Paper bags are one of the indispensable and important components of roasted sunflower seed packages on the market. Compared to the flat pouch, Doypack is achieved with the bottom part gusseted into the pouch, which can be able to hold more product. Furthermore, the bottom gusset is going to support the pouch to stand up on the goods shelves.

There is a high requirement for the packages to preserve roasted sunflower seeds. Based on a flexible combination of various polymer film materials, the foil materials can provide excellent barrier properties against sunlight, moisture, and oxygen.

Further more, the airtight property on the re-sealable zipper will be needed to keep the sunflower seeds in freshness as long as possible after the pouch is opened by the consumers.

As you can see, a creative artwork design can be printed on all sides of the standup packaging, including all the information for branding and sale, which makes the final package more attractive to consumers.

As a well-known flexible converter located in Qingdao, China, we are utilizing the packaging film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We are dedicated to producing standup paper bags that can boost the branding and sale of sunflower seeds products for our customers, and intending to be a long-term reliable supply under our QC system.

In this post, we will analyze the exact foil materials of this 110g roasted sunflower seeds paper standup bag, hoping it helps you to decide on the perfect package.

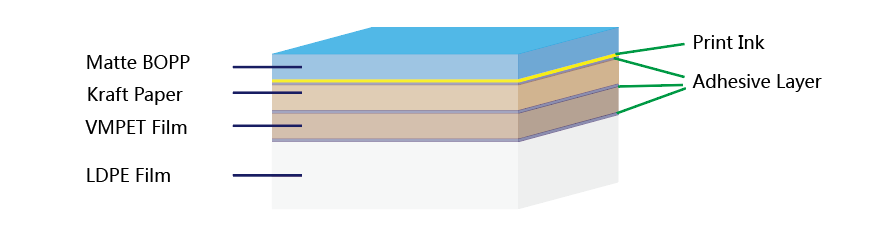

Packaging Foil Materials

As you can easily find out through the below picture, the foil structure is made of 4 layers, and we name it Matte BOPP18/Kraft Paper 50gsm/VMPET12/LDPE.

with the outside Matte BOPP film working as the print substrate film, Kraft paper and VMPET film working as the middle supportive and barrier layer, and finally, the LDPE film working as the inner sealing layer.

- Matte BOPP film, with the most common thickness of 18 microns, is working on the outside as print substrate layer.

- Kraft paper, with 50 grams per square meter, works as the middle supportive layer, which is also considered as an eco-friendly material.

- VMPET film, with the most common thickness of 12 microns, works as the main barrier layer in this foil laminate.

- LDPE film, with thickness adjustable against the requirements of the final package, works as the inner sealing layer.

Matte BOPP Film

Matte BOPP is a polymer film with a matte finish that absorbs light instead of reflecting it. It is widely used to improve visual effects and add a fashionable touch to the packaging.

Kraft Paper Film

Kraft paper is one of the most commonly used materials to increase the eco-friendliness and sustainability of the packages.

Brown kraft paper is a heavy-duty, durable, and tear-resistant paper that is usually brown in color and made from wood pulp. It’s known for its natural wood fibers and textures and has an earthy, rugged look. Kraft paper is versatile and can be used for a variety of packaging purposes.

VMPET Film

VMPET is the most commonly used aluminum metalized film in the flexible packaging field. It has high barrier performance against moisture vapor and oxygen. The barrier performance will enable your products well protected from the roaster warehouse to the consumer’s hand in a fine way.

LDPE Film

LDPE means low-density polyethylene film, which is the most used inner sealing layer for bags. It is able to provide enough sealing strength and airtight properties for the final packages.

LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. It’s also lightweight, corrosion resistant, and has good chemical and impact resistance.

LDPE is a thermoplastic polymer that is a member of the polyethylene family of plastics. It is known for its flexibility, toughness, transparency, and corrosion resistance.

LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance.

So, how does this foil structure perform when it is intended for roasted sunflower seeds paper standup bag? Will it break during the transit?

Great Standup Effect

With the supportive middle layer of Kraft paper/VMPET film, this fourfold foil laminate is stiff enough to create a good standup effect for the package up to 110g, and you may learn about the details in below video.

Excellent Mechanical Property

The paper standup bag will protect the roasted sunflower seeds product during filling, transit, and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, paper standup bags will never be allowed to break. You don’t want toasted sunflower seeds spilled on a cardboard box or the ground.

We put the mechanical properties of this 110g roasted sunflower seeds paper standup bag on our top priority in our manufacturing plant. Serious measures are taken in our QC system, to assure each order is finalized with the expected result.

Also, a drop test of a filled package is one of the reliable ways to check if the package may burst under sudden sharp forces.

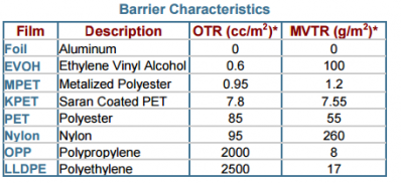

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical values of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, MatteBOPP/Kraft/VMPET/LDPE foil laminate will be able to meet most of the requirements for roasted sunflower seed bags.

For the bag In the above picture, we are producing for our Chinese customers. It is fully opaque and keeps the product in a fine situation even under daylight conditions or a humid environment.

Furthermore, WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the table below.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.85 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.2 |

Technical Data Sheet of 110g roasted sunflower seeds bag

Here, we attach the specification sheet of the 110g roasted sunflower seeds paper standup bag based on film material MatteBOPP/Kraft/VMPET/LDPE.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to learn more about this Matte BOPP/Kraft paper/VMPET/LDPE laminated foil, you can read it here.

More Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages, leading to a more eco-friendly business activity. Upon the recent investigation of the roasted sunflower seeds market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Here, we are going to share some of the trending sustainable packages for the roasted sunflower seeds market.

Compostable Packaging Materials

The compostable packages are based on plant-based fibers like cellulose, or bio-mass like corn starch, cassava, or sugarcane. The resins derived from these resources are usually named bio-polymer, which can break down into inorganic elements under the functions of algae, bacteria, and other microorganisms.

We have developed several compostable foil materials that can be intended for roasted sunflower seeds, with the list below.

- Cellulose/Metallized Cellulose/PLA+PBAT Film

- Metallized Paper/Cellulose/VMPET/PLA+PBAT Film

- Kraft Paper/Metallized Cellulose/PLA+PBAT Film

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, fully recyclable materials sachets, and rolls are flooding the market for lightweight product packages in the market at much lower prices.

Along with the improvement of barrier performance of PE film materials, their foil laminate can be enabled with a fine property to keep the sunflower seeds from moisture. A layer of PVA coating is applied over the surface of LDPE and HDPE film to enhance the moisture barrier. EVOH can be included in the biaxially orientated film, which is usually called BOPE in the flexible packaging industry, to largely improve the oxygen barrier performance.

Nowadays, we have developed some bags based on single resin film materials, that can be found in good application for roasted sunflower seeds. We will give a further analysis in future posts.

That all. Just reach us if you have any questions. Have a good time!