As is shown in the picture, such standing bags are favored by customers in the food market. The material of the package is MatteBOPP18/VMPET12/LDPE50. It has excellent performance. Firstly, the good barrier properties can effectively keep air, water, and light at bay. As a result, the corn starch can stay dry and fresh for a long while, which helps to avoid deterioration and the loss of nutrients. Secondly, this material is tough and sturdy. It can endure certain amounts of pressure and impacts during transportation and storage. Moreover, it is not easily broken, thus offering dependable protection for the product.

The gorgeous pattern can be printed on the packaging, including all the information for branding and sale.It makes the final package more attractive to consumers.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the packaging film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

Our service tenet is to make every bag with heart. These bags can promote product sales and build a good brand image. In this article, we will analyze the specific materials for the 100-gram standing pouches packaging of coconut, hoping that it can reference your products.

Now, let’s get into the details of this 100-gr coconut powder stand-up doypack.

Packaging Foil Materials

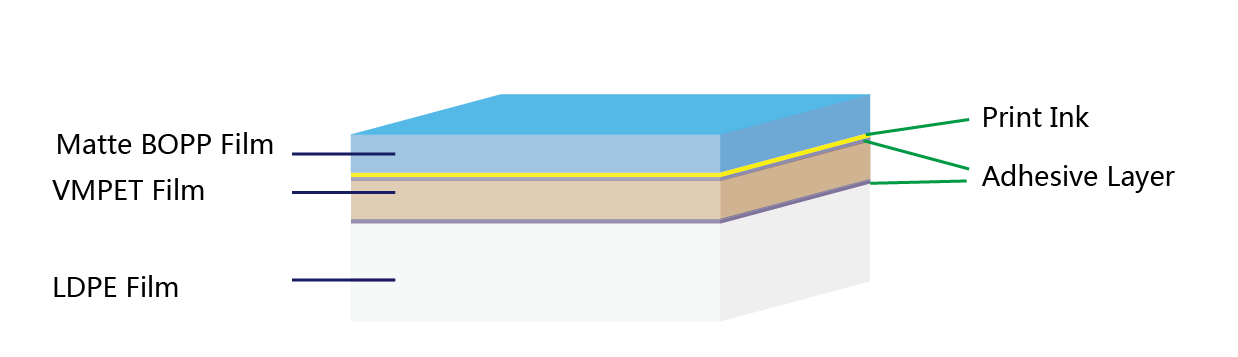

This foil material is a reinforced structure with excellent properties for corn starch packages. The foil structure is MatteBOPP/VMPET/LDPE, with a graphic as below.

The film material of the corn starch package is made of three layers. The printing layer is Matte BOPP film.VMPET, as the middle layer, plays a good role in providing a barrier effect. and the LDPE film works as the inner sealing layer. The thickness of the LDPE film should be adjusted to suit the requirements of a 180-gram cornstarch poly sachet pouch.

Next, we will have a more in-depth discussion regarding each substrate film material.

Matte BOPP Film

Matte BOPP, or matte biaxially oriented polypropylene, is a polymer film with a matte finish that absorbs light instead of reflecting it. With a matte finish effect on the outside, Matte BOPP film is widely used to improve visual effects and add a fashionable touch to the packaging.

VMPET Film

VMPET12, which means vacuum metalized polyester film with a thickness of 12 microns(equal to 0,48 gauge), is the most commonly used aluminum metalized film inflexible packaging field. it has with high barrier performance against moisture vapor and oxygen. The barrier performance will enable your coffee products well-protected from the roaster warehouse to the consumer’s hand in a fine way.

LDPE Film

LDPE (Low-Density Polyethylene) film is a commonly used plastic film. Due to its good flexibility, low-temperature resistance, and chemical stability, it is usually used as the heat-sealing layer in packaging. The LDPE film has relatively high transparency and a certain barrier effect against water vapor. It is widely applied in fields such as food packaging and daily necessities packaging. For example, it is used to package fruits, vegetables, snacks, etc., which can effectively protect products and extend their shelf life.

These 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. Usually, we describe the finished laminate as MatteBOPP18/VMPET12/LDPE50 foil.

Great Standup Effect

Through the following picture. It concerns the 100-gram coconut powder standing pouches. These pouches are made from laminated materials. The materials are Matte BOPP 18, VMPET 12, and LDPE 50. Through this picture, you can get to know about the standing effect of these pouches.

Matte BOPP 18 on the outside provides a matte finish that not only gives an aesthetically pleasing look but also offers a certain degree of rigidity. This layer helps maintain the shape of the bag and contributes to its overall stability.VMPET 12, as the middle layer, provides good barrier properties. It helps in keeping the contents of the bag protected from external factors such as moisture, oxygen, and light. This layer also adds to the structural integrity of the bag, enhancing its ability to stand upright.LDPE 50, as the inner layer, is suitable for heat sealing. It provides flexibility and seals the bag effectively.

The combination of these three layers results in a bag that is both durable and stable. The relatively thick LDPE layer provides a solid base, while the other layers contribute to the overall strength and stiffness of the bag. This enables the bag to stand firmly on various surfaces, making it convenient for display and storage. Whether on store shelves or in warehouses, this packaging bag with its specific material combination shows remarkable standing stability.

Mechanical Property

The foil material of Matte BOPP 18/VMPET 12/LDPE 50 has good mechanical properties. Matte BOPP 18 offers tensile strength and shape stability. VMPET 12 provides stiffness and puncture resistance. LDPE 50 adds flexibility, enabling the bag to endure normal handling, stacking, and transportation without easily getting damaged.

The package structure will protect the sunflower seed product during filling, transit, and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, the food package will never be allowed to break.

The mechanical property of this standup sachet is the top priority in our manufacturing plant. Serious measures are taken in our QC system, to assure each order is finalized with the expected result.

To put it simply, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces.

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, there are certain requirements for the barrier properties of coconut powder packaging. That’s because coconut powder contains a certain amount of fat and sugar. If the barrier properties are poor, moisture can easily enter the packaging bags. After absorbing moisture, the shredded coconut powder will become lumpy, which will affect its taste and quality. Besides, the oils in shredded coconut powder are prone to oxidation. Good barrier properties can slow down the oxidation rate of the oils, thus maintaining the flavor and nutritional value of the shredded coconut powder.

You can easily find out the typical values of the moisture vapor transmission rate and oxygen transmission rate of this multilayer foil MatteBOPP18/VMPET12/LDPE50.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.85 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.2 |

Some customers have a preference for obtaining high-quality packages that possess enhanced barrier properties. In such a situation, the VMPET layer can be substituted with a thin aluminum foil sheet. As a result, certain reinforced foil structures offer improved protection for maintaining the freshness and flavors. The following are some available item structures.

- BOPP/AL/LDPE

- MatteBOPP/Kraft Paper/Al/LDPE

- Kraft Paper/PET/Aluminum/LDPE

Technical Data Sheet of 100 gr coconut powder standup doypack

Here, we attach the specification sheet of this 100-gr coconut powder bag based on foil laminate MatteBOPP18/VMPET12/LDPE50.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

Learn more about this foil laminate on our company website.

More Sustainable Materials Options

As the amount of fossil-chemical polymer materials being discarded into the environment continues to rise, there is now an unprecedented need for sustainable packaging. This shift is driving businesses to adopt more eco-friendly practices. A recent study of the nut market reveals that an increasing number of consumers are more inclined to buy products that demonstrate a commitment to environmental sustainability.

Compostable Packaging Materials

The compostable packages are based on plant-based fibers like cellulose, or bio-mass like corn starch, cassava, or sugarcane. The resins derived from these resources are usually named bio-polymer, which can break down into inorganic elements under the functions of algae, bacteria, and other microorganisms.

At present, we have developed several compostable foil materials that can be intended for coconut powder product, as shown in the list below.

- Cellulose/Metallized Cellulose/PLA+PBAT Film

- Metallized Paper/Cellulose/VMPET/PLA+PBAT Film

- Kraft Paper/Metallized Cellulose/PLA+PBAT Film

Fully Recyclable Mono Materials

Compared with the high cost of compostable foil materials, fully recyclable materials sachets, and rolls are flooding the market for lightweight product packages in the market at much lower prices. Mono materials packages mean each layer of the multi-layer foil is made of the same resin, which can be easily processed in the human recycling system and reused for other applications. This recyclable materials sachet largely reduces the rate of plastic polymer film packages ending in landfills.

Nowadays, we have developed some standup pouches based on single resin film materials, that can be found good application for roasted almond products.

That’s all for now. If you have any questions, feel free to contact us. Enjoy your time!