaging and standup pouch packages.

Because of the existence of this film, the pouch’s moisture-proof performance will be enhanced, which is especially important for hand peeling almond that needs to be kept dry. At the same time, it also has excellent gas barrier properties, which can prevent the gas in the package from exchanging with the outside world, ensuring the stability and safety of the packaging contents.

LDPE Film

LDPE film is short for low density polyethylene film, which is the most commonly used inner sealing film for multi-layer flexible packaging in various applications. It is able to provide enough sealing strength and airtight properties for the final packages.

LDPE film has a high cost-effectiveness, and it also has a large elongation and impact strength and excellent softness and toughness, which makes it adaptable to products of various shapes and sizes during the packaging process. When it is necessary to package almond, we also need to consider the moisture resistance and safety of the film used, and LDPE meets these conditions, and it is the best choice as a heat-sealing layer that directly contacts almond.

So, how does this foil perform when it is converted into a standup paper pouch? Will it break in the transit process?

Great Standup Effect

As you can see in the picture below, with the supportive middle layer of Kraft paper/VMPET film, this fourfold foil laminate is stiff enough to create a good standup effect for packages up to 220 grams of almond.

Mechanical Property

In this packaging bag, it is mainly the VMPET layer that provides high tensile strength, excellent impact strength, and puncture resistance. When the package is subjected to large external forces during transportation and storage, the VMPET layer will play a major role in bearing and preventing the film from being overstretched or torn.

We put the mechanical property of this 220 grams almond paper bag on our top priority in our manufacturing plant. Serious measures are taken in our QC system to assure each order is finalized with the expected result.

To put it simple, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces.

Here, we are going to fill 220 grams of almonds into this bag and perform the drop test from 1.6 meters high for 3 times and check if it breaks.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The almond product will be kept away from these two elements to stay fresh as long as possible. However, please keep in mind that the barrier property of this laminated foil is just a part of the measures taken to ensure the shelf life of juice products. The below table shows the typical value of the WVTR and OTR of this foil laminated Matte BOPP/Kraft Paper/VMPET/LDPE.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | ≤4.5 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | ≤1555.52 |

According to the data in the above table, the WVTR and OTR data of the bag are very good, which shows that the barrier performance of the bag is very good, and this is exactly why VMPET plays an obvious barrier role.

In most cases, a layer of vacuum-metallized film, or aluminum foil or clear AlOx Coated polyester film is going to be included in the multi-layer foil materials. Through the below table, you can easily find out the typical values of moisture vapor transmission rate and oxygen transmission rate of common substrate film materials.

Technical Data Sheet of 220g almond paper bag

Here, we attach the specification sheet of this 220g almond doypack based on foil laminate Matte BOPP/Kraft Paper/VMPET/LDPE .

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

More Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages, leading to a more eco-friendly business activity. Upon the recent investigation of the hand peeling almond market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Here, we are going to share some of the trending sustainable packages for the almond market.

Compostable Packaging Materials

The compostable packages are based on plant-based fibers like cellulose or bio-mass like corn starch, cassava, or sugarcane. The resins derived from these resources are usually named bio-polymer, which can break down into inorganic elements under the functions of algae, bacteria, and other microorganisms.

We have developed several compostable foil materials that can be intended for almonds, with the list below.

- Cellulose/Metallized Cellulose/PLA+PBAT Film

- Metallized Paper/Cellulose/VMPET/PLA+PBAT Film

- Kraft Paper/Metallized Cellulose/PLA+PBAT Film

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, fully recyclable material sachets and rolls are flooding the market for lightweight product packages in the market at much lower prices.

Along with the improvement of barrier performance of PE film materials, their foil laminate can be enabled with a fine property to keep the sunflower seeds from moisture. A layer of PVA coating is applied over the surface of LDPE and HDPE film to enhance the moisture barrier. EVOH can be included in the biaxially orientated film, which is usually called BOPE in the flexible packaging industry, to largely improve the oxygen barrier performance.

Nowadays, we have developed some bags based on single resin film materials that are suitable for almond applications. We will provide a further analysis in future posts.

This is the end of our discussion on film materials. If you have any questions, please feel free to contact us, and we will be happy to provide you with a satisfactory solution. Enjoy!