A manufacturer of engine oil located in USA reached us, wondering if we can realize better strength for his spout pouch for engine oil 475ml, as his packis now going through serious break problem in the transporation process. This is very severe problem as the broken package will contaminate other packages, and also cause further pollution to the environment.

When we get the samples from the customer, we perform some essential test to check the performance of the spout bag, and try to find out the true reasons why this package fails.

Drop test

Drop test should be taken as the most reliable method to check if the bag is strong enough. Previously, we perform penetration test on the customer sample bag, and it shows the package is well sealed without any tiny holes.Then we move on to the drop test, and the problem comes clear, the bag just broke on the first drop from 1.5m high, that is really of very bad quality, just watch the video.

There are also some other bad points regarding this package, and you may read here if you want to understand more. (How bad quality is this spout doypack for engine oil).

In this post, we have no intention to share how to realize a better package than this spout pouch, it is our whole job and lots of things will have to be explained if we want to. So in this post, we will just give an overall analysis on how to make a strong package.

How to make a strong package

Film Materials

Film materials comes to the first fundamental part for the strength of this spout pouch. Good film materials will not directly cause the output of good spout pouches, however the bad film materials is surely the first step for the bad spout pouches. In china market, there are recycled film materials, and some factories may put it into re-use in flexible packaging, such as the PET base film after heat transfer process, some second quality PA film imported from foreign countries. Nevertheless, it causes the obvious drop in the cost, however it should be not the option for good quality pouches, actually it is legally banned from the use into food packaging.

All of our materials used are top quality intended for human food grade, you may read more.

Foil Structure

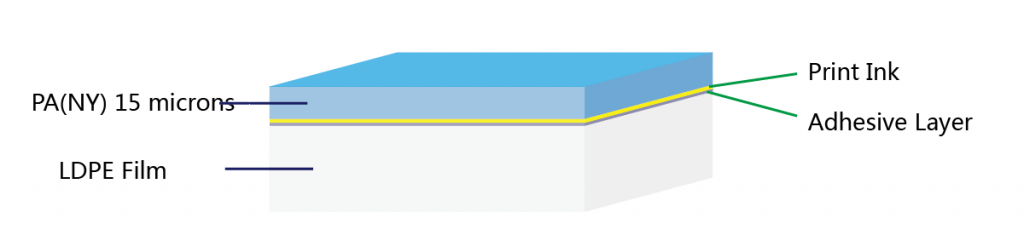

The foil structure for this engine oil spout pouch is PA/LDPE film, as below graphic.

Importantly, the inner LDPE film will have to be modified against the engine oil, otherwise, the engine oil may penetrate through the LDPE film, and cause further delamination problem for the foil laminate.

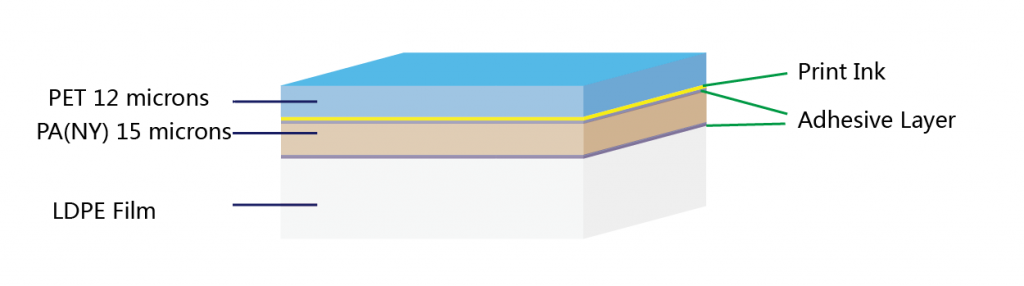

Actually, if the customer would like to get excellent quality for the spout pouch, we advise the customer to choose PET/PA/LDPE 3 layers foil structure, as below.

In this foil laminate, the PET film works as outside print substrate film, and PA film will work as reinforced layer and middle barrier layer against the engine oil, that will make a more robust package for engine oil products.

Solvents in print process sufficiently dried

Solvents,in our factory, ethyl acetate, will be needed in the print process. If the solvents in the ink leveling will not be dried sufficiently, then the solvents in the ink layer will cause not so good bonding strength when it is further laminated with inner layer.

This will require certain measures be taken to ensure the sufficient drying, and you may read more here for further understanding.

Adhesive and lamination process

The adhesive we choose for the lamination process is polyurethane system, with many varities in actual application, the adhesive will have to be seriously evaluated to meet the requirements of engine oil penetration problem.

When it comes to laminatioin process, there should be a set of serious measures taken to ensure enough bonding strength. Can you ever imagine there are many cases in reality that, the coating amount of adhesive is much less than expected, that cause the bonding strength very low in the final foil laminate.so there should be serious measures taken to fight against this sub-standard, we will introduce more on our QC work on the adhesive laminate process.

Bag-making process

When the foil laminate is realized in expected quality for the forming of standup pouches, then the bag-making process should be oligated to finalize the expected pouch.

You can observe from the below picture that the gusseted pleat broke after the drop test, and there is a significance that the sealing of the pleast may exist some problem in bag-making problem.

It is difficult to explain all the measures we take under the bag making process in just a post, you can watch the video below to understand some of the QC work we perform to ensure qualified pouches.

In our opinion, lots of parameters should be strengthened and put into effective execution and supervision, as if the heat temperature is unstable, that will cause the sealing performance of the spout pouch unsustainable, of course, it may lead to easy breakage when the engine oil filled into the pouch package.

Spout welding process

You can observe from the below picture, the foil aligned with the bottom of spout just broke into a straight line, that may be some reasons as below

- bad bonding strength for foil laminate

- Damage during the spout welding process

There should be separated mold with upper part and lower part as below picture shows, when these two parts presses against the spout with the foil laminate, the heat and pressure will finalize the seal of spout onto the pouch. When the mold is not adjusted in position, there may be potential damage of the foil laminate during welding process.

Drop test of our spout pouch

With all due respect, we talk about some main aspects to realize a good spout pouch, and most importantly, the customers need to see the final effect. so here, we just share with the drop test on our 1Litre and 3litre spout pouch, for your reference.

Ok, we come to the end of this post. Nevertheless, we hope every customer is able to locate the source of reliable packages for their products, especially for liquid products. Once the pouch breaks, it will cause the contamination and pollution problem, very serious accident for the product sale. If you have any questions, just reach us at office@valuepackaging.cn for further assistance.