Different types of packaging bags have greatly improved the convenience of our daily lives. Pillow bags are popular for their unique style and practicality. They are often used in industries such as food because they are very convenient for transportation, placement, and display.

So, what are the materials used to make pillow bags?

Let’s take a deeper look at the details of this pillow bag.

Packaging Foil Materials

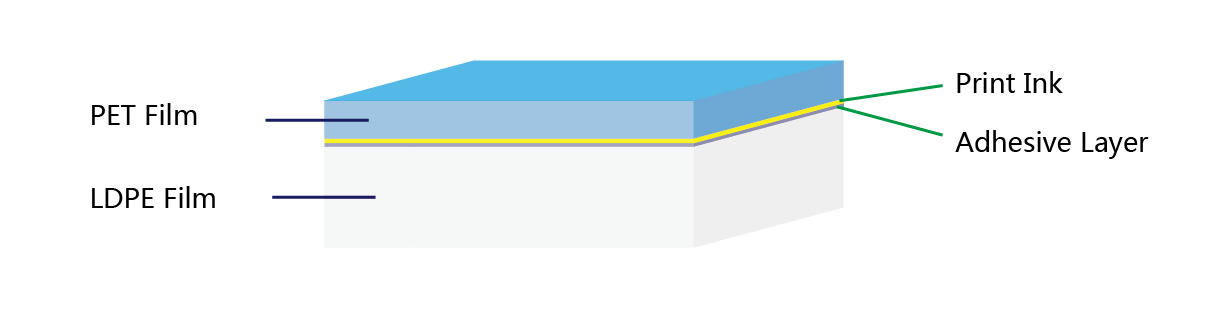

The film material of the sweet potato powder is made of two layers. The printing layer is PET film, and the LDPE film works as the inner sealing layer. The thickness of the LDPE film should be adjusted to suit the requirements of a 400-gram cornstarch poly sachet pouch.

Next, we will talk further about each substrate film material.

PET Film

PET film, sometimes BOPET film, is one of the most commonly used print substrates in flexible packaging areas. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality and provide great mechanical strength to the final package.

LDPE Film

LDPE means low-density polyethylene film, which is the most commonly used inner sealing layer for the bag. It can provide enough sealing strength and airtight properties for the final packages.LDPE film has good flexibility, can be bent at will, is not easy to break, and excellent transparency, and can display the product. Because of this feature, It is popular in the field of food packaging. Like cookies and candy packaging, we can often see the LDPE film figure.

It also has good moisture resistance and can effectively block outside moisture to protect product quality. At the same time, its chemical resistance is also relatively good, and it has a certain tolerance to many common chemical substances. However, LDPE film also has some limitations, such as its relatively low mechanical strength, tensile deformation, and even damage when subjected to large external forces, and its oxygen barrier is not particularly ideal, in some oxygen-sensitive product packaging, it may need to be combined with other materials to improve the barrier performance.

These 2 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. Usually, we describe the finished laminate as PET/LDPE foil.

VMPET Film

However, many customers have relatively high requirements for products. To achieve better barrier properties and ensure the freshness of the products, customers will choose metallized PET to increase the barrier properties.

VMPET film is short for vacuum metallized polyester film, that is achieved under vacuum conditions to deposit a thin layer of aluminum atoms onto the surface of PET (polyester) film substrate, and finally realize a bright metallic film that is widely used in flexible packaging and standup pouch packages.

VMPET has very good barrier properties, which can effectively prevent moisture penetration and block sunlight. For this type of product, it can greatly improve the freshness and dryness of the product. In addition, VMPET has a very good metallic luster. Many customers choose this material not only because of its good barrier properties, but also because of its good price and excellent metallic luster, which can greatly show the texture of the product packaging.

Thickness

As you can see from the picture below, the overall thickness of this 4-sided sealed pouch is 0.209 mm, which equals 209 microns for this laminated foil.

However, many customers have higher requirements for their products. In order to better barrier properties and ensure the freshness of their products, customers will choose aluminum oxide film to increase barrier properties.

Mechanical Property

PET/LDPE composite packaging bag has good tensile strength. The PET layer provides a high tensile strength and modulus. so that the bag is not easily to be pulled broken. When it is subjected to a certain tensile force. For example, when handling bags filled with heavy items, the PET layer can withstand the tension generated by the weight of the item, preventing the bag from tearing on the handle or other stress areas.

The LDPE layer has lower tensile strength than the PET layer, but its presence increases the overall flexibility of the bag. This means that when subjected to a small tensile force, the bag can have a certain degree of tensile deformation without breaking immediately so that the bag can adapt to a certain range of external force changes

We put the mechanical property of this 350-gram corn starch sachet pouch on our top priority in our manufacturing plant. Serious measures are taken in our QC system to ensure each order is finalized with the expected result.

To put it simply, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces.

Sure, there are reinforced foil structures available for more robust packages

- Kraft Paper/LDPE

- PET/VMPET/LDPE

- PET/PA/LDPE

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The table below shows the typical value of the WVTR and OTR of the most common substrate films in flexible packaging.

Based on our experience, PET/LDPE foil laminate will be able to meet most of the requirements for 400 gram sweet potato powder pouch. WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the table below.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.85 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 1.2 |

Technical Data Sheet of 400 grams sweet potato powder bag

Here, we attach the specification sheet of this 400-gram sweet potato powder bag based on foil laminate PET/LDPE.

More tests are included in this specification sheet, with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

Learn more about this foil laminate on our company website.

It is my great honor to share this with you. I will update you with more details about VMPET stand-up bag next time.

Thank you very much. If you are interested, please feel free to contact me. Enjoy!