Standup spout pouches are a large part of the packs for household laundry detergent liquids in the current market. The standup spout pouch utilizes a folded gusset at the bottom to hold extra products and, at the same time, presents a better display when they stand on the goods shelves. It would require the foil materials to be strong and durable to ensure the products are well protected during the filling, transit, and distribution process.

Based on a flexible combination of various polymer film materials, the foil materials are able to provide excellent barrier properties, protecting the laundry detergent from air, moisture, and light. Furthermore, a creative artwork design can be printed on all sides of the standup pouch, including all the information for branding and sale, which makes the final package more attractive to consumers.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the packaging film materials in the market, which are listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- Vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We are devoted to creating story-telling standup screw cap bags for household laundry detergent that increase product sales and establish a good brand image.

In this post, we will analyze the exact foil materials of this 1800ml laundry detergent standup bag, hoping it could serve as a reference for your products.

Ok, let’s get into the details of this standup screw cap spout bag.

Packaging Foil Materials

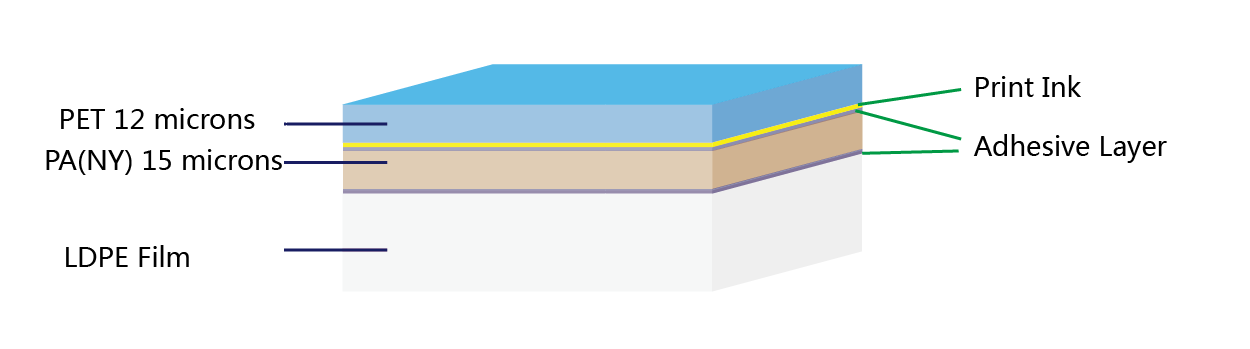

The figure below shows the composition structure of this laminated foil material used to convert this standup laundry detergent bag.

It is made of triplex layers, with the outside PET film 12 microns working as the print substrate film, the PA film 15 microns working as the middle supportive layer, and finally, the LDPE film working as the inner sealing layer. The thickness of the LDPE film should be adjusted to suit the requirements of 1800ml detergent liquids.

Next, let’s get into a deeper understanding of each substrate film material.

PET Film

PET Film is one of the most commonly used printing substrates in flexible packaging sachets. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality and also provide great mechanical strength to the final package.

The most commonly used thickness of PET film applied in the flexible packaging industry is 12 microns, which equals 0.48 gauge. So whenever you see PET12 or 0.48 g PET, you will know they mean the same thing.

PA Film

BOPA stands for Biaxially Oriented Polyamide film, which is also known as biaxially oriented nylon (short as NY) film. BOPA film is outstanding in its high tensile strength, excellent anti-puncture ability, and barrier properties, which can resist impact and punctures in numerous applications.

LDPE Film

LDPE means low-density polyethylene film, which is the most used inner sealing layer for standing juice bags. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. Most importantly, the LDPE membrane can be modified against the requirement of specific products and finalize the package with great seal strength and protection. The thickness of the LDPE membrane film will be decided against the particular application.

The property of LDPE film should be modified to resist the alkaline corrosion of the liquid detergent. Different formulas of the detergent liquids may require a different particular modification on the low-density polyethylene film. You may reach us for further assistance if you need it.

These 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. Usually, we describe the finished laminate as PET12/PA15/LDPE foil.

Great Standup Effect

Through the below video, you may learn the standing effect when 3 liters of liquid detergent are filled into a spout bag based on this laminated foil PET12/PA15/LDPE.

Mechanical Property

The spout packaging will protect the laundry detergent product while it is being filled, shipped, and distributed. The spout package will never be permitted to shatter in the event of an emergency, such as an unanticipated delivery shock or packages tumbling from the product’s shelf. Can you see the floor or boxes becoming contaminated by the washing detergent that leaked?

We put the mechanical property of this 1800ml laundry detergent standup sachet on our top priority in our manufacturing plant. Serious measures are taken in our QC system to ensure each order is finalized with the expected result.

To put it simply, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces.

Here, we are going to fill 1800ml water into this bag, perform the drop test from 1.6 meters high, 3 times, and check if it breaks.

This foil laminate can be good for detergent liquid packs of 1 liter, 2 liters, 3 liters, and even 1 gallon. Of course, there are reinforced foil structures available for more robust packages.

- PET12/PA25/LDPE

- PA15/PA15/LDPE

- PA15/PA25/LDPE

Barrier Performance

Generally, the essential formulas of a household laundry detergent liquid should include but not be limited to the list below.

- primary and secondary surfactants

- chelating agents

- enzymes

- builders

- bleaching agents

- optical brighteners

- Foam control agents

- fragrances

- colorants

- preservatives

Upon experience, all the bags and sachets for laundry detergent liquids should be light-shielding to protect the formulas so they work as expected. Strong light will decrease the cleaning effects, and some fragrances may decompose or deteriorate. Laundry detergent products will be kept from the light shielding to stay function-active as long as possible.

Furthermore, WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil to decide if this spout doy-pack is finally meeting the requirements of each customer.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 19.5 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 8.5 |

Technical Data Sheet of 1800ml laundry detergent liquids pouch

Here, we attach the specification sheet of this 1800ml laundry detergent liquid sachet based on foil laminate PET12/PA15/LDPE180.

More tests are included in this specification sheet, with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to further understand this PET/PA/LDPE laminated foil, you may just read it here.

More Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages, which leads to a more eco-friendly activity of the business. Upon the recent investigation of the detergent market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Compostable Packaging Materials

Some of our customers are trying to replace their traditional film materials with compostable items. You can see the roll in the picture below is made of 100% compostable materials for one of our customers in New Zealand.

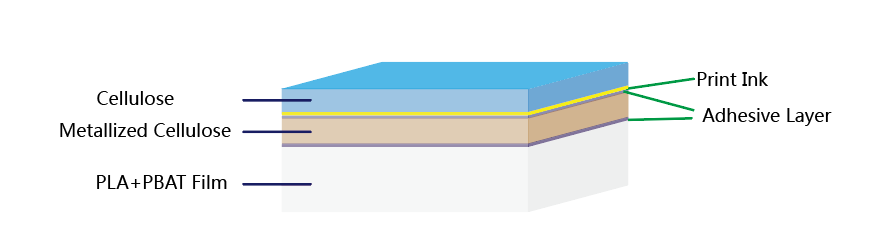

The below graphic shows clearly the foil structure for this laminated compostable foil.

The artwork is printed reversely on the inner side of plant-based cellulose film, with another layer of metalized cellulose working as the light-shielding and barrier layer, and PLA+PBAT biodegradable film working as the inner sealing layer.

However, it didn’t meet the customer’s expectations.

As explained previously, it is crucial for the laminated foil to protect the formulas of the liquid detergent in the sachet. However, for this compostable foil, the ingredients of the liquid detergent can easily penetrate into the PLA+PBAT film, which is in full contact with the liquids all the time. When a certain amount of ingredients passes through the PLA+PBAT film, it will inevitably damage the adhesive between the PLA+PBAT film and metalized cellulose, which leads to the delamination of this foil.

For this customer, the compostable foil fails to meet his requirements.

Based on this situation, the compostable foil materials will never be allowed to hold products in large volumes, like 1 liter, 2 liters, or 3 liters. That is different from the traditional polymer film materials explained above. You can contact us for further ideas if you need them. them

Fully Recyclable Mono Materials

Some of our customers are moving to fully recyclable mono-material bags, which are well-resistant to the formulas of liquid detergent. They can work well for liquid detergent up to 250ml, as the mechanical property of this recyclable bag is so far behind the traditional materials bag.

Now it’s the end. You are welcome to reach us if you have any questions regarding juice pouches. Have a nice day.