Look at the above picture, it is a small baby jelly screw cap pouch sachet. Currently, stand-up pouches account for a large part of the packaging of baby products on the market. With a flexible combination of polymer and biopolymer film materials, self-standing jelly pouches protect jelly products during distribution while being more cost-effective. In addition, creative artistic designs can be printed on all sides of the stand-up pouch, covering all brand and sales information, making the final packaging much more attractive to consumers.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

The quality of the packaging bag directly affects the product’s market efficiency, so in this article, we analyze the material composition of the baby jelly screw cap pouch sachet.

Next, let’s get into the details of this standup screw cap spout bag.

Packaging Foil Materials

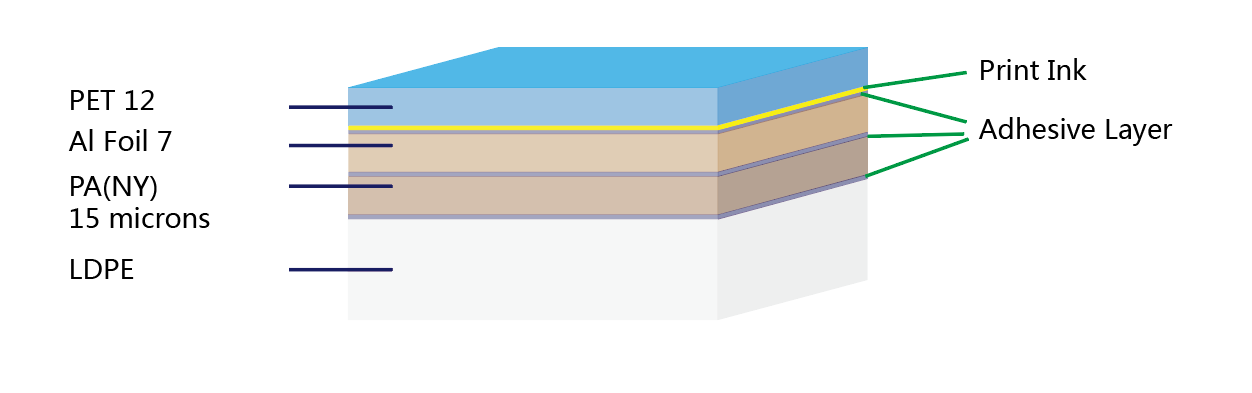

The 70-gr jelly stand-up pouch is made of 4 layers. The outer PET film is used as the printing substrate film, the AL foil and PA foil are used as the middle support layer, and finally, the LDPE film is used as the internal sealing layer.

Next, let’s get into a deeper understanding of each substrate film material.

PET Film

PET film is one of the most commonly used printing substrates in flexible packaging sachets. When it is intended for baby jelly sachets, it is able to achieve a fine appearance for the finished bag as PET film is resistant to high temperatures in the sealing process. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality, and also provide great mechanical strength to the final package.

The most commonly used thickness of PET film applied in the flexible packaging industry is 12 microns, which equals 0.48 gauge. So whenever you see PET12 or 0.48 g PET, you will know they mean the same thing.

AL Foil

Aluminum foil is a thin, pliable sheet of aluminum alloy that is widely used for the packages of various food and beverage products, as the excellent barrier properties will keep the products well protected from outside oxygen, moisture, sunlight, and contaminations. Upon our experience, aluminum foil is now widely used for coffee bags, milk powder packages, juice pouches, and baby jelly products, etc.

PA Film

PA15, which is short for biaxially orientated polyamide film, with the most used thickness of 15 microns (equal to 0.6 gauge). Usually, people call it nylon film. It is of excellent mechanical strength, anti-puncture resistance, and high barrier performance against oxygen. When it is applied to the foil laminate, usually the final package is achieved with reinforced mechanical strength, which is highly appreciated on baby jelly spout sachets.

LDPE Film

LDPE, means low-density polyethylene film, which is the most used inner sealing layer for baby jelly spout bags. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. Most importantly, LDPE membrane can be modified against the requirement of specific products, and finalize the package with great seal strength and protection. The thickness of the LDPE membrane film will be decided against the particular application.

Chemical properties

As the inner layer directly contacts the products, LDPE Film is known for its corrosion resistance, which could ensure the foil materials will not cause a chemical reaction. Some antioxidants may have certain acidities and alkalinities. Therefore, we’d better choose foil materials that have corrosion resistance.

Besides, stability is also a crucial factor for the election of the foil materials. The foil materials themselves should be kept stable during the process of storing and utilizing, not releasing harmful substances or odors.

If you have more demanding requirements for the corrosion resistance and stability property, you are advised to contact us. We are very professional in this realm to help you meet your needs.

So, how does this foil structure perform when it is intended for standup laundry detergent bags? Will it break during the transit? We made some tests for its basic properties.

Great Standup Effect

Through the below video, you may learn the standing effect when 450ml of natural antioxidants are filled into a spout bag based on this laminated foil PET/AL/PA/LDPE.

When this multi-layer structural material is used for packaging, it can make the package have a good standing effect. Compared with a single layer of PET film, the combination of PET and aluminum foil can better demonstrate the standing effect, and the aluminum foil material has good barrier properties. The puncture resistance of nylon can better protect the product. At positions where LDPE is in contact with the products and the bottom, etc., it provides a certain degree of flexibility and cushioning without affecting the overall standing effect, allowing the packaging to stand relatively stably.

Mechanical Property

The spout package will protect the natural antioxidant product during filling, transit, and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, the spout package will never be allowed to break. Can you ever imagine the leaked laundry detergent contaminating the cartons or the floor?

In the experiment, strictly follow the relevant strands and drop the packaging bag containing 450ml items freely from different heights. Serious measures are taken in our QC system, to assure each order is finalized with the expected result.

Here, we are going to fill 500ml liquid detergent into this bag, perform the drop test from 1.6 meters high, 3 times, and check if it breaks.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical values of the WVTR and OTR of the most common substrate films in flexible packaging.

A sachet of great light-shielding properties would be preferred when the formula of the baby jelly contains volatile ingredients. some food materials are contained in the jelly, which increases the requirements of barrier performance of this foil material. Based on our experience, PET/AL/PA/LDPE. foil laminate will be able to meet most of the requirements for chili sauce packages.

In the above picture, we are producing for our baby jelly screw customers, which is fully opaque and keeps the product in a fine situation even under daylight conditions.

Furthermore, WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the below table.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.01 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 0.01 |

Technical Data Sheet of baby jelly screw cap pouch sachet

Here, we attach the specification sheet of the baby jelly screw cap pouch sachet based on film material PET/AL/PA/LDPE.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to learn more about this PET/AL/PA/LDPE laminated foil, you can read it here.

Now it’s the end. You are welcome to reach us if you have any questions regarding juice pouches. Have a nice day.