More and more coffee roasters are looking for sustainable packages for their coffee products, with options like recyclable, biodegradable, and compostable. Some roasters may be more interested in compostable coffee packages, as these packages will break down into inorganic materials like CO2 and water, leaving no harm to the environment. During their investigation into compostable packaging, some may come into contact with metallized PLA (Polylactic Acid) coffee packaging, which may confuse some of those who do not have enough understanding of the film materials, conversion craftsmanship, and its properties.

As a reliable, flexible converter located in Qingdao, China, we will further analyze this metallized PLA coffee packaging to see whether it meets the particular requirements for your coffee products.

What is PLA (Polylactide)

Polylactide, PLA, is a biodegradable thermoplastic polymer derived from natural lactic acid from corn, maize, or sugarcane. Because of its bioresorbable and biocompatible properties in the human body, it has been widely studied for use in medical applications. Along with the continuous reduction in production costs, PLA has been extended to packaging applications for a broader array of products, such as coffee, nutrition, milk powder, tablets, handwash, etc.

PLA is certified as a compostable polymer according to ASTM D6400 and European Standard EN13432 by the main certifying entities in the international market. Unlike cellophane film, PLA can be composted in 180 days in a commercial composting facility, but it would take much longer and be more difficult to compost in soil conditions.

The film roll in the above picture, resembling PET (Polyethylene terephthalate) film, is BOPLA (Biaxially oriented Polylactide) film. After biaxial orientation, the film is finished with high clarity, great printability, and excellent mechanical properties. However, the BOPLA film is too rigid and stiff, and when it is applied in the flexible packaging field, it may be too crisp and fragile, as you can learn about the nosity crips of BOPLA through the video below.

So, blends of PLA with other biopolymers are researched to improve sealing strength, burst strength, tear strength, and softness. PLA+PBAT is the most successful biopolymer blend, and it is widely used in the commercial compostable film field.

PBAT is short for polybutylene adipate terephthalate, which is marketed as a biodegradable copolymer with BASF’s ecoflex showing 90% degradation after 80 days in testing. The flexibility and toughness of PBAT make it ideal to be blended with other biopolymer. Hence, the blends of PLA+PBAT are developed and can be blown into a tublar film with improved properties, to make it an ideal inner sealing layer for compostable coffee bags.

However, under the influence of PBAT, the finished blown film will never be high transparent, but semi-opaque as the picture below.

How to call it? PLA or PLA+PBAT film?

Along with the quick update and development of compostable materials in the market, there is still no definite naming of this biodegradable and compostable film. Some people may just use PLA to mean BOPLA film; others may refer to the blended PLA+PBAT film. Upon our understanding, it is better to trace back to the film’s polymer.

Hence, we call the transparent film BOPLA film and the semi-opaque blended film PLA+PBAT film.

But, why metallized?

Vacuum Metallized Craftsmanship

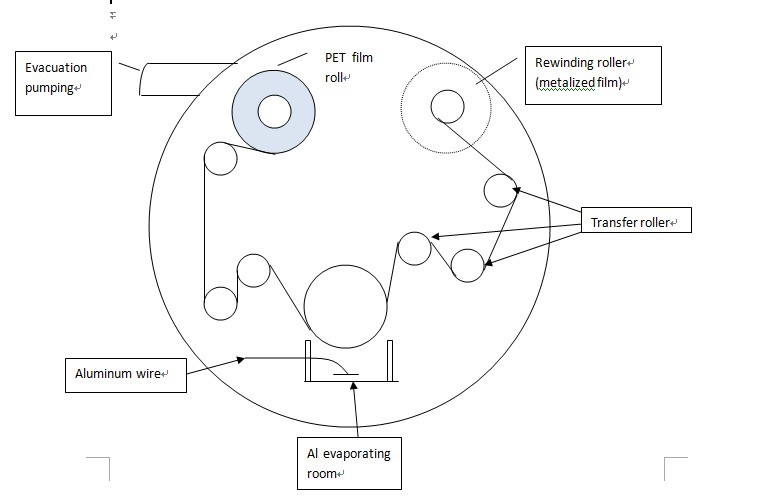

Vacuum metallizing is a physical vapor-deposition process that applies a metal coating onto the surface of a substrate film by thermal evaporation of aluminum under vacuum conditions. As you can observe from the figure below, aluminum wire is evaporated in the evaporating room, and when the film passes through the top of the room, the vapor deposits onto the surface. This is the most cost-effective method to increase the barrier properties of a substrate film in the flexible packaging field.

This also happens to BOPLA and PLA+PBAT Films. Based on the oxygen permeation test with Mocon OX-TRAN 2/22 Series—2-Cell tester in our laboratory conditions, we find that these two films can never be used alone as the fragrance protective layer in the coffee packaging field. Also, the water vapor transmission rates are tested against these two films with Mocon AQUATRAN 3 Analyzer, and we find their performance does not fulfill the requirements of coffee packaging. We include the values of OTR (short for oxygen transmission rate) and WVTR (short for water vapor transmission rate) in the table below, for your reference.

| Items | Standard | BOPLA Film 40 μm | PLA+PBAT Film 40 μm |

| WVTR @38℃, 90% RH cc/m2/24hr | ASTM E 96 | 43 | 47.2 |

| OTR @23℃, 0% RH cc/m2/24hr | ASTM D 3985 | 382 | 515 |

So, vacuum metallization craftsmanship is applied to BOPLA film to enhance the barrier performance against oxygen and moisture vapor. Due to the limits of the easy-to-tensile property and low surface tension of PLA+PBAT film, vacuum metallization can not be achieved on its surface.

Metallized BOPLA Film and its Application

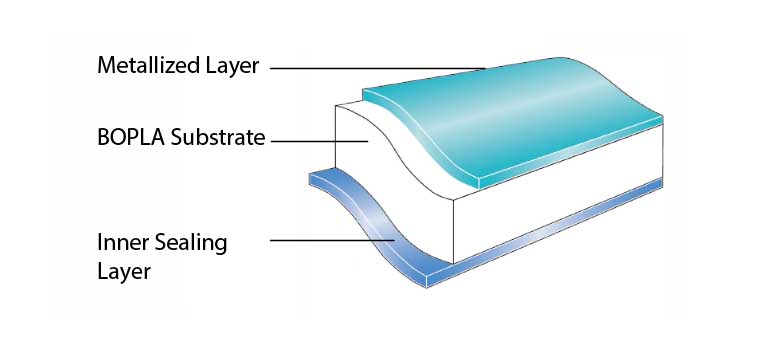

When the vacuum metallization is applied to the BOPLA film, the aluminum metallized layer is on the outside, with an inner sealing layer to achieve the integrated package.

It can be used alone for candy, food, gifts, and snacks. However, the BOPLA film is too rigid and hard and may not be flexible and strong enough to support products weighing more than 250 grams.

So, when it comes to the versatility of coffee packaging, VMBOPLA film itself can not fulfill the requirement. Multilayer foil laminate has to be considered to finalize effective coffee packaging.

Multilayer compostable coffee packaging

Some multilayer foil laminates are developed to achieve compostable coffee packaging. When BOPLA film works as the inner sealing layer, the coffee bag may be too rigid to meet the protection and flexible requirements of ground and whole bean coffee. You may get a sufficient understanding through the video below.

When the soft and flexible PLA+PBAT film works as the inner sealing layer, the flexibility and strength can be obtained to make a great protective coffee packaging as good as that of a traditional plastic coffee bag.

So, in reality, the metallized PLA coffee bag may be achieved based on a metallized substrate and PLA+PBAT lining, with some commercial items available, as below.

- Cellophane/Metallized Cellulose/PLA+PBAT

- K-Cellulose/Metallized Cellulose/PLA+PBAT

- Metallized Paper/Metallized Cellulose/PLA+PBAT

- (PVDC Coated) Cellulose/Metallized Paper/PLA+PBAT

Based on our experience, the metallized PLA coffee bag can provide good protection for up to 1 kilogram of coffee. You may read on to figure out more details on the drop test of the 1 kg compostable PLA film pouch below

At Tongli Packaging, we offer various compostable coffee bags that comply with ASTM D-6868 and European standard EN 13432 for industrial composting (based on PLA+PBAT film) and home and garden composting (based on PBS film). Our compostable coffee bags are produced from film materials that are certified compostable under the DINCERTCO Sign. You are welcome to contact our professional team with any questions regarding compostable coffee packages.