Hello, This is Bruce Dou, packaging specialist in China. As the world becomes more and more demanding for eco-friendly pouch packages, our company have developed recyclable packaging materials and compostable packaging film materials, and standing pouch packages, to meet the various requirements from the customers.

And here, in this post, I will try to revert the reliable information regarding these eco-friendly packages to you, and hope it helps for your choice. Of course, I will revert more when we get more knowledge and experience in this field.

Eco-friendly Package: Recyclable, Biodegradable or Compostable?

When we talk about eco-friendly packages, actually we are coming to a complex topic, as there exists different grades for environmental friendly processes, and at the same time, the customers may hold very different ideas against eco-friendly packages. Especially, when it comes to compostable and biodegradable, some customers may get more confused, as usually these two words are often alternatively used when we talk about eco-friendly packages. So, please allow me to give a basic articulation on these terms.

Recyclable Packages

Recyclable packages usually means the discarded packages after consuming of the inside products can be recycled into our industrial system and processed into granules, and then make into other forms of packages (like poly mailer bags) or other products (such as plastic barrels, molded plastic products etc), with graphic shown as below.

So, when a package is defined as recyclable, usually the package will have to be in a single polymer material that can be re-processed. In the package materials system, polypropylene (short as PP) or polyethylene (short as PE) occupied the largest percentage of recyclable film materials.

If a foil material contains 2 or even more kinds of film materials, usually it should not be taken as recyclable, for example the multilayer foil laminate of PET/LDPE is not taken as recyclable.

At present, the recycled package supplied by our company is mainly listed as below

- LDPE Film Bag/Package

- CPP film Bag/Package

- BOPP/VMCPP Foil Laminate

- PE Mono Materials Laminate

You are advised to learn more about our recycled package here What film materials are really recycled for plastic pouch package?

Biodegradable Packages

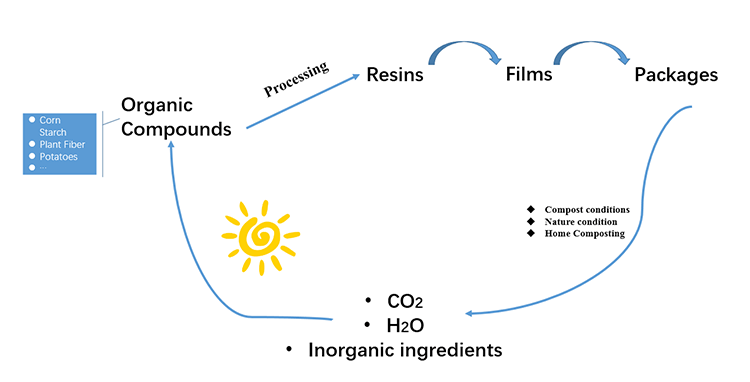

Biodegradable packages mean the film materials are able to break down into small compounds which are not harmful to the environment, like CO2, water, and other inorganic molecules. Plant-based film materials are usually considered biodegradable, which should undergo the degradation process under the action of naturally occurring micro-organisms like alage, fungi and bacteria.

Of course, different film materials may degrade at different rates, some may take several months, and some may take 2-3 years

Compostable Packages

Compostable packages mean the foil materials are able to break down into small natural elements which should do not do harm to the environment. Furthermore, during the composting process, CO2, water and some other inorganic compounds may be produced, with the end products having various benefits like enriching and boosting soil health.

So, concerns arise in the compost industry, as to make the packaging materials well composted in the industrial composting facility, a certain period will have to be limited. As for some biodegradable packages, they may take much longer time than the composting period, which is not accepted by the compost industry. Usually, the package materials can be labeled compostable when the breakdown process takes about 90~180 days. You may refer to European Standard EN 13432 to get a further understanding of the down criteria for what can or can not be stipulated as compostable or biodegradable.

Herewith, I am going to talk about the compostable substrate film materials and multilayer foil rolls, and standing pouch packages that are developed on this basis.

Compostable Substrate Film Materials

At present, my company develop compostable foil roll and standing pouch packages based on below list which should be considered compostable.

- PLA+PBAT Blown Film

- BOPLA Film

- Cellulose Film

- Metallized Cellulose Film

- Kraft Paper

- Metallized paper

Let’s get further into each item!

PLA+PBAT Film

PLA is short for polylactic acid, which are usually derived from corn starch or potato starch, and intended to compost under home/garden or industrial conditions. Usually, it needs to be mixed with PBAT in produce process to achieve a commercial compostable film.

PLA film is of good sealing property, which enables itself as a good inner sealing layer in the multilayer foil laminate.

Learn more about PLA film here: PLA FILM INTRODUCE, PRODUCE, PRINT, LAMINATE, CONVERTING, CERTIFICATES, TECHNICAL DATA SHEETS, TESTS AND APPLICATIONS

BOPLA Film

BOPLA film is short for biaxially-orientated polylactic acide, which is usually derived from bio-chemical materials like corn tarch, potato tarch, which can be fully biodegradable or compostable in nature conditions. After biaxially orientated, the final film are enable with below property.

- Good clarity

- Good tensile strength

- Good stiffness and toughness

- Good printability

- Good sealing property

In actual application, BOPLA film can work as outside print film and inner sealing layer, which makes BOPLA film quite capable of different foil structures.

Learn more about BOPLA film here: BOPLA FILM INTRODUCE, PROPERTY, PRODUCE, LAMINATE, CONVERTING, CERTIFICATES, TECHNICAL DATA SHEETS, TESTS AND APPLICATIONS

Clear Cellulose Film

Cellulose film (usually short as PT film) is considered one of the renewable and compostable packaging films with great potential applications. It is usually made from the fiber plants such as cotton, wood, hemp, etc, which are the same materials for producing paper.

With fine tensile strength, good clarity, good printability, PT film can work great as outside print substrate with vivid artwork print up to 10 colors. In some foil laminate, PT film can also work as middle support layer.

Learn more about Cellulose film here: CELLULOSE FILM INTRODUCE, PRODUCE, PRINT, LAMINATE, CONVERTING, CERTIFICATES, TECHNICAL DATA SHEETS, TESTS AND APPLICATIONS

Metallized Cellulose Film

Metallized cellulose film is to deposit a thin layer of aluminum atoms onto the surface of cellulose film which is able to achieve below properties.

- Good barrier performance against moisture and oxygen

- Sunlight resistance

- Bright metallic effect

Generally, metallized cellulose film is going to function in the middle layer for barrier purposes.

Learn more about metallized cellulose film here: METALLIZED CELLOPHANE FILM INTRODUCE, PROPERTY, PRODUCE, LAMINATE, CONVERTING, CERTIFICATES, TECHNICAL DATA SHEETS, TESTS AND APPLICATIONS

Kraft Paper

Kraft paper, which is usually made from plant and wood fiber, finds itself a good film layer in packaging and printing applications as of below properties.

- Strong

- Economically valuable

- Good printability

- Good stiffness

- Eco-friendly

Kraft paper can work as an outside layer and carry the artwork print in a quality visual effect, and also it can work as a middle supportive layer.

Learn more about kraft paper here: KRAFT PAPER INTRODUCE, PRODUCE, LAMINATE, CONVERTING, CERTIFICATES, TECHNICAL DATA SHEETS, TESTS AND APPLICATIONS

Metallized Paper

Metallized paper, similar to metallized film, is achieved with a thin layer of aluminum atoms onto the surface of paper substrate (of course, with many variants of paper types), and finally a bright metallic paper is finalized, with property as below

- High barrier performance against common paper

- Bright metallic, that can create great metallic background for artwork printing

- Fragrance protection

- Better sunlight shielding

Metallized paper can work as an outside print substrate which can be printed in flexo or gravure method. Also, metallized paper can work as middle barrier and support layer in some foil laminates.

Learn more about metallized paper here: METALLIZED PAPER INTRODUCE, PROPERTY, PRODUCE, PRINT, LAMINATE, CONVERTING, CERTIFICATES, TECHNICAL DATA SHEETS, TESTS AND APPLICATIONS

Compost Certificates

Kraft paper is made of plant fiber which can generally be taken as compostable even though few of the paper manufacturers would take time to get its product certificated. Metallized paper should be taken as compostable as there is a thin layer of aluminum deposited onto the paper surface, and the thin aluminum layer will vanish under the reaction of oxygen and moisture.

So, for kraft paper and metallized paper, our suppliers do not get their products certificated by authorities. And here we are going to list the compostable certificate for Cellulose film, BOPLA film, and PLA film. You are advised to have a further understanding in below links.

Compost Conditions

The degradation process of the compostable film materials will be quietly dependent on moisture, temperature. and the density of microorganisms, like bacteria, fungi, and algae. Under ideally expected compost conditions, the film materials would need 90~180 days to degrade up to 98%. In winter cold days, the degradation process would take a longer time.

Here, I am going to perform the compost test of these film materials under home/garden conditions and buried in nature soils.

Compost Test

Home Compost Conditions

Dated on Nov 26th, 2021, I filled the home compost container with below items.

- Vegetable leaves

- Grass

- Orange peel

- Banana peel

- Tomato leftover

- Compostable Foil laminates

- Compost bacteria

- Organic fertilizer that is intended to boost the multiply of the bacterias

It is winter in North China, and the low temperature will prolong the period needed to achieve the compost process, and of course, I am going to keep you updated with the degradation situation in below post.

COMPOST TEST OF PACKAGE FILM MATERIALS UNDER HOME/GARDEN CONDITIONS BY CHINA MANUFACTURER

Nature Soil Conditions

The degradation process will take a much longer time in natural soil conditions as the density of microorganisms, moisture, temperature, and ventilation factors are not as good as compost conditions.

But how much longer?

So, Dated Nov 27, 2021, I started the test with these compostable film materials buried in the soil of our garden.

Surely, I will keep everyone posted with the breakdown situation every 6 months. You may follow this post to keep updated.

THE BIODEGRADING PROCESS OF COMPOSTABLE FILM MATERIALS BURIED IN NATURE SOIL

Compostable Multi-layer Foil Laminate

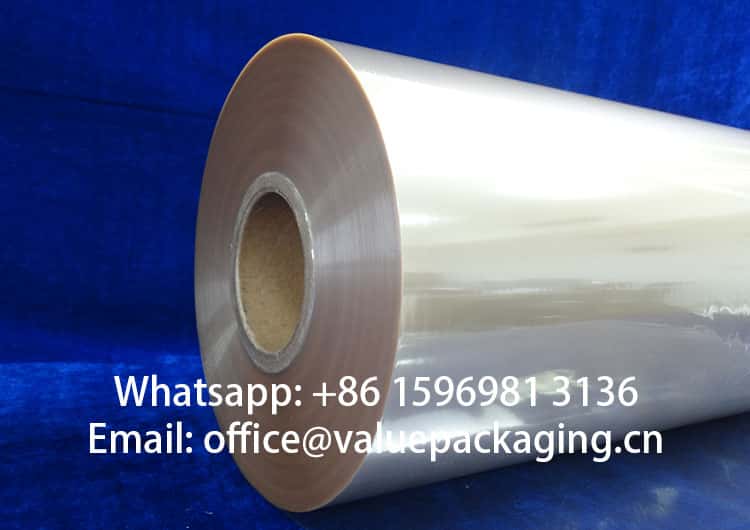

Based on the compostable substrate film materials above, my company has developed more than then foil structures that are able to meet various requirements from the different customers, and here I am going to introduce the most used items to you.

BOPLA/PLA Foil

BOPLA/PLA foil pouch makes one of the most popular compostable multi-layer standing pouches in the present market, however, it can not be intended for high barrier packages. BOPLA film is working on the outside print layer, with great tensile strength, good clarity, printability, this foil laminate can realize the print of customer artwork up to 10 colors in gravure or flexo method, with very vivid effect.

Learn more here: What’s BOPLA/PLA compostable foil laminated material and its property

Cellulose/PLA Foil

Cellulose/PLA foil pouch should be another economical compostable option for products that do not need high barrier performance. PT, which is short for cellulose film or cellophane film, is usually made of plant fiber, the same materials as paper.

With high-temperature resistance, PT/PLA foil is able to realize a smooth and neat surface in the bag-making process.

Learn more here: What’s Cellulose/PLA Foil Laminate Compostable Standing Bag Pouch Package

Kraft Paper/PLA Laminated Foil

Kraft paper is widely used for compostable pouch packaging as it is able to achieve most of the expected property at the lowest cost. When kraft paper is laminated with PLA film, this foil is going to make a good-standing pouch with fine sealing properties.

Most products that does not need strict protection against moisture and oxygen, or do not need longer shelf life can be packed in this kraft paper/PLA foil standing bags.

Learn more here: What’s Kraft Paper/PLA Laminated Foil Eco-friendly Standing Pouch and its property

Kraft Paper/BOPLA Foil Material

Kraft Paper/BOPLA Foil Material is of great stiffness, and some customers may do not like it to work as roll foils on the FFS machine. However, it can be converted into standup pouch with excellent standing effect.

As BOPLA film is of good clarity, ultra-clear front window can be realized on this foil pouch, which is much favored by some customers.

Custom artwork can be printed onto kraft paper in quality effect.

Learn more here: What’s Kraft Paper/BOPLA Film compostable film standing bag packaging

Metalized Paper/PLA Foil Structure

Metalized Paper/PLA foil structure should be the most economical choice when the customers would like to combine a metallized barrier layer into the package. It can be well intended for some products that needs to be well protected against moisture, oxygen, sunlight, like coffee beans, dry nuts, snacks, seeds, etc.

Custom artwork can also be printed on paper surfaces. Laser rainbow/Gold metallic can be achieved at the customer’s preference.

Learn more here: What’s Metalized Paper/PLA Film Biodegradable Standup Bag Packaging and Its Property

PT/MPT/PLA Multilayer Foil

This PT/MPT/PLA multilayer foil is able to realize high barrier packs for products that are sensitive to moisture, sunlight or oxygen, like coffee beans, dry nuts, seeds etc, with each layer function as below.

- PT, short for cellulose film, working as outside print substrate film, and we can realize the customer artwork up to 10 colors.

- MPT, short for metallized cellulose film, that is similar to Metallized PET film, which is intended to provide high barrier performance for the package, and also working as a middle supportive layer.

- PLA film, working as inner sealing layer, that is able to achieve very good sealing strength up to 30~35N/15mm, that is able to meet the requirements for most products.

You are advised to get a further understanding on this foil laminate and its property here.

What is PT/MPT/PLA Eco-friendly High Barrier Multilayer Foil Standing Coffee Pouch and its property

Metallized Paper/Cellulose/PLA Foil Laminate

Metallized Paper/Cellulose/PLA Foil Laminate is able to provide much better barrier performance and mechanical strength for the package than Metallized Paper/PLA foil. It should be able to hold up to 5 kgs of roasted coffee beans in self-standing packaging bags. This foil structure is highly advised for roasted coffee beans package, dry nuts packs, and snacks pouch.

You may get a further understanding here: What’s compostable Metallized Paper/Cellulose/PLA Foil Self-standing Bag and Its Property

Kraft Paper/Metallized Cellulose/PLA Multilayer Foil

Kraft Paper/Metallized Cellulose/PLA film is a good choice when the customer would like to apply water-based ink to achieve his artwork print. The ink can be printed by flexo printing up to 8 colors.

Metallized cellophane film is well intended to provide enough barrier property and mechanical support layer for the foil laminate, so this foil laminate can be then processed into kinds of standing doypacks or roll foils.

Learn more here: What’s Kraft Paper/MPT/PLA Sustainable Multilayer Foil Materials and Its Property

PT/Metallized Paper/PLA Film Materials

For this PT/Metallized Paper/PLA film materials, clear PT film is working as the outside print substrate, which can enable the customer artwork printed up to 10 colors in a much more vivid effect than kraft paper.

For this PT/Metallized Paper/PLA film materials, clear PT film is working as the outside print substrate, which can enable the customer artwork printed up to 10 colors in a much more vivid effect than kraft paper.

Learn more here: What’s Cellulose/Metallized Paper/PLA Eco-friendly Foil Laminate and Its Property

Kraft Paper/PT/PLA Film

Crystallized PLA cups becomes more and more popular for coffee capsule as it is able to fully degrade in an eco-friendly way. To well seal the eco-friendly capsule, my company have developed kinds of kidding foils to meet the various requirements for the customer, with some purpose as below

- Good Sealing Strength

- Short Sealing Period

- Easy to puncture

Kraft Paper/PT/PLA is a fine foil structure we figure out to make the ideal foil. Of course, you may get a further understanding of other lidding foils in the below post.

Basic knowledge and properties of fully compostable lidding foil for coffee capsule

We are developing more foil structures for the compostable packages to meet various requirements from our customers, and you may learn more here: Most common used compostable multilayer foil material structures

Barrier Performance: WVTR and OTR

WVTR is short for water vapor transmission rate, and OTR is short for oxygen transmission rate, and these two factors are the most important parameter to evaluate the barrier performance of a substrate film or foil laminate. Here we are going to list the WVTR and OTR values for the most used compostable multilayer materials.

| Biodegradable Foil Laminate | WVTR(g/m2/24hr) | OTR (cc/m2/24hr) |

| BOPLA40/PLA+PBAT60 | 62.2 | 267 |

| Cellulose30/PLA+PBAT60 | 131.5 | 5.6 |

| Kraft Paper45g /PLA+PBAT60 | 184 | 742 |

| Kraft Paper45g/BOPLA40 | 141 | 380 |

| Metallized Paper69g/PLA+PBAT40 | 27 | 127 |

| Cellulose20/Metallized Cellulose20/PLA+PBAT60 | 18 | 2.1 |

| Cellulose20/Metallized Cellulose20/BOPLA40 | 19 | 2.2 |

| K-Cellulose22/Metallized Cellulose20/PLA+PBAT60 | 8 | 0.5 |

| Metallized Paper 69g/Cellulose30/PLA+PBAT60 | 5.6 | 1.12 |

| Kraft45g/Metallized Cellulose20/PLA+PBAT60 | 26 | 2.22 |

| Cellulose30/Kraft45g/PLA+PBAT60 | 19 | 117.2 |

| Cellulose30/Metallized Paper69g/PLA+PBAT60 | 8.9 | 1.1 |

Standing Pouch Packages

Standing pouch packages are highly welcomed and used for nearly each and every of the daily products. As to these eco-friendly sustainable foil materials, we are trying to get the best of them to meet the requirements for our customers. And here I am going to introduce some of the main aspects that most customers concern about.

Amazing Print Effect

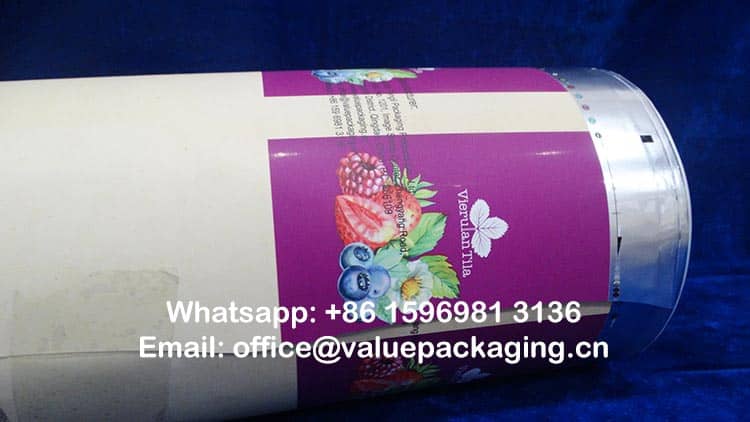

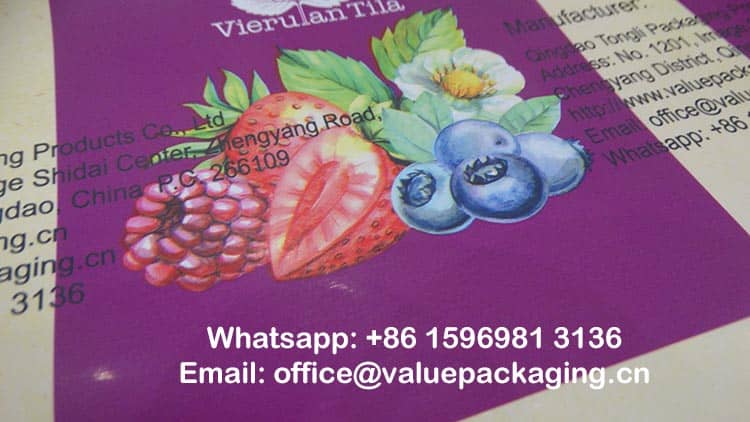

Artwork design can be printed on outside film or paper. Physical product image can be printed with fantastic effect on the compostable package, just like the picture with blueberry and strawberry, which is realized by CMYK overlapping + white background.

You are advised to read here for more understanding on the artwork print on compostable standing bag packages: Artwork print on compostable pouch packages.

Great Matte Finish Effect

Matte lacquer can be achieved on the outside of compostable bag with great quality, quite uniform, good adhesion to the print substrate, and scratch resistant.

You are advised to learn more about the matte lacuqer varnish effect by this post. How is about the matte lacquer varnish effect on compostable bag

Standing Effect

Standing effect should be the first consideration when we choose these pouches, and upon our experience and test, the foil structures developed by my company are able to present good standing effect for most packages.

Learn more here: How is about the standing effect for our eco-friendly compostable standup pouch packs

Mechanical Strength

The biodegradable pouch needs to be strong to be a enough good protection. Of course, these different foil materials are performing at different levels, and we will advise to meet the customer’s requirements at the lowest cost.

For above picture, it shows me standing on the well-sealed pouch with foil structure Metallized Paper69g/Cellulose film23/PLA60. I weigh 72 kgs and when I stand on the pouch for 10~15 seconds, there is not any break or leakge or damage to the pouch. You can imagine how strong this pouch is.

Learn more here: Mechanical Strength Test for Eco-friendly Compostable Multilayer Foil Packaging Materials

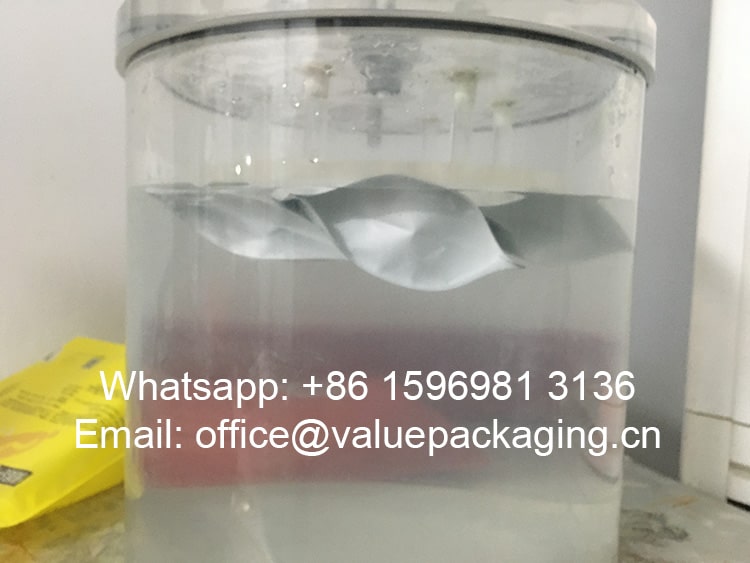

Airtight Property

The standing pouch will have to be enabled with good airtight properties for the inside products, otherwise the products may easily deteriorate. Above picture shows the airtight property test for these compostable zipper pouches, which does not leak under minus 70Mpa.

You may learn more about the airtight property test in this post.

Airtight property test for multilayer compostable standing zipper pouch package

Zipperlock Re-sealability

Zipperlock is option for our compostable standup bags, of course, the zipperlcok needs to be with good re-sealability to make sure the package will be of good airtight property after repeatedly open-and-close.

You can learn more about the test process here: Zipperlock Re-sealability Test for Eco-friendly Biodegradable Standup Zipper Bag

Package Types

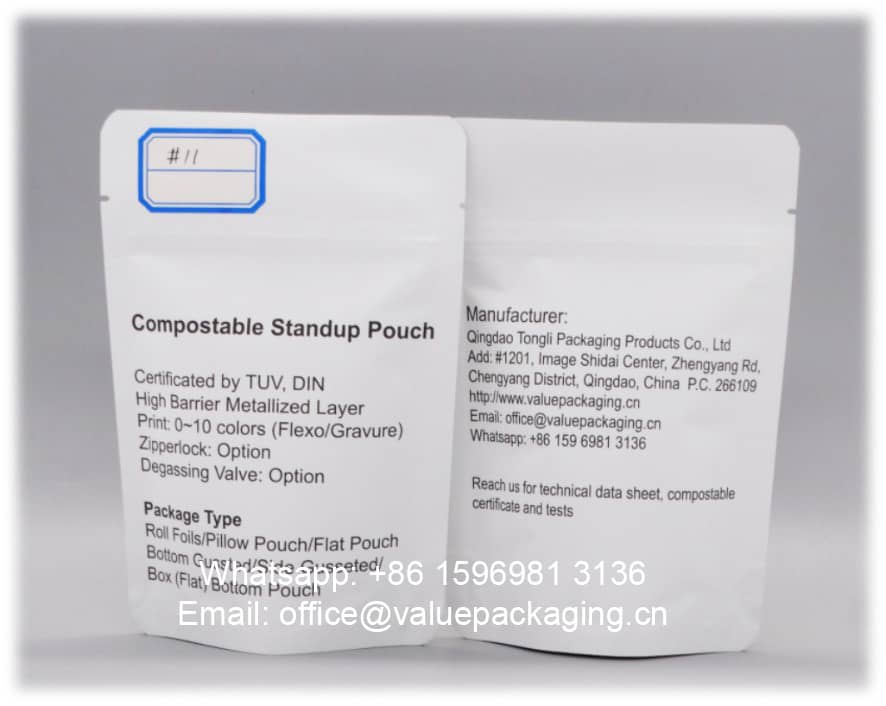

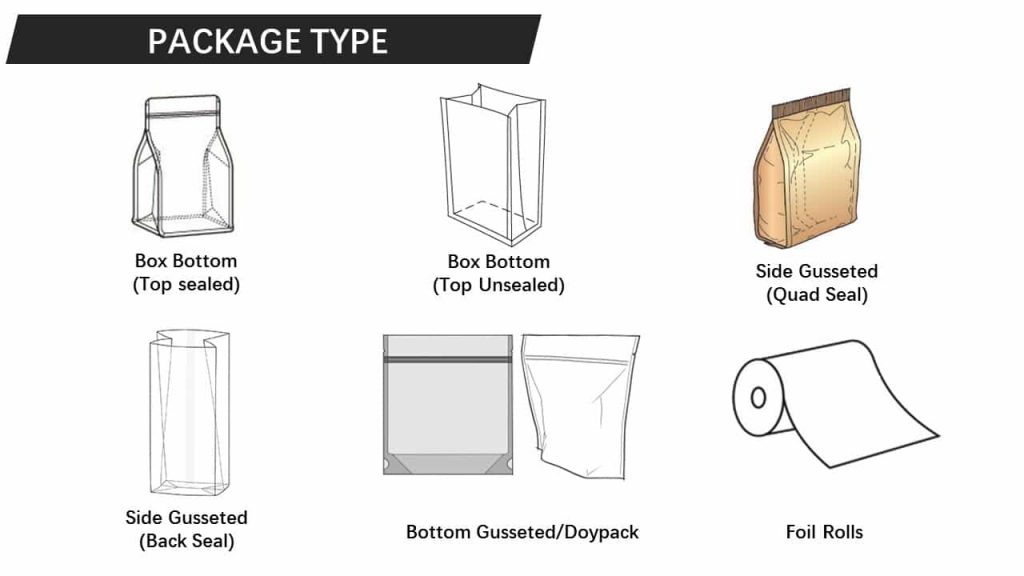

Based on the properties presented by these compostable foil materials, we are able to provide various of package types, including roll foils, bottom gusseted bag/doypack, Side gusseted quad seal pouch, flat bottom pouch with zipper. You are going to get a better understanding with below picture, and you are welcome to reach us for further discussion if you need further assistance.

Applications

Now, these eco-friendly biodegradable foil materials are extending to more and more products. The properties are enough for the package of many products, the biggest issue is higher cost than traditional fossil plastics based materials. Sincerely, we hope the cost for compostable film materials will go lower and lower as the scale becomes larger and larger.

Catalog

You may find our catalog for compostable standing pouch packages here.

RFQ and Free Samples

We are much glad to provide free samples for your further study as long as you are willing to afford the courier cost, and please get in contact with us for RFQ and Sample delivery.

Email: office@valuepackaging.cn

Whatsapp: +86 159 6981 3136

Company Website: www.valuepackaging.cn