Aluminum foil laminate refers to the multilayer film foil that container the thin aluminum sheet inside, that can be further processed into kinds of forms of package, like flat pouch, bottom gusseted standup pouch, quad seal standup pouch, flat bottom pouch, and rollstock foils, for many products. So, in this post, we will come closer to the aluminum foil lamiante, for your reference.

Aluminum foil

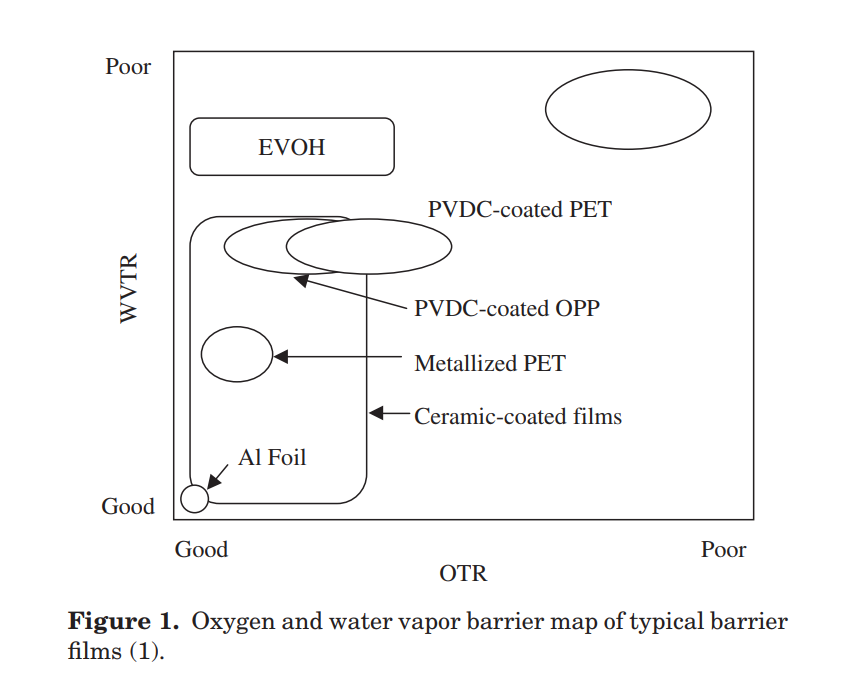

Aluminum foil is thin sheet of aluminum metal, with 7 microns thickness the most used in flexible packaging areas. It is considered the best barrier property against moisture and oxygen among all the barrier film materials in flexible package, with graphic as below.

So when the customers is looking for film foils with excellent barier performance, aluminum foil should be considered. However, with below properties, it means the aluminum foil can not be used for final package alone.

- Easy to crack under outside force (should get it protected on both sides.)

- Easy to wrinkle under crumple pressure, in some cases, tiny holes may appear. ( should get it protected on both sides )

- No seal property (Should be laminated with another sealing layer)

so it will have to come to multilayer laminate

Multilayer Foil Laminate

An integrated foil laminate should consist the below function layers

- Outside print substrate (PET film tops over than other film materials)

- Middle support layer or barrier layer (Aluminum foil)

- Reinforced layer if needed (for example, anti-puncture resistance for the final package)

- Inner sealing layer

so, in actually application, considering the cost and performance, the below structures are the most used regarding aluminum foil laminate.

- PET/AL/LDPE

- PET/AL/PET/LDPE

- PET/AL/PA/LDPE

The property for each item tops over the previous item, and also the price increases accordingly, so the structure will have to be carefully selected against the customer need and cost considerations. We will share more of our experience in future posts.