standup-handle-bag-pouch-for-1-kg-wheat-flour

About a year ago, a well-known manufacturer of wheat flour in china market reached out to us for an improved standup handle bag for their products. The final pouch is presented in the above picture after a period of development. It is well intended to hold 1 kg of wheat flour, with a plastic handle on top, which is able to provide a better experience for the consumers, especially the weak people. Finally, this standup pouch indeed increased product sales by 10% in the china market. Do you want to have a further understanding on the packaging materials of this bag?

In this post, we are going to give a further analysis.

Packaging Foil Materials

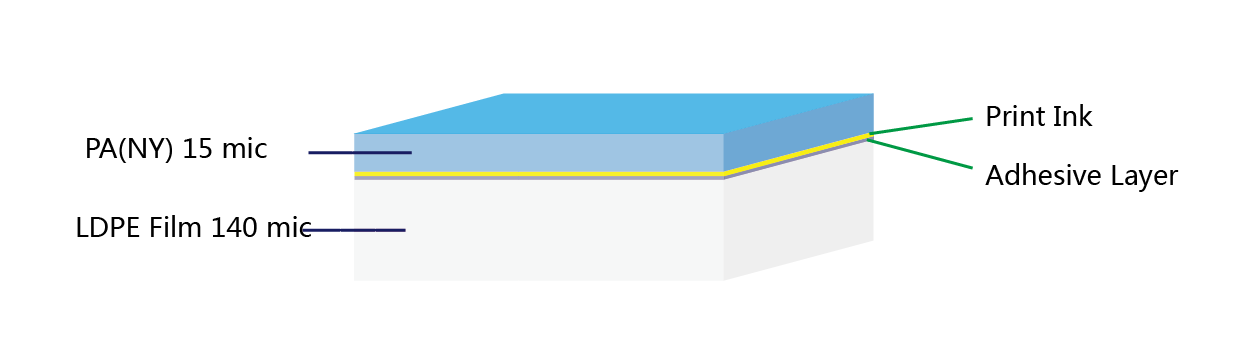

To protect 1 kg wheat flour in the package, the foil materials will have to be reinforced with robust polymer films. As you can learn from the graphic below, the foil structure is set as NY15/LDPE, which is a strong material for most flour products.

Based on these dual layers, the outside PA film works as the print and mechanical layer, and LDPE film works as the inner layer.

Next, let’s get a deeper understanding of each substrate film material.

PA

PA stands for Polyamide, which is also known as biaxially oriented nylon (short as NY) film. It’s a versatile and flexible material that’s made by biaxially stretching polyamide resins using a flat cast die process, the three-layer co-extrusion method, and the two-step tenter frame orientation.

For this kind of product, and to maintain a good standing display, PA film is a suitable choice. It will make the packaging more rigid and enhance the standing appearance.

LDPE Film

LDPE film is short for low-density polyethylene film, which is the most used inner sealing layer for standing spicy chili sauce bags. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. LDPE is nontoxic, non-contaminating, and has a high degree of break resistance.

Most importantly, LDPE membrane can be modified against the requirement of specific products, and finalize the package with great seal strength and protection. The thickness of the LDPE membrane film will be decided against the particular application.

The customer artwork is printed reversely on the inner side of the PA film layer in the gravure printing system. These 2 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. Usually, we describe this finished laminate as PA/LDPE foil.

Great Standup Effect

Look at the standing details. This bag can stand steadily.

Mechanical Property

This composite structural material packaging will protect the 1kg flour bag product during filling, transit, and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, the package will never be allowed to break. Can you ever imagine how dangerous the spilled flour as an explosive combustible?

We put the mechanical property of this 1kg flour standup doypack on our top priority in our manufacturing plant. Serious measures are taken in our QC system to assure each order is finalized with the expected result.

To put it simply, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces.

Here,we conducted a simulation test on PA/LDPE packaging by filling it with water.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The wheat flour product will be kept away from these two elements to stay fresh as long as possible. However, please keep in mind that, the barrier property of this laminated foil is just a part of the measures taken to ensure the shelf life of flour products.

With the mocon O2/H2O/CO2 permeation tester equipped in our laboratory, we can keep a closer eye on the barrier performance of each laminate foil produced in our manufacturing plant.

| Item | Standard | Unit | Value |

| WVTR | ASTM E 96 | g/m2/24hr | 16 |

| OTR | ASTM D 372-99 | cc/m2/24hr | 25 |

Usually, a metallized film layer is not necessary to protect the wheat flours, as wheat flours is not oxygen sensitive. However, it does need to be kept away from moisture, and this two-layer structure will do in most cases. For some superior wheat flour, some customers may like to choose a reinforced structure as below

- PET/PA/LDPE

- PA/PA/LDPE

Technical Data Sheet of standup handle bag for 1 kg wheat flour

Here, we attach the specification sheet of this standup handle bag for 1 kg wheat flour based on foil laminate PA/LDPE.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to get a further understanding of this PA/LDPE laminated foil, you may just read it here.

More Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages which leads to a more eco-friendly activity of the business. Upon the recent investigation of the flour market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Compostable Packaging Materials

Compostable packaging materials are very similar to biodegradable materials. In most cases, people may not get a clear understanding of the difference between compostable and biodegradable. Generally speaking, compostable materials are based on biodegradable materials and when they break down, they will not cause harmful elements to the environment.

As to the materials used in our factory, the customers can just consider biodegradable equal to compostable.

The compostable packages are based on plant-based fibers like cellulose, or bio-mass like corn starch, cassava, or sugarcane. The resins derived from these resources are usually named bio-polymer, which can break down into inorganic elements under the functions of algae, bacteria, and other microorganisms.

Image Wheat Flour Bag#

Premium-quality compostable standup sachets and rolls are produced in our plant, which are intended to meet the particular requirements of every product. You may reach us for further ideas if you are interested in compostable packaging materials.

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, actually fully recyclable materials sachets and rolls are flooding the market for lightweight product packages in the market at much lower prices. Mono materials packages mean each layer of the multi-layer foil is made of the same resin, which can be easily processed in the human recycling system and reused for other applications. This recyclable materials sachet largely reduces the rate of plastic polymer film packages ending in landfills.

Come to the end, Please reach us if you have any questions regarding flour pouches. Good day.