As a trust-worthy flexible converter, we would love to share with you a fantastic poly sachet intended for 180 grams of cassava starch. This polybag largely helps our customer build their powerful branding, and indeed it increased product sales by 20% in the Chinese market in 2023. We make the best use of the packaging film materials with human food certificated in the market, and finish this gorgeous package.

In this post, we will explain more about the film materials adopted for this cassava starch poly sachet.

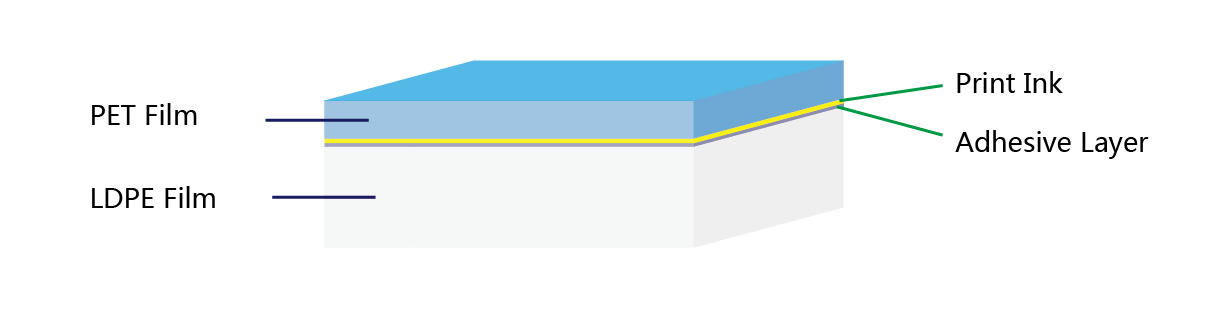

Laminated Foil Materials

As shown in the below graphic, the foil structure is PET/LDPE. It is a reinforced structure with excellent properties for cassava starch packages.

- PET film, works on the outside layer as a superior print substrate and presents product information in a vivid way.

- LDPE film, works as the inner sealing layer, to achieve a strong pouch.

Then, Let’s get a more understanding of each substrate film.

PET film

PET film, sometimes BOPET film, is one of the most commonly used print substrates in flexible packaging areas. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality, and also provide great mechanical strength to the final package.

LDPE film

LDPE means low-density polyethylene film, which is the most used inner sealing layer for the bag. It can provide enough sealing strength and airtight properties for the final packages. It is the most used inner sealing layer for the cassava starch bag.

LDPE is able to provide enough sealing strength and airtight properties for the final packages. It also has good moisture resistance and can effectively block the outside moisture to protect cassava starch quality.

Although the LDPE layer has lower tensile strength than the PET layer, the LDPE layer is better than PET film in flexibility, so when the bag is subjected to a small tensile force, the bag can have a certain degree of tensile deformation without breaking immediately so that the bag can adapt to a certain range of external force changes.

Thickness

In the picture below, we can see the overall thickness of this pouch is 0.228 mm, which equals 114 microns for this laminated foil. It should work so well for 180 grams of cassava starch.

So, how do these films perform when it is intended for the cassava starch bag? Will it protect the cassava starch?

Great Mechanical Property

The package will protect cassava starch when in transit and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, the package will never be allowed to break. Can you imagine the cassava starch spread all over the floor when the bag is damaged?

This reinforced laminated foil is achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, on customer requirements, and you may check the exact values of this foil material in the Technical Date Sheet part of this post.

In our daily QC work, there is a more reliable method to check if the bag strength is enough to meet the final requirements of various customers. We perform a drop test against each order, of course, the standard for this drop test should be decided against customer needs.

Here, we performed a drop test against 280 grams of cassava starch poly sachet, and it did not break after 3 drops from 1.6 meters high. Just watch the video for further understanding.

Barrier Performance

The cassava starch will have to be well protected from moisture. The moisture barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) in our laboratory conditions. With Mocon test equipment in our plant, we are able to get close understanding on the properties.

The typical values of WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) of this laminated foil PET12/LDPE100 are listed in the table below.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 9.84 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 36.2 |

Of course, some customers may be seeking for a foil laminate with better blocking performance for their cassava powder, and here are some available items for your reference.

- PET/VMPET/LDPE

- PET/AlOx-PET/LDPE

Technical Data Sheet of 180-gram cassava starch bag

Here, we attach the specification sheet of the 180g cassava starch poly sachet bag based on film material PET/LDPE.

More tests are included in this specification sheet with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to learn more about this PET/LDPE laminated foil, you can read it here.

More Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages which leads to a more eco-friendly activity of the business. Upon the recent investigation of the nut market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Compostable Packaging Materials

The compostable packages are based on plant-based fibers like cellulose, or bio-mass like corn starch, cassava, or sugarcane. The resins derived from these resources are usually named bio-polymer, which can break down into inorganic elements under the functions of algae, bacteria, and other microorganisms.

At present, we have developed several compostable foil materials that can be intended for powder food, as shown in the list below.

- Cellulose/PLA+PBAT Film

- Cellulose/Metallized Cellulose/PLA+PBAT Film

- Metallized Paper/Cellulose/PLA+PBAT Film

- Kraft Paper/Metallized Cellulose/PLA+PBAT Film

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, fully recyclable materials sachets, and rolls are flooding the market for lightweight product packages in the market at much lower prices.

Compared with the high cost of compostable foil materials, fully recyclable materials sachets, and rolls are flooding the market for lightweight product packages in the market at much lower prices. Mono materials packages mean each layer of the multi-layer foil is made of the same resin, which can be easily processed in the human recycling system and reused for other applications. This recyclable materials sachet largely reduces the rate of plastic polymer film packages ending in landfills.

That’s all for now. If you have any questions, feel free to contact us. Enjoy your time!