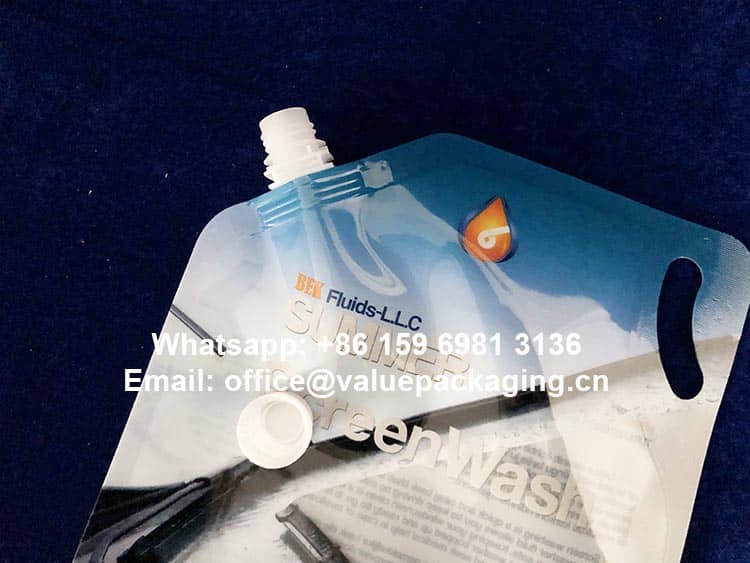

Standing doypack pouches are becoming more and more favored in the consumer market for windshield washer fluid products. It not only provides a better user experience when consumers try to refill their automobile with fresh cleaning chemicals, but also reduces the plastic material used for each individually filled bag.

Furthermore, attractive artwork design can be printed onto the standing bag with the highest standard of color consistency, which appeals to consumers in a feeling-good way. So, more and more packers are now seeking to fill windscreeen products into these standing screw cap bags.

Our company is a trustworthy manufacturer of standing spout doypacks located in Qingdao, China, for more than 10 years, and has been providing great standing bags for many brands and packers around the world, with near-zero-failure supplies in the long term. Here we are going to share our experience on how to choose the filling machinery to finalize the windshield washer fluids into a standing doypack.

Filling from the plastic spout or the top opening

One fundamental thing before talking about the machinery to fill the screw cap bag is to understand where to fill the washing liquids. As the plastic spout and screw cap system enables the standup bag to provide better re-sealing experience for the consumers, so the washing liquids can be filled from the plastic spout alternatively.

Filling from the corner spout

The doypack is held tightly on the rotatory tray, with the channel of the plastic spout trapped on the slots. The filling nozzle will be lowered into the inside of the package, and guide the washer fluids to the bag.

The advantage of filling products from this plastic spout is the great integration for the final package, as the doypack is finalized with all edges well sealed, and the closure is separately supplied to the customer with the doypacks.

After fluids filled, the closure will be screwed onto the spout, with counterfeit purpose.

Filling from top opening

The top edge will be left open when the standup pouch is supplied to the customer, and when products are going to be filled from the top opening, the efficiency can be largely improved. The top opening can accommodate a filling nozzle with a significantly larger inner diameter, allowing for a greater volume to be filled within a certain time frame.

When we figure out how to fill the doypack, then we can go on with our discussion on how to choose an acceptable and money-making filling machine to fill the windscreen washing chemicals into the standing spout doypack package. As there are various filling machineries in the market, we are going to share some of our experience and reliable machinery for your reference. Hope we can assist you in getting the ideal filling machinery for your long-term business.

Cost

Filling machinery at different levels comes into the market, of course, with quite different prices, ranging from USD 800 to USD 35,000 for most machinery.

Output Efficiency

Output efficiency matters so much if you want your business to come into a prosperous future. Now, a great filling line can fill 2,000 bags of windscreen cleaning chemicals with a 2-litre product volume. Of course, not every customer will actually need an automatic filling machine with this high speed, and there are other options available that are designed to help the customer reach their full business potential.

Durable and Long-term Working Reliability

The main parts of the filling machinery is made of stainless steel, to prevent the alkaline corrossion from the washing chemicals. The sealing rubber is made of chemical resistant material, which can last for a longer time without any mainenance after installed.

Changeover Time

Easy Maintenance

A long-term working filling line can only reach its maximum potential and working efficiently when it is well maintained. However, try to find a filling machinery with easy and simple maintenance.

Lower-cost filling line for market test or sample produce

If you want to buy a low-cost filler to teat your market, then several hundreds of USD will do when you get it supplied from China. Here, we will share one commonly-used filler for our customers.

One person operating Semi-automatic Filler for Small Business or Startup

This is a trust-worthy filling machine to achieve best ever efficiency based on one person operation. It would be an ideal filler if your business stays small and can not compete with the large pioneers. The machine price is about USD 4,000~6,000, which can give you another edge in the marketing competition.

Automatic Rotary Filler With Maximized Efficiency

The most common system for filling windshield washer fluids into spout pouches with maximized high speed is rotary filling. There are many holding slots on the turntable. Spout doypack can be continuously fed into the tray, held tightly on the slots for the next filling and screw operations. Finally, the filled doypacks will be discharged at the ending and ready for another round of filling.

With a refined adjustment, this rotary filler can achieve up to 2,000 packs of 2-liter capacity filling per hour. You are advised to watch the filling operation of this fantastic filler in the video below.

Ok, here we come to the end. At Tongli Packaging, we are always doing our best to be of the best assistance for the business of our customers with superior quality doypacks, and durable filling machinery supplier by our partners. You can contact our team for further ideas when you have any questions.