Standup pouch packages are always printed with attractive artwork, which of course, improve the products sales, and also strengthen the manufacturer branding in consumer impression.

To get the best print effect for the final packages, some customers may wonder, how is the standup pouch package printed?

Based on the current available printing techniques, usually the standup pouch package can be printed in 3 methods

- Flexo print

- Gravure print

- Digital print

Flexo print is environmental friendly, however not able to realize the print as vivid as gravure print, and digital print is of so much higher cost that most manufacturers are not able to afford for their products, so in china, most of the standup pouch packages are realized by gravure printing.

How does that work? Look below.

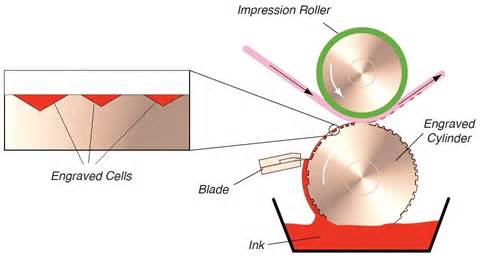

Above is the graphic that shows the theory of gravure print operation. The plastic film substrate goes through the gap between engraved cylinder and the impression roller, and the ink held in the engraved cells of the print cylinder will be transferred to the plastic film substrate.

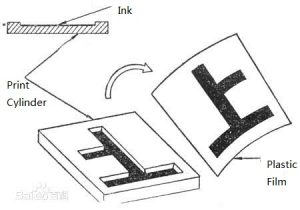

The artwork design will have to be engraved on the print cylinder, with so many tiny cells that is intended to hold ink, so when the ink printed onto the plastic film substrate, the actual text is reverse with the cylinder image.

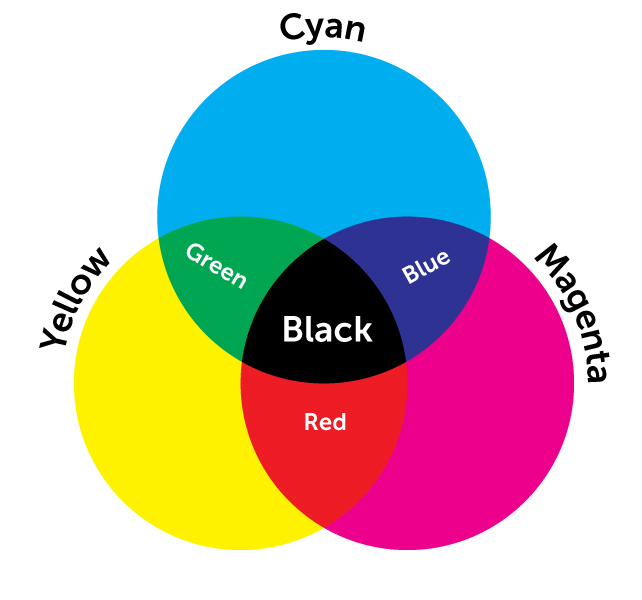

However, the colors of the artwork design can not come from color spot accumulation. The colors can only be formed by CMYK basic colors + spot colors

So, given any artwork design, it will have to need a set of cylinders to realize the print process. (The exact number of cylinders needed will have to be decided against your artwork)

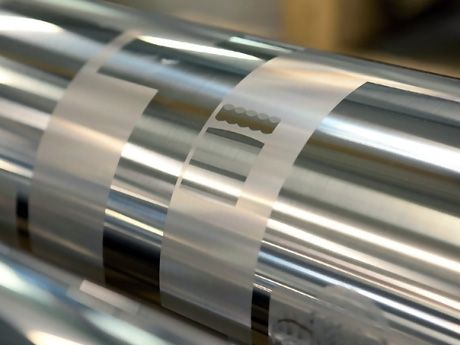

We will review your artwork, and make the layout on the cylinder, and when the cylinders are ready, we can print on our gravure print machines.

Watch video for print process

Contact me

I am looking for zipperlock printing company

Ok