Pillow pouches are a large part of the packs for puffed food products in the current market. With a flexible combination of various polymer and biopolymer film materials, the pillow pouch can protect the puffed food product during the distribution, and be more cost-effective. Furthermore, a creative artwork design can be printed on all sides of the pillow pouch, including all the information for branding and sale, which makes the final package more attractive to consumers.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We are devoted to creating story-telling packages that increase product sales. In this post, we will analyze the exact foil materials of this 60 grams potato chips pillow bag, which assists this puffed food manufacturer in greater success in their market.

With a refined package dimension, this pillow bag accommodates 60 grams potato chips with an excellent filled level. It can present an excellent profile for the product on the goods shelves, and you are advised to have a straight understanding through the video below.

Ok, let’s get into the details of this pillow pouch bag.

Packaging Foil Materials

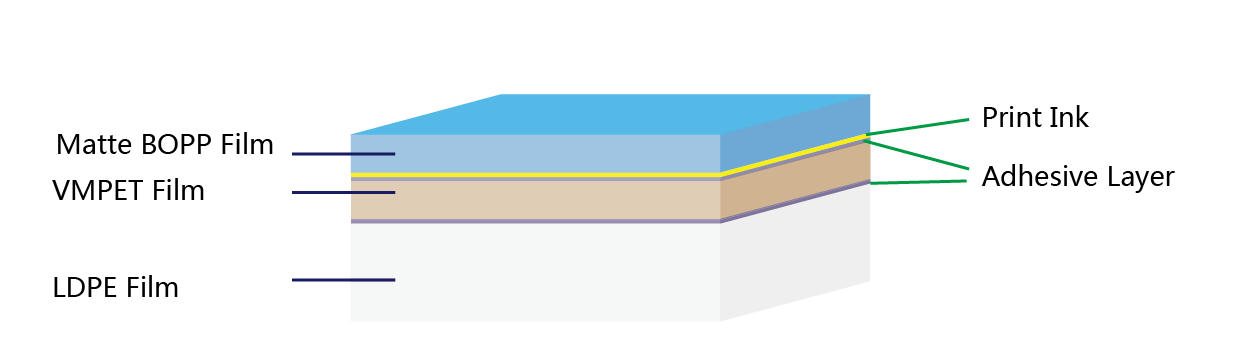

The figure below shows the composition structure of this laminated foil material which is used to convert thispotato chips pouch.

It is made of triplex layers, with the outside PET film working as the print substrate film, the second PET film working as the middle reinforced layer, and finally, the LDPE film working as the inner sealing layer.

Next, let’s get into a deeper understanding on each substrate film materials.

BOPP Film

Matte BOPP, or matte biaxially oriented polypropylene, is a polymer film with a matte finish that absorbs light instead of reflecting it. With matte finish effect on the outside, Matte BOPP film is widely used to improve visual effect and add a fashionable touch to the packaging.It’s made up of multiple layers, including a polypropylene core and tie layers, and is often co-extruded with a skin copolymer layer on one or both sides. The film is prepared through extrusion and biaxial orientation, and can be made using either the tubular or tenter frame process.

VMPET Film

VMPET12, means vacuum metallized polyester film with thickness 12 microns (equals to 0.48 gauge), is the most common used aluminum metallized films in flexible packaging field. It is with high barrier performance against moisture vapor and oxygen. The barrier performance will enable your puffed food products well.

LDPE Film

LDPE, means low-density polyethylene film, which is the most used inner sealing layer for potato chips pouch. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. Most importantly, LDPE membrane can be modified against the requirement of specific products, and finalize the package with great seal strength and protection. The thickness of the LDPE membrane film will be decided against the particular application.

The customer artwork is printed reversely on the inner side of the first PET film layer in the gravure printing system. Then, these 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process.

Usually, we describe the finished laminate as Matte BOPP/VMPET/LDPE foil. So, how does this foil structure perform when it is intended for potato chips pillow bags? Will it break during the transit?

Thickness

The paper pouch for 60 grams potato chips is composed of multiple layers with specific thicknesses. The customer artwork is printed reversely on the inner side of the first Matte BOPP film layer in the gravure printing system. The Matte BOPP18 layer has a thickness of 18 microns. This layer provides a certain degree of smoothness and surface protection. The VMPET layer, which is crucial for barrier properties, and the LDPE50 layer with a thickness of 50 microns contribute to the overall thickness and functionality of the pouch. Then, these 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. The combination of these different thicknesses of layers works together to create a pouch that can hold the almonds effectively and protect them from external factors.

Usually, we describe the finished laminate as Matte BOPP/VMPET/LDPE foil. So, how does this foil structure perform when it is intended for potato chips pillow bag? Will it break during the transit?

Great Printing Effect

The structure of Matte BOPP18/VMPET/LDPE50 gives the paper pouch an excellent printing effect. This great standup profile not only makes the product more visible and attractive to consumers but also allows for better utilization of display space in supermarkets. It gives the pouch a professional appearance, enhancing the overall presentation of the 60 grams potato chips.

Of course, the thickness of a finished foil influences the standup effect of this nut pouch after being filled. The thickness of the LDPE film used in this foil laminate is 50 microns, with the overall thickness of this Matte BOPP18/VMPET12/LDPE laminated foil around 185 microns.

The video below shows well the standup effect of this 60 grams potato chips pillow pouch.

Good Mechanical Property

The spout package will protect the potato chips product during filling, transit, and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, the spout package will never be allowed to break. Can you ever imagine the leaked potato chips contaminating the cartons or the floor?

We put the mechanical property of this 60g potato chips standup sachet on our top priority in our manufacturing plant. Serious measures are taken in our QC system, to assure each order is finalized with the expected result.

To put it simple, drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces.

In our daily QC work, there is a more reliable method to check if the bag strength is enough to meet the various conditions in the operations of filling, transport, loading and unloading, and distribution. We perform a drop test against each order, of course, the standard for this drop test should be decided against customer needs.

Here, we are going to fill 60g potato chips into this bag, and perform the drop test from 1.6 meters high, for 3 times, and check if it breaks.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The potato chips product will be kept away from these two elements to stay fresh as long as possible. However, please keep in mind that, the barrier property of this laminated foil is just a part of the measures taken to ensure the shelf life of potato chips products. The below table shows the typical value of the WVTR and OTR of this triplex foil laminate Matte BOPP/VMPET/LDPE.

Some customers may like to get superior packages with better barrier properties. In this case, the VMPET layer can be replaced by a thin aluminum foil sheet, with some foil structures as below.

- PET/Aluminum/LDPE

- MatteBOPP/Alu/LDPE

- Kraft Paper/PET/Aluminum/LDPE

This foil material proves to be working well for puffed food and snack products distributed around the country.

Technical Data Sheet of 60gr potato chips pillow bag

Here, we attach the specification sheet of this 60 grams potato chips pillow bag based on foil laminate Matte BOPP18/VMPET12/LDPE50.

More tests are included in this specification sheet with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to get a further understanding of this PET12/PET12/LDPE laminated foil, you may just read here.

More Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages which leads to a more eco-friendly activity of the business. Upon the recent investigation of the potato chips market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Compostable Packaging Materials

Compostable packaging materials are very similar to biodegradable materials. In most cases, people may do not get a clear understanding on the difference between compostable and biodegradable. Generally speaking, the compostable materials are based on biodegradable materials and when they break down, they will not cause harmful elements to the environment.

As to the materials used in our factory, the customers can just consider biodegradable equal to compostable.

The compostable packages are based on plant-based fibers like cellulose, or bio-mass like corn starch, cassava, or sugarcane. The resins derived from these resources are usually named bio-polymer, which can break down into inorganic elements under the functions of algae, bacteria, and other microorganisms.

Premium-quality compostable standup sachets and rolls are produced in our plant, which are intended to meet the particular requirements of every product. You may reach us for further ideas if you are interested in compostable packaging materials.

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, actually fully recyclable materials sachets and rolls are flooding the market for lightweight products packages in the market at much lower prices. Mono materials packages mean each layer of the multi-layer foil is made of the same resin, which can be easily processed in the human recycling system and reused for other applications. This recyclable materials sachet largely reduces the rate of plastic polymer film packages ending in landfills.

Now, the mono-materials recyclable spout sachet can be well intended for puffed food from 50~250ml, with the barrier performance as good as traditional metalized film spout doypack. That’s good enough for the packages of puffed food products.

Of course, you are welcome to reach us when you have any questions potato chips pillow pouches. Nice day.