Antioxidants have played an important role in individuals’ daily lives recently, which could effectively avoid oxidation of objects in the respects of foods, medicines, cosmetics, and so on. As green materials, natural antioxidants not only promise the security of the objects but also achieve the ideal antioxidant effect.

Utilizing a folded gusset at the bottom to hold extra products, the standup pouch presents a better display when they stand on the goods shelves. Therefore, it would require the foil materials to be strong and durable, to ensure the products are well protected during the filling, transit, and distribution process.

To reach the antioxidant effect and store the antioxidants effectively, generally speaking, the foil material of the spout pouch for the natural antioxidants is PET/LDPE.

Based on a flexible combination of various polymer film materials, the foil materials are able to provide excellent barrier properties, protecting theantioxidants from air, moisture, and light. Furthermore, a creative artwork design can be printed on all sides of the standup pouch, including all the information for branding and sale, which makes the final package more attractive to consumers.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the packaging film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We are devoted to creating story-telling standup screw cap bags for natural antioxidants that increase product sales and establish a good brand image.

In this post, we will analyze the exact foil materials of this 450ml natural antioxidant standup bag, hoping it could serve as a reference for your products.

Ok, let’s get into the details of this standup screw cap spout bag.

Packaging Foil Materials

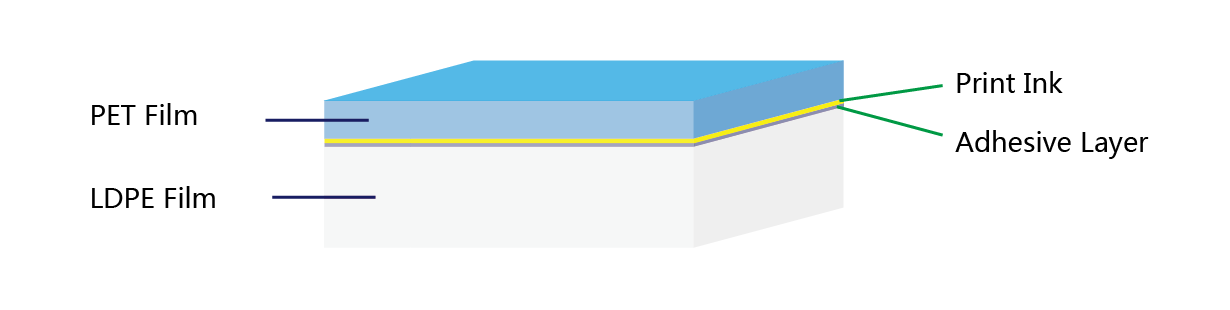

The figure below shows the composition structure of this laminated foil material used to convert this standup natural antioxidant bag.

It consists of double layers, with the outside 12 microns of PET film, working as the print substrate film, and the LDPE film working as the inner sealing layer. The thickness LDPE film should be adjusted to suit the requirements of 450ml natural antioxidants.

Next, let’s get into a deeper understanding of each substrate film material.

Physical properties:

PET Film

Physical Properties: PET Film, is one of the most commonly used printing substrates in flexible packaging sachets. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality, and also provide great mechanical strength to the final package.

The most commonly used thickness of PET film applied in the flexible packaging industry is 12 microns, which equals 0.48 gauge. So whenever you see PET12 or 0.48 g PET, you will know they mean the same thing.

Uses of PET Film: PET film has many uses, including:

- Packaging: PET film is used in containers for food and liquids, as well as in flexible packaging.

- Manufacturing: PET film is used in thermoforming.

- Engineering: PET film is combined with glass fiber to create engineering resins.

- Films: PET film is used for antimicrobial and insulation films, surface protection, hard-coats films, protective films, and printable films.

- Labels: PET film is used for labeling and labeling face-stocks.

- Security: PET film is used for security and tamper-evident films.

- Display signs: PET film can be used to make outdoor display signs for advertising.

- ID cards: PET film can be used to print business ID cards.

Physical Properties: LDPE Film means low-density polyethylene film, which is the most used inner sealing layer for standing natural antioxidants. LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. Most importantly, LDPE membrane can be modified against the requirement of specific products, and finalize the package with great seal strength and protection. The thickness of the LDPE membrane film will be decided against the particular application.

It is made up of dimethyl terephthalate (DMT) and ethylene glycol and has many desirable properties, including:

- Crystal clear

- High tensile strength

- Low moisture absorption

- Strong dimensional stability

- Maintains physical properties in extreme temperatures

- UV resistance

- Optical clarity

- Good gas barrier

- Excellent electrical properties

- High gloss

Chemical properties

As the inner layer, directly contacts the products, LDPE Film is known for its corrosion resistance, which could ensure the foil materials will not cause a chemical reaction. Some antioxidants may have certain acidity and alkalines. Therefore, we’d better choose foil materials that have corrosion resistance.

Besides, stability is also a crucial factor for the election of the foil materials. The foil materials themselves should keep stable during the process of storing and utilizing, not releasing harmful substances or odors.

If you have more demanding requirements for the corrosion resistance and stability property, you are advised to contact us. We are very professional in this realm to help you meet your needs.

So, how does this foil structure perform when it is intended for standup laundry detergent bags? Will it break during the transit? We made some tests for its basic properties.

Great Standup Effect

Through the below video, you may learn the standing effect when 450ml of natural antioxidants are filled into a spout bag based on this laminated foil PET12/LDPE115.

To be honest, PET/LDPE is not the best choice. These two layers of foil material are relatively thin and stiff. In order to enable the package to feel more durable and soft, you are advised to use the materials PET/ PA/PE, which is the most perfect structure in the recent natural antioxidants market.

The next video introduces the difference between PA/PE and PET/PA/PE structure. By the way, it may increase the cost. You could decide to use which material according to your company’s situation. If you have any questions or want to have further information about this structure, do not hesitate to consult us.

Mechanical Property

The spout package will protect the natural antioxidant product during filling, transit, and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, the spout package will never be allowed to break. Can you ever imagine the leaked laundry detergent contaminating the cartons or the floor?

In the experiment, strictly follow the relevant strands and drop the packaging bag containing 450ml items freely from different heights. Serious measures are taken in our QC system, to assure each order is finalized with the expected result.

Here, we are going to fill 500ml liquid detergent into this bag, perform the drop test from 1.6 meters high, 3 times, and check if it breaks.

Barrier Performance

Generally, the essential formulas of a natural antioxidant should include but not be limited to the list below.

Vitamin Category

- Vitamin C: Widely exists in fruits and vegetables, which could protect the cells from antioxidation.

- Vitamin E: Commonly found in nuts, plant oil, green vegetables, and so on, which have the function of antioxidation.

Polyphenol Compounds

- Flavonoids: Present in fruits, vegetables, tea, etc. It has various biological activities such as antioxidation and anti-inflammation.

- Anthocyanins: Rich in blueberries, having strong antioxidant capacity.

- Tea Polyphenols: Mainly exist in tea.

Based on its formulas, natural antioxidants need to avoid the following situations during storage and use:

- High temperature

- Light

- Oxygen

- Metal ions

- Humidity

Upon experience, all the bags and sachets for natural antioxidants should avoid these situations to ensure the formulas work as expected. Because high temperature and strong light will decrease the antioxidation effects, and some metal ions may increase the speed of oxidation. Natural antioxidant products will be kept away from these situation to stay function-active as long as possible.

Furthermore, WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, to decide if this spout doypack is finally meeting the requirements of each customer.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 9.0 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 34.28.5 |

Technical Data Sheet of 450ml Natural Antioxidants standup pouch

Here, we attach the specification sheet of this 1800ml laundry detergent liquids sachet based on foil laminate PET12/LDPE115.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to get a further understanding of this PET/LDPE laminated foil, you may just read it here.

More Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages which leads to a more eco-friendly activity of the business. Upon the recent investigation of the detergent market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Compostable Packaging Materials

Some of our customers are trying to replace their traditional film materials with compostable items. You can see the roll in below picture is actually made of 100% compostable materials, for one of our customers in New Zealand.

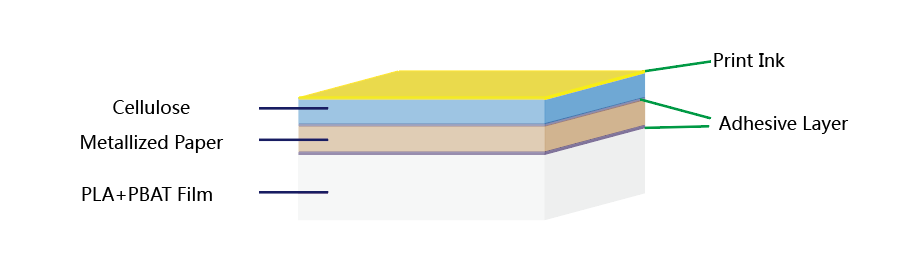

The below graphic shows clearly the foil structure for this laminated compostable foil.

The artwork is printed reversely on the inner side of plant-based cellulose film, with another layer of metalized cellulose working as the light-shielding and barrier layer, and PLA+PBAT biodegradable film works as the inner sealing layer.

However, it didn’t meet the customer’s expectations.

As explained previously, it is crucial for the laminated foil to protect the formulas of the liquid detergent in the sachet. However, for this compostable foil, the ingredients of the liquid detergent can easily penetrate into the PLA+PBAT film, which is in full touch with the liquids all the time. When a certain amount of ingredients passes through the PLA+PBAT film, it will inevitably damage the adhesive between PLA+PBAT film and metalized cellulose, which leads to the delamination of this foil.

For this customer, the compostable foil fails to meet his requirements.

Based on this situation, the compostable foil materials will never be allowed to hold products in large volumes, like 1 liter, 2 liters, or 3 liters. That is different from the traditional polymer film materials explained above. You may us for further ideas if you need them.

Fully Recyclable Mono Materials

Some of our customers are actually moving to fully recyclable mono materials bags which are well-resistant to the formulas of liquid detergent. They can work well for liquid detergent up to 250ml, as the mechanical properties of this recyclable bag are so far behind the tradition materials bag.

Now it’s the end. You are welcome to reach us if you have any questions regarding juice pouches. Have a nice day.

GOOD PACKAGE!