This screw-cap standup bag is well-intended for mineral water in the China market. At present, most of the water sold in the consumer market is packed in kinds of plastic bottles and canisters. This screw cap standup pouch makes the product easily differentiated from the crowded shelves.

This customer reached us to produce a fantastic spout pouch for his higher-level water product. We utilise the mainstream film materials in the market, to achieve the expected perfect package for this customer.

Learning from the above picture, you see an artistic artwork can be printed on all sides of the standup pouch. Based on our experience, it is going to increase the sale of product in an attractive way.

Located in Qingdao, China, we are a well-known flexible converter that uses the best film materials available in the market, as stated below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We are committed to producing high-quality mineral water packaging bags.

Ok, let’s get into the details of the packaging materials of this 4-liter mineral water spout bag.

Laminated Foil Materials

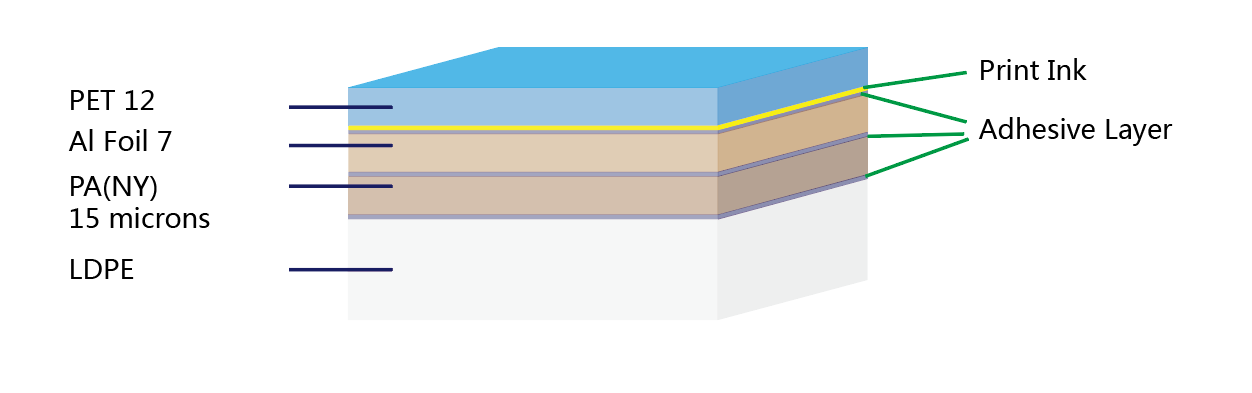

As you can learn from the above graphic, the foil materials is made of 4 layers. PET film works as the outside print layer, with aluminum foil working as the main barrier layer. There is a layer of PA film, to provide enough physical property for the finished bag, to protect 4 litres of water. LDPE film should be modified to meet the requirements of 4 liters of water. Generally, we describe the foil structure as PET12/AL7/PA15/LDPE.

Thickness

Next, let’s get into a deeper understanding of each substrate film material.

PET

PET12, is one of the most commonly used printing substrates in flexible packaging pouches. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality, and also provide great mechanical strength to the final package.

AL7

Al7, is short for aluminum foil metal sheet with a thickness of 7 microns, which is the most commonly used thickness in flexible packaging. It is of the best barrier performance among all the film materials, which can keep the freshness of water for a prolonged time.

PA

PA15, which is short for biaxially orientated polyamide film, with the most used thickness 15 microns (equals to 0.6 gauge). Usually, people call it nylon film. It is of excellent mechanical strength, anti-puncture resistance and high barrier performance against oxygen. When it is applied to the foil laminate, usually the final package is achieved with reinforced mechanical strength.

LDPE

LDPE means low-density polyethylene film, which is the most used inner sealing layer for the coffee bag. It is able to provide enough sealing strength and airtight properties for the final packages.

So, how does this foil structure perform when it is intended for 4 liters of water? Will it break during the transit?

Great Standup Effect

Upon our experience, this foil structure of PET/AL/PA/LDPE with an overall thickness of 220 microns should be stiff enough for the packages of 5-liter liquid products. When water is filled into this spout bag, the expanded bottom will provide a large foundation to support the pouch stand well on the shelf. You can see the fat bottom as below picture.

Here, we are going to fill 4000ml of water into this spout bag, and see how it finally performs.

Easily pour out from the spout

With these 4 layers bond together and converted into this bag, the body of this spout bag is soft and flexible compared to the rigid canisters and bottles. The water can be easily poured out from the spout as the consumers can distort the pouch in different angles and positions. This would be highly appreciated by the consumers in some particular applications.

Great Mechanical Property

The spout package will protect product mineral water, transit, and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, the spout package will never be allowed to break. Can you imagine the leaking water soaking the cartons and the floor?

This reinforced laminated foil is achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, on customer requirements, and you may check the exact values of this foil material in the Technical Date Sheet part of this post.

In our daily QC work, there is a more reliable method to check if the bag strength is going to meet the standards . A drop test is performed against each order, of course, the standard of this drop test should be decided against customer needs.

Here, 4 liters of water are filled into this spout bag, and it is going to be dropped from 1.6 meters high, for 3 times. We need to check if there is any break for the package.

Some customers may like to pack their liquid products up to 10 liters, and it will have a higher requirements on the foil structure. Then, we usually get a reinforced structure with PET12/AL7/PA25/LDPE. You may learn about the drop test of 10-liter spout bag here.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

The typical values of the WVTR and OTR of this triplex foil laminate PET12/AL7/PA15/LDPE are listed in below table

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.01 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 0.01 |

Upon our experience, this 4-layer foil laminate should be the best barrier film to keep water fresh in a long time.

Technical Data Sheet of 4-liter mineral water spout bag

Here, we attach the specification sheet of this 4-liter mineral water spout bag based on foil laminate PET12/AL7/PA15/LDPE180.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to get a further understanding of this PET/AL/PA/LDPE laminated foil, you may just read it here.

Ok, we come to the end, and you may reach us if you have any requirements.