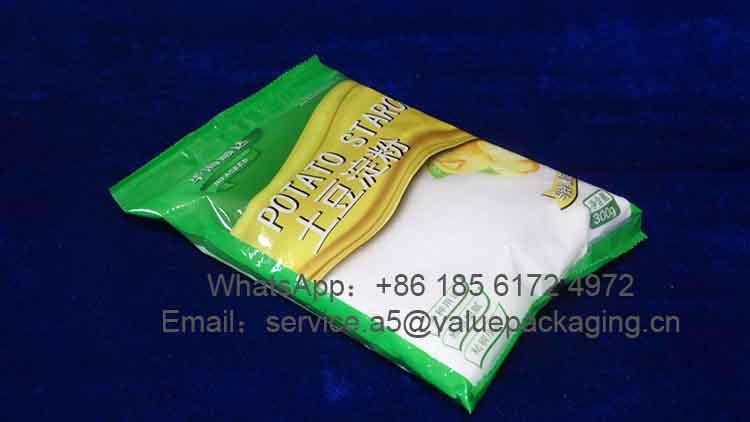

This is a pillow pouch for potato starch. Through professional packaging design, the bag can effectively prevent moisture, insects, and oxidation, thereby extending the shelf life of the product and maintaining its original quality and taste. It has good flexibility and durability, thanks to the film material it uses. The choice of material not only meets potato powder safety standards but also effectively isolates the product from pollution by the external environment. Such a perfect packaging design helps to enhance the popularity of your brand, make your product stand out, and attract customers to buy.

In this post, we will analyze the exact film materials of this 300-gram potato starch sachet, hoping it could serve as a reference for your products.

Ok, let’s get into the details of this potato powder pillow pouch.

Packaging Foil Materials

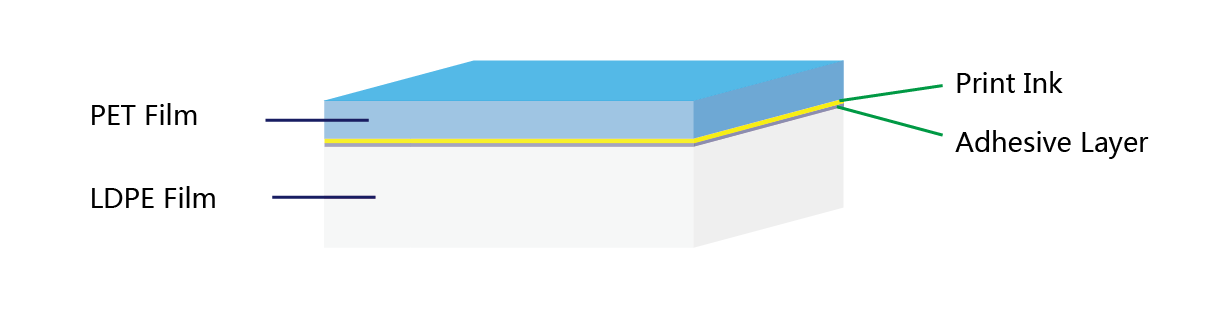

The figure below shows the composition structure of this laminated foil material used to convert this 300-gram potato starch pillow pouch.

The package is made of two layers of film. The outermost layer is the printing layer, which is made of PET film. The inner layer is the heat-sealing layer, which is made of LDPE film. Ink and adhesive are placed between the two layers of film, which provide rich color performance and packaging bonding strength.

Learn more about this foil laminate on our company website.

Next, let’s get into a deeper understanding of each substrate film material.

PET Film

PET film, sometimes BOPET film, is one of the most commonly used print substrates in flexible packaging areas. It is of great printability, mechanical strength, processing stability, high-temperature resistance, and grease resistance.

PET film is very cost-effective and has excellent performance. The pouch made of PET has strong dimensional stability, high gloss, and good barrier properties, making it very suitable for the printing layer of potato starch packaging. Because PET film has amazing impact strength and tensile strength, it can well protect the fillings in the pouch from physical damage.

LDPE Film

LDPE film is short for low-density polyethylene film, which is the most commonly used inner sealing film for multi-layer flexible packaging in various applications. It is able to provide enough sealing strength and airtight property for the final packages.

LDPE is nontoxic, non-contaminating, and has high break resistance. It’s also lightweight, corrosion-resistant, and has good chemical and impact resistance. LDPE is often used in packaging materials, such as milk pouches and food wrappers because it’s a good moisture barrier and keeps products fresh. LDPE is often used in the heat-sealing layer of food packaging bags because it is non-toxic and odorless and has good chemical resistance, impact resistance, and moisture resistance, which is why this material is chosen for potato starch sachet.

The above is our introduction to the film used in this sachet. Usually, we write this laminate structure as PET/LDPE

Thickness

As shown in the picture below, we can clearly see that the total thickness of the potato powder pouch is about 0.23 mm.

Perfect printing effect

With high clarity, great wetting tension, and great mechanical stability under kinds of conditions, PET film is a fine print substrate membrane against customer artwork. The pattern color is vividly presented by printing ink on the inside of the PET film with a rotogravure print press.

Mechanical Property

PET film has excellent mechanical properties, high rigidity, hardness, and toughness, excellent impact strength, and anti-puncture. When the package is subjected to large external forces during transportation and storage, the PET layer will play a major role in bearing and preventing the film from being overstretched or torn. LDPE has good impact resistance. When the composite material is subjected to external impact force, the LDPE layer can absorb part of the impact energy and reduce the direct impact of the external force on the PET layer, thereby protecting the entire composite material from damage.

In conclusion, PET/LDPE laminate film combines the high strength of PET and the softness of LDPE, giving the film have higher comprehensive strength.

As you can see in the below photo, we put the mechanical property of this poly sachet pouch on our top priority in our manufacturing plant. Serious measures are taken in our QC system to ensure each order is finalized with the expected result.

In short, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden, sharp forces.

Here, I will quote a video of a package drop test we did earlier, where the bag was filled with 280g potato starch and tested three times at a height of 1.6 m.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Usually, we mainly look at two indicators of the barrier performance of bags, namely Water Vapor Transmission Rate (WVTR) and Oxygen Transmission Rate (OTR). The following picture shows the barrier performance data of common substrate films.

We have this oxygen and water vapor permeation tester from Mocon to assist the measuring and control of the barrier performance in our daily QC work.

Anti-Puncture Ability

A puncture test, also known as a penetration test or force penetration, measures a material’s ability to withstand a concentrated force or the maximum amount of energy required to penetrate it. The test can be used to compare materials, assess performance over time, or determine the strength of materials like rubber, film, or membranes.

As you can see, we use standardized test methods and professional measuring instruments to evaluate the puncture resistance of packaging, which is helpful in understanding whether the packaging can be easily damaged by external objects.

More Sustainable Materials Options

As consumers pay more attention to environmental issues, they are more willing to choose products that use sustainable packaging materials. In the future, with the increase in demand for customization, the market space for sustainable packaging materials will further expand. These new packaging materials and technologies will provide companies with more choices to meet consumers’ personalized packaging needs. Survey data shows that in many countries, more than 70% of consumers prefer sustainable packaging.

Compostable Packaging Materials

The compostable packages are based on plant-based fibers like cellulose or biomass like corn starch, cassava, or sugarcane. The resins derived from these resources are usually named biopolymers, which can break down into inorganic elements under the functions of algae, bacteria, and other microorganisms.

At present, we have developed several compostable laminate film materials that can be intended for food, as shown in the list below.

- Kraft Paper/BOPLA

- Cellulose/PLA+PBAT

- Kraft Paper/Cellulose/PLA+PBAT

- Cellulose/Metallized Paper/PLA+PBAT

Fully Recyclable Mono Materials Package

Compared with the high cost of compostable foil materials, fully recyclable material sachets and rolls are flooding the market for lightweight product packages in the market at much lower prices.

Along with the improvement of barrier performance of PE film materials, their foil laminate can be enabled with a fine property to keep the sunflower seeds from moisture. A layer of PVA coating is applied over the surface of LDPE and HDPE film to enhance the moisture barrier. EVOH can be included in the biaxially orientated film, which is usually called BOPE in the flexible packaging industry, to largely improve the oxygen barrier performance.

Nowadays, we have developed some bags based on single resin film materials that are suitable for food applications. We will provide a further analysis in future posts.

This is the end of our discussion on film materials. If you have any questions, please feel free to contact us, and we will be happy to provide you with a satisfactory solution. Enjoy!