In previous post,we explained how to calculate the cost of print cylinders, the most important factor for the cost of a print cylinder is the dimension. Small print cylinders may only cost USD 30~60 per color, that is a very big savings if the customer just start up their business and would like to have a test in the martket with their logo printed packages.

Of course, we are willing to help our customers to reduce the cost, and at the same time, ensure the quality meet our customer expect. so, in this post, we are going to share some of the cases we have done when we choose to print the customer’s order with small print cylinders. Hope it be helpful.

Usually, small print cylinders are mainly running on the small print machine, that are mainly developed in the 1990s and the early years of 2000s. As this print press is of lower cost, so when the print factories started to spring up when china starts to produce for all the world, and really make itself into a world histroy, most bosses choose to installed these small print press, which would allow the factory to make profits soonest and cover the cost. This small print press also exist in our factory, as below picture.

And nowadays, with the quick develpment of the print presses, more adanced and high speed machines are launched into the market, which is able to present better control, higher speed, higher produce efficiency, etc, more and more factories bring these machines into their manufacture plant, including our factory.

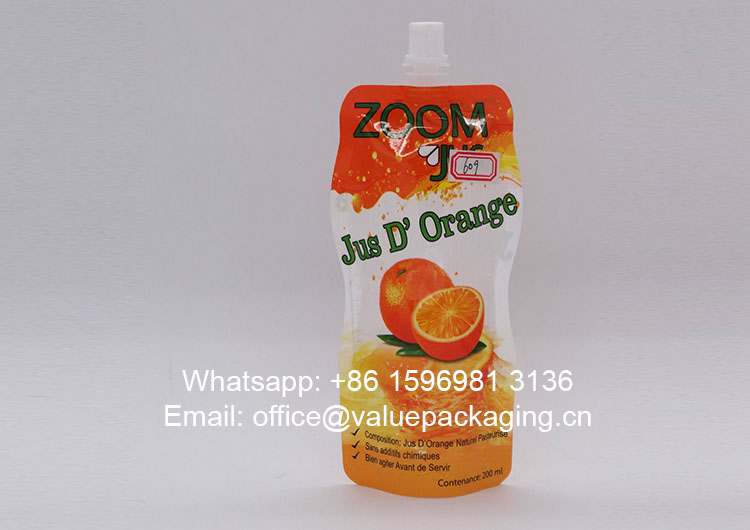

However, we still print some of the customers’ order with the small print press. Sometimes, with quite good print quality, as below standing spout doypack for 200ml juice produced for our Africa customers.

You can check the stunning print effect on the details of the orange, it is exact, accurate and sharp vivid.

Acutally, for the small package which are intended for 5~500grams products, most of the artwork designs can be printed with small print cylinders.However, there are two main drawbacks when the order is printed this way.

- Lower output efficiency. The small print cylinders are mainly running on the print press with maximum running speed 120 meters per minutes, that is quite low compared with newly launched print press with 250~300 meters/minute, and furthre more, the limited width of the small print cylinders will not be able to allow multiple layout of artwork onto the cylinders, that is obviously only half or even one third of large print cylinders.

- Easy to cause print defects.

Some cases with print defects

Bad color overlapping

You can see the outline of the circle surroundings, there is bad overlapping for the colors, this defect happens mainly because of the bad control of the color overlapping system on the outdated print press. Normally, there are some tolerance for the color overlapping, however this should not be visible to the naked eye, otherwise it can only be taken as print defects.

Unsolid Print

The below picture shows some ink spots within the chinese characters are missing, and cause the character not so solid.

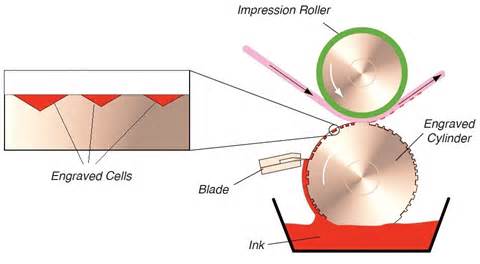

This defect happens because the print press is running as lower speed, so the period for the engraved cells exposed in the air will be relatively longer than that of running at higher speed. So, the ink in the engraved cells may be dried in part, and that influence the ink re-filling when the surface of print cylinders runs into the ink tank. The ink in the engraved cells becomes less and less, and finally achieve the unsolid print effect.

Print defects on shallow grey

Shallow grey is difficult to print in flexible packaging

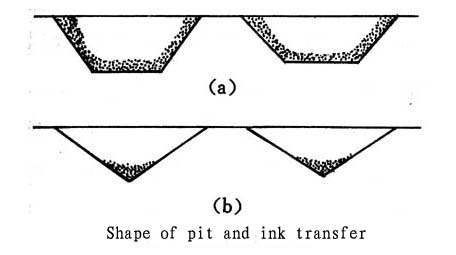

The shallow grey is realized with gradual different deepths of the engaved cells on the cylinder, with deeper cells carrying more inks which is intended to print deep grey, and shallower cells to print shallow grey.

So, the shallower for the cells, the ink is easier to be dried, so a higher print speed is much helpful in printing grey colors. If the customer insist to print this color with small print cylinders, then this print defect may happen.

Video Explanation

You may watch the video explanation for further understanding.

Ok, we come to the end of this post. Sincerely hope it will be of help for you. We indeed like to reduce the cost for our customers, however, this should be based on the final quality meeting the customer expect. So, anyway, do not just go to lower cost if you want to keep a good quality.