This is a standup bag filled with 250ml red wine, with a spout on the top to ensure airtightness and security of red wine. This package is one of the red wine doypacks we customized for our current customers who use it for promotional purposes. Frankly speaking, it is very rare in the modern market. Always, bottled red wine is ranked in the list of preferred choices of customers.

To ensure the package capacity and barrier performance, choosing a premium foil material should be prioritized. High-quality foil material has great barrier properties, protecting the product from the impact of outside factors like moisture, oxygen, and light. Besides, it could ensure the products are well protected during the filling, transit, and distribution process.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

Today, this blog may introduce the foil materials for the 250ml red wine. Hoping it could meet your needs. Our information is shown at the bottom of the passage. If you are interested in these materials, do not hesitate to contact us. Enjoy!

Packaging Foil Materials

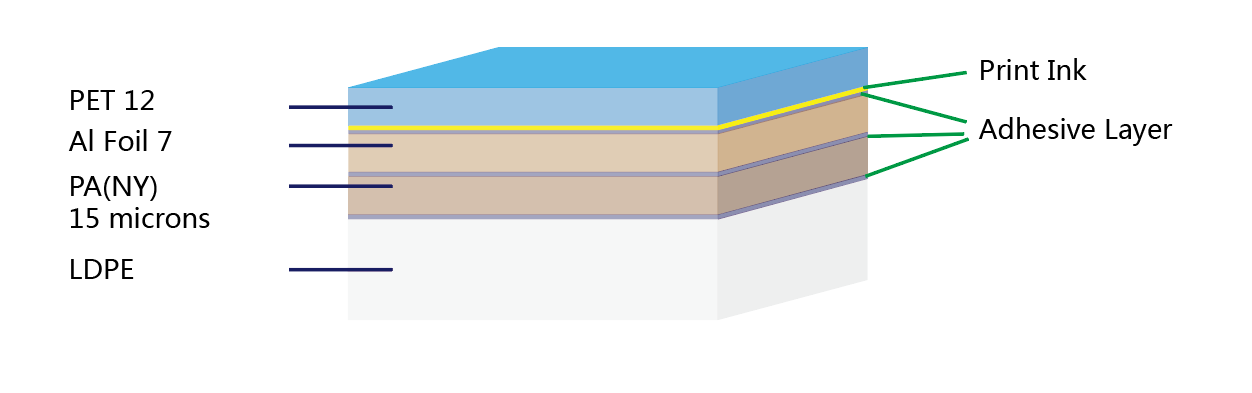

The figure below shows the composition structure of this laminated foil material used to convert this standup red wine bag.

It consists of four layers, with the outside 12 microns of PET film, working as the print substrate film. PA film 15 microns and AL Foil 7 microns work as the middle supportive layer, and finally, the LDPE film works as the inner sealing layer. The thickness LDPE film should be adjusted to suit the requirements of 250ml red wine.

Next, let’s get into a deeper understanding of each substrate film material.

PET Film

PET Film, is one of the most commonly used printing substrates in flexible packaging sachets. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality, and also provide great mechanical strength to the final package.

The most commonly used thickness of PET film applied in the flexible packaging industry is 12 microns, which equals 0.48 gauge. So whenever you see PET12 or 0.48 g PET, you will know they mean the same thing.

AL Film

Aluminum foil is a thin, pliable sheet of aluminum alloy that is often used for wrapping. It is made by rolling large slabs of aluminum until they are less than 0.2 millimeters thick, and then solidifying the molten alloy between water-cooled rollers.

Aluminum foil is 98.5% aluminum, with the remaining percentage primarily made up of iron and silicon to increase strength and puncture resistance. It has many properties, including durability, non-toxicity, oil-proofness, chemical resistance, and good thermal conductivity.

With the best barrier properties, Aluminum can effectively block the penetration of light, preventing light-sensitive products such as medicines and cosmetics from deteriorating due to light. It can also block the penetration of gases such as oxygen and water vapor, maintaining a dry and oxygen-free environment inside the products and extending the products’ shelf life. At the same time, it has excellent heat capacity.

PA Film

BOPA stands for Biaxially Oriented Polyamide, which is also known as biaxially oriented nylon (short as NY) film. It’s a versatile and flexible material that’s made by biaxially stretching polyamide resins.

BOPA film has many properties that make it useful for various applications, including packaging, consumer goods, and industrial uses:

- Barrier properties: BOPA film can act as a barrier against moisture and oxygen. It can also be used to package greasy or aggressive substances.

- Mechanical strength: BOPA film is flexible, has high tensile strength, and is resistant to impact and punctures.

- Other properties: BOPA film is also transparent, glossy, and can be printed on.

LDPE Film

LDPE, means low-density polyethylene film, which is the most used inner sealing layer for standing juice bags.

LDPE is lightweight, easy to fabricate, and has good chemical and impact resistance. LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. Most importantly, LDPE membrane can be modified against the requirement of specific products, and finalize the package with great seal strength and protection. The thickness of the LDPE membrane film will be decided against the particular application.

It is often used for manufacturing plastic goods like cling wraps, juice containers, orthotics, and prosthetics.

The customer artwork is printed reversely on the PET film layer in the gravure printing system. Then, these 4 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process.

Usually, we describe the finished laminate as PET12/Al7/PA15/LDPE foil.

Therefore, how does this foil structure perform when it is intended for standup red wine bags? Will these foil materials effectively protect the red wine?

Great Standup Effect

With 4 layers combined together, PET12/AL7/PA15/LDPE foil laminate should be stiff enough to present a fine standing effect for products up to 1 litre. Of course, the stiffness can be further improved when the thickness is increased. It will be going to provide a gorgeous standing profile for 250ml of red wine.

Excellent Mechanical Property

The spout package will protect the red wine product during filling, transit, and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, the spout package will never be allowed to break. Can you ever imagine the leaked wine contaminating the cartons or the floor?

We put the mechanical property of this 250ml red wine standup sachet on our top priority in our manufacturing plant. Serious measures are taken in our QC system, to assure each order is finalized with the expected result.

To put it simply, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces.

Drop Test Video #

Here, we are going to fill 250ml water into this bag, and perform the drop test from 1.6 meters high, for 3 times, and check if it breaks.

Barrier Performance

Generally, the essential formulas of a red wine should include but not be limited to the list below.

- Tannin

- Alcohol

- Acid

- Polyphenol

- Sugar

Upon experience, all the bags and sachets for red wine should be oxygen-blocking and moisture-blocking to protect the formulas work as expected. Besides, it should also be light-shielding, because strong light will increase the deteriorate. Red wine will be kept away from the light, oxygen,and vapor to stay function-active as long as possible.

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). However, please keep in mind that, the barrier property of this laminated foil is just a part of the measures taken to ensure the shelf life of red wine products. The below table shows the typical value of the WVTR and OTR of this triplex foil laminate PET12/AL7/PA15/LDPE.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.01 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 0.01 |

It is easy for the customers to understand this foil laminate is not of excellent barrier performance, as there is not any high barrier film layer in this foil structure. For some customers who have higher requirements for the flavors and freshness of their red wine products, a foil laminate with higher barrier properties is inevitably needed.

Technical Data Sheet of 250ml Red Wine Pouch

Here, we attach the specification sheet of this 250ml red wine sahcet based on foil laminate PET12/AL7/PA15/LDPE.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

- More Sustainable Materials Options

Now it’s the end. You are welcome to reach us when you have any questions. Have a nice day.