When you standup straight, actually you look great, that’s the same thing that will happen to your packages. Every product would like to get a gorgeous of standup effect when it is displayed on the good shelf, which is always an effective way for enhaned branding and attract new customers. Crowded with numerous brands, it is always important to stand out when the consumers lay their first eyesight on the products.

In reality, the stiffness of the foil materials matters much on the overal standing effect of a filled package. As you can see the below picture, I just grab a piece of compostable foil laminate with dimension Width20*38cm, and it will not easily bend to itself. This foil will of course make up a great standup package.

However, some of the home compostable kraft paper foil laminate may not be so stiff, and you may watch the video below to understand the standing effect of Kraft paper 45gsm/PLA+PBAT 50microns foil pouch.

Actually, kraft paper 45gsm is the minimum weight applied in the flexible packaging area. It can make up the compostable doypack at the lowest cost. For some products that do not require high mechanical strength, like spices, cookies, kraft paper 45gsm with PLA+PBAT liner sealing layer may be the best option for sustainable packages.

By below video, you may have a further understanding on the performance of kraft paper 45gsm.

In the commercial market, there are also kraft paper with some other weight available, like 50gsm, 60gsm, 70gsm, and 80gams maximum in our converting area. Actually, along with the increase of the weight of kraft paper, the stiffness increases. Usually kraft paper 70gsm and 80gams will be so good to achieve foil laminate with enough stiffness for most of the packages.

By below video, you may have a more clear understanding on the stiffness of compostable Kraft paper/PLA+PBAT foil when the weight of kraft paper increase from 45gsm to 80 gsm (short for grams per square meter).

So, in actual application, the most economical way to improve the stiffness of a compostable kraft paper foil pouch is to choose a larger-weight paper substrate. The price of kraft paper is only 30~40% of the PLA+PBAT sealing layer, so for a final compostable package, when the content of kraft paper increases, actually the overal price of the finished package lowers.

We would choose Kraft Paper 70gsm/PLA+PBAT or Kraft Paper 80gsm/PLA+PBAT to achieve the compostable kraft paper doypack pouch, with much better standup effect.

However, this is not always the best choice for the customers. As for some applications, the customer would need to get a more strong and robust package for larger volume or heavy weight products, like 1kg of roasted coffee beans, 1000g powder nutritions. and sometimes, the barrier performace should be improved at the same time to ensure a great protection for the inside products.

In this case, we have to think up another method, to apply a reinfored middle layer into the structure, to make it more stiff, high barrier against moisture and oxygen, more strong and robust, and of course, the most important, compostable.

Cellulose Film Material

Cellulose film is made of plant fiber materials with high gloss and transparency, which can be a print substrate in flexible packaging area. Furthermore, it can be a reinforced middle supportive layer for some standup pouch packages as it is of great stiffness and high tensile strength with very small elongation, please check the typical values of

| Cellulose Film 35mic Machine Direction | Maximum Strength(N) | Tensile Strength (Mpa) | Elongation |

| #1 | 44.54 | 84.84 | 3.61 |

| #2 | 60.63 | 115.49 | 6.60 |

| #3 | 59.12 | 112.61 | 8.46 |

| #4 | 49.06 | 93.45 | 4.17 |

Watch the video here for the test process https://www.youtube.com/watch?v=HtWzHG1zl6o

| Cellulose Film 35mic Transverse Direction | Maximum Strength(N) | Tensile Strength (Mpa) | Elongation |

| #1 | 40.81 | 77.74 | 24.53 |

| #2 | 39.34 | 74.93 | 21.69 |

| #3 | 43.77 | 83.37 | 36.88 |

| #4 | 38.35 | 73.05 | 10.21 |

Watch the video here for the test process https://www.youtube.com/watch?v=0f71Fl4Mg7M

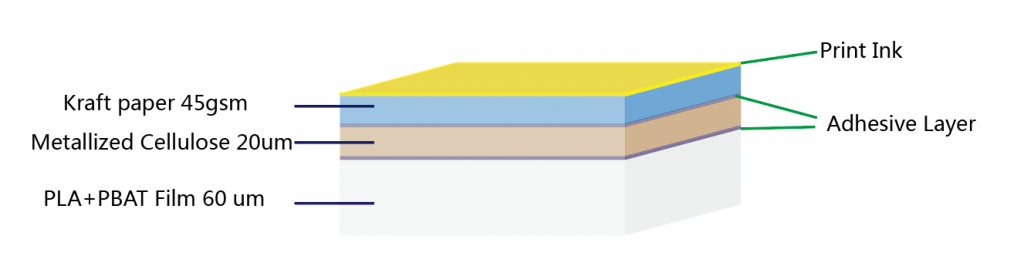

The structure of the reinforced compostable laminate is Kraft Paper45gsm/Cellulose20/PLA+PBAT, which can present the standup pouch with much better standing effect.

Again, the final pouch package is more strong and robust, and with a person standing on the top of the inflated bag, it will not burst.

So, this reinforced foil lamiante can be used for heavy weight or larger volumes of products packages.

Metallised Cellulose Film

With a thin layer of aluminum atoms depositing on the top surface of cellulose film substrate, metallized cellulose is enabled with glossy metallic effect, higher barrier performance, sunlight shielding performance. When metallized cellulose film works as middle layer, the final laminate of Kraft Paper 45gsm/Metallized Cellulose20/PLA+PBAT60um will be of excellent mechanical property, high barrier performance which can be well intended for sustainable package for coffee beans, nutritions, milk powder etc.

Below picture shows the side gusset pouch with foil structure Kraft Paper 45g/Metallized Cellulose20/PLA-PBAT film 60um well intended for 1000 grams of roasted coffee beans.

The side gusset package is strong enough to be a great protection for the coffee beans to be filled, distributed, transported all the nation around without breakage. In our daily QC work, we perform drop test to check if the pouch is achieved in the expected way.

You are advised to watch the video below, with the filled pouch droped from 1.6m high for 5 times, and it finally does not burst.

Ok, that’s all what I need to say about imprving the stiffness of the compostable kraft paper foil pouch, and you may also watch the video for a further understanding. Enjoy!