In our daily lives, stand-up pouches account for a large part of the packaging of date products on the market. With a flexible combination of film materials, a self-standing biodegradable pouch for 80-gram dates protects during distribution while being more cost-effective. In addition, its good standing effect can also attract customers.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

The quality of the packaging bag directly affects the product’s market efficiency, so in this article, we analyze the material composition of biodegradable pouch for 80 gram dates.

OK, let’s get into the details of this standup screw cap spout bag.

Packaging Foil Materials

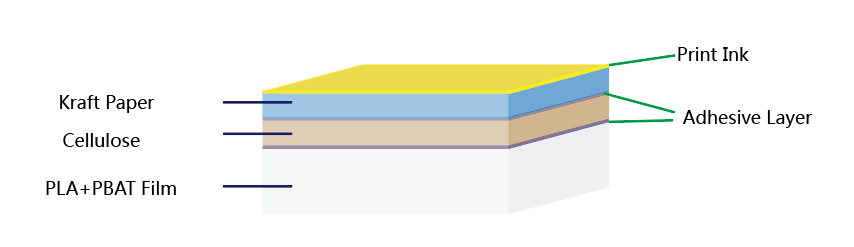

The 80-gram dates stand-up pouch is made of 3 layers. The outer Kraft Paper film is used as the printing substrate film, the Cellulose foil is used as the middle support layer, and finally, the PLA+PBAT film is used as the internal sealing layer.

Next, let’s get into a deeper understanding of each substrate film material.

Kraft Paper Film

Kraft paper is one of the most commonly used materials to increase the eco-friendly and sustainability of packages. Kraft paper is a strong paper made from wood pulp that’s named after the German word kraft, which means “strength”. It’s made using the “Kraft” pulping process, which involves cooking wood chips under pressure to release cellulose and lignin, leaving behind solid wood pulp. The pulp is then shaped, dried, and wound into large rolls that can be cut.

Kraft paper is often associated with brown paper bags or butcher paper, but it can also be white if bleached. It’s stronger than standard cardboard and is often used for packaging because of its strength and durability. Kraft paper can also be used for many other purposes, including:

- Lining particle boards

- As the base paper for sandpaper

- Wrapping flower bouquets

- Electrical insulation in transformers

- Paper sacks for cement, food, chemicals, and consumer goods

- Flour bags

Due to these good properties, Kraft paper films are widely used in packaging.

Cellulose Film

Cellulose paper should be considered as the best biodegradable and compostable substrate film applied in flexible packaging areas. It may fully break down into inorganic materials in 30~90 days in natural conditions

Cellophane has high transparency, good gloss, and a certain degree of strength and toughness. It will not be damaged due to easy stretching in the packaging, ensuring the integrity of the product. It has good barrier properties and can prevent damage to a certain extent. The entry of oxygen slows down the oxidation process of the product and extends the shelf life. Based on these characteristics, cellophane is often used in Ganguo food packaging bags.

PLA+PBAT Film

PLA+PBAT film is a blown film from the mixes of PLA and PBAT resin certificated by ASTM 6400 standard to be compostable materials. PLA is short for poly-lactic acid, which is a thermoplastic monomer derived from renewable, organic sources such as corn starch or sugar cane. PBAT is short for polybutylene adipate terephthalate, which is a biodegradable random copolymer. This film works as an inner sealing layer for this final biodegradable package, with great sealing strength and final fine protection for the products.

The customer artwork is printed reversely on the inner side of the first PLA+PBAT film layer in the gravure printing system. Then, these 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process.

Usually, we describe the finished laminate as Kraft Paper/Cellulose/PLA+PBAT foil. So, how does this foil structure perform when it is intended for standup dates bags? Will it break during the transit?

Great Standup Effect

As the outer layer, Kraft paper provides initial stiffness and strength. Cellulose is located in the middle layer making the product’s standing effect more strong. PLA+PBAT foil, as the inner layer, ensures the sealing property and flexibility of the packaging.

Such a combination of materials pouches have gained popularity due to their eco-friendly nature, functional design, and versatility. They are a sustainable packaging option that addresses consumer demand for more environmentally conscious choices while providing convenience and product protection.

The video below shows well the standup effect of this bottom gusset stand-up white kraft paper bag for dry nuts.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical values of the WVTR and OTR of the most common substrate films in flexible packaging.

The fiber structure of kraft paper is relatively tight and has a certain barrier ability against air and other gases. It can be used for ordinary food packaging that does not have particularly high gas barrier requirements. It can prevent premature oxidation and deterioration of food in certain programs. Cellophane has a very low oxygen permeability and is excellent at blocking oxygen. Based on our experience, Kraft Paper/Cellulose/PLA+PBAT.foil laminate will be able to meet most of the requirements for chili sauce packages.

In the above picture, we are producing for our standup dates bags customers, which is fully opaque and keeps the product in a fine situation even under daylight conditions.

Furthermore, WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the below table.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.01 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 0.01 |

WVTR and VTR Typical Values of Kraft Paper/Cellulose/PLA+PBAT

Additionally, there are a number of other packaging materials you can choose from, and some of the available items are listed below.

- PET/VMPET/LDPE

- Kraft Paper/VMPET/LDPE

- Kraft Paper/VMPET/PLA+PBAT

- BOPA/AL/CPP

We will always come to assist whenever you need help with this product.

Technical Data Sheet of baby jelly screw cap pouch sachet

Here, we attach the specification sheet of the baby jelly screw cap pouch sachet based on film material Kraft Paper/Cellulose/PLA+PBAT.

More tests are included in this specification sheet, with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

Now it’s the end. You are welcome to reach us if you have any questions regarding dates pouches. Have a nice day.