Back sealed sachet is the main part of food packaging in the market at present. Usually, high barrier materials are used, which have the functions of moisture-proof and light-proof. The bag is often filled with nitrogen, and the back sealed structure helps to maintain the nitrogen environment and delay oxidation. At the same time, the bulging bag can provide buffer space for potato chips, and reduce the extrusion breakage rate in the case of transportation and accidental drop.

In addition, the front of the back-sealed bag has no edge sealing, which can completely present the brand pattern and design, enhance the attractiveness of the shelf, and support surface treatment processes such as bright surface, strengthen product differentiation and increase product sales.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the packaging film materials in the market, which are listed below.

- Fossil chemical polymer films

- Aluminum foil metal sheet

- Vacuum metalized film materials

- Ceramic film substrates

- Plant-based biopolymer materials

- Biodegradable film materials

- Compostable substrate films

- Fully recyclable substrate films

We are committed to creating story-telling packaging, deeply establishing emotional connection with consumers, increasing brand appeal and memory, and establishing a good brand image.

In this paper, we will analyze the exact aluminum foil material of this 135g potato chips back sealing bag, which will help this food manufacturer to achieve greater success in the market.

Packaging Foil Materials

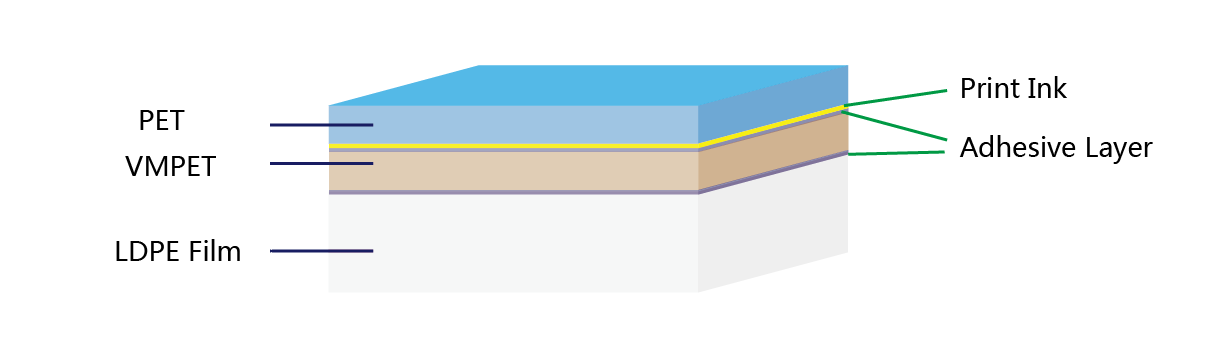

We adopted a better foil structure with excellent packaging performance. Usually we call it PET/VMPET/LDPE. As shown in the following figure.

It consists of three layers, the external PET film is used as the printing base film, the VMPET film is used as the intermediate support layer, and the LDPE film is used as the internal sealing layer. In the field of food packaging, their composite structures are often used to improve barrier performance, mechanical strength and sealing performance.

PET Film

PET film, sometimes BOPET film, is one of the most commonly used printing substrates in the field of flexible packaging. It has good printability, mechanical properties, processing stability, high temperature resistance, oil resistance, air tightness and environmental protection.

VMPET Film

VMPET film is the abbreviation of vacuum metallized polyester film, which consists of polyester film (PET) and vacuum aluminized layer.VMPET film has good barrier, shading, metallic luster, flexibility and environmental protection. It can prolong the shelf life of contents, facilitate compounding, printing and molding, and improve the visual effect of packaging. Compared with pure aluminum foil, VMPET is thinner, which can reduce the material consumption and cost.

LDPE Film

LDPE film is the abbreviation of low density polyethylene film, and it is the most commonly used internal sealing film for multi-layer flexible packaging in various applications. It has good softness and transparency. Low density polyethylene (LDPE) can be completely recovered.

Thickness

In the picture below, we can see that the overall thickness of this pouch is 0.200 mm, which means the thickness of this foil laminate should be 0.100mm (equals 100 microns).

- As an outer layer material, PET provides high strength, high transparency and excellent printing performance, and its thickness is usually 12-25 μm.

- As an intermediate barrier layer, VMPT only needs 3-12μm in thickness, which can provide excellent oxygen and water vapor barrier performance and enhance the gloss and decoration of packaging.

- As a heat sealing layer, LDPE usually has a thickness of 50-100μm, which provides good heat sealing, flexibility and puncture resistance.

By optimizing the thickness design, the PET/VMPET/LDPE structure can reduce the material consumption by 15-30%, while maintaining stable performance and minimizing the material consumption, which conforms to the trend of lightweight, high performance and sustainable development.

Wonderful Printing Effect

- The PET film has smooth surface, high transparency and gloss, bright colors and strong layering after printing.

- VMPET film can effectively improve the printing adhesion, and its metal texture combined with printed patterns can achieve high-grade visual effects and enhance the added value of products.

- LDPE film is soft and malleable, and can be recycled.

PET, VMPET and LDPE can give full play to their respective advantages through composite technology, and realize the perfect combination of high definition, high barrier, metallic texture and flexibility. In the future, with the development of environmental protection and intelligence, PET/VMPET/LDPE composites will play a greater role in the packaging field.

Mechanical Properties

We put the mechanical properties of this 135-gram potato chips back sealed sachet at the top of the factory’s manufacturing. Our quality control system has taken strict measures to ensure that every order can achieve the expected results.

- Good tensile strength and tear resistance.Please watch the video.

As an outer material, PET has excellent tensile strength and tear resistance, can effectively resist external stretching and puncture, protect internal items.

VMPET: Aluminization layer enhances the rigidity and tear resistance of the film, while improving the barrier performance of the material.

As an inner material, LDPE has good flexibility and malleability, which can buffer external impact and prevent packaging rupture.

- Good impact resistance and cushioning, please watch the following video.

LDPE: The flexibility of the inner layer of LDPE enables it to absorb impact energy and prevent the package from breaking due to collision during transportation or storage.

PET and VMPET: the rigid structure of the outer material provides additional support to prevent the package from being deformed when it is impacted.

To sum up, the good mechanical properties of PET/VMPET/LDPE composite structure not only help to protect potato chips from external extrusion or puncture during transportation and storage, but also reduce the risk of packaging damage, improve the tear resistance and wear resistance of materials, further protect the integrity of packaging, and prevent potato chips from getting wet or deteriorating due to packaging damage.

Barrier Performance

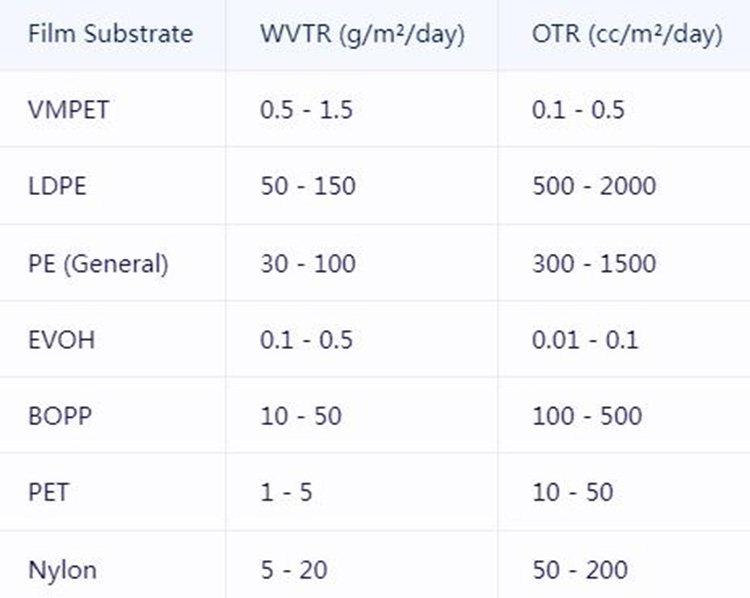

Barrier performance is the materials’ ability to prevent transmission of moisture or oxygen through the combined coating and substrate. These are quoted in cc/sq m/day for oxygen and g/sq m/day for moisture. Barrier performance started with improving the basic barrier of the polymer webs for the packaging industry to help extend the shelf-life of foods.

PET has a good barrier to water vapor, oxygen, odor, etc., and can effectively prevent the contents from oxidation, moisture or odor escape.

The aluminum plating layer of VMPET further enhances the barrier property to water vapor and oxygen, and the barrier effect is better than that of ordinary PET.

LDPE has good tolerance to most chemicals and protects the safety of contents.

To sum up, PET/VMPET/LDPE composite structure has excellent barrier performance advantages, which plays a multi-layer synergistic effect.

Gradient barrier: PET provides outer support and foundation barrier, VMPET enhances barrier performance, and LDPE is used as inner layer to realize heat sealing, forming a functionally gradient structure.

Complementary performance: the strength of PET is combined with the barrier property of VMPET, and the flexibility of LDPE makes up for the deficiency of the former two, and the overall performance is balanced.

With the continuous updating of packaging, some packaging with better barrier performance and appearance are more favored by customers.

- PET/AL/PE

- BOPP/VMCPP/PE

- PET/EVOH/LDPE

Technical Data Sheet of 135-gram potato chips back sealed sachet

Here, we attach the specification sheet of this 135g potato chips back sealed sachet , which is made of foil laminated matte PET/VMPET/LDPE.

More tests are included in this specification sheet, with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to know more about this kind of PET/VMPET/LDPE, you can read it here.

More Sustainable Materials Options

In recent years, with the increasing burden of fossil chemical polymer materials discarded into our environment, people pay more and more attention to more sustainable use of renewable materials. The demand for sustainable packaging is unprecedented, which leads to more environmentally friendly activities of enterprises. According to a recent survey of condiment market, more and more consumers are more likely to buy products that are conducive to environmental protection and sustainable use of recycled materials.

Compostable Packaging Materials

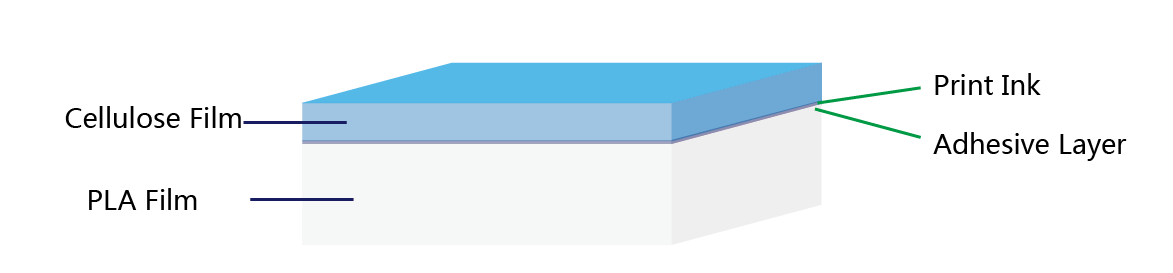

PT/PLA material usually refers to the composite structure of PT cellulose membrane and polylactic acid (PLA) membrane.

PLA film provides biodegradability (under the condition of industrial composting, it can be completely degraded into carbon dioxide and water within 6-12 months; The degradation cycle in the natural environment is 2-5 years), and the flexibility and plasticity ensure that the whole material can be recycled or composted.

The natural source of cellulose membrane (cellulose comes from renewable resources such as wood and agricultural waste, reducing carbon footprint) further enhances the environmental protection performance.

PT/PLA material is an ideal choice to replace traditional plastics by compounding cellulose and PLA, which realizes the balance of air permeability, mechanical strength and biodegradability. Its environmental protection performance is outstanding, but the cost and degradation conditions need to be solved.

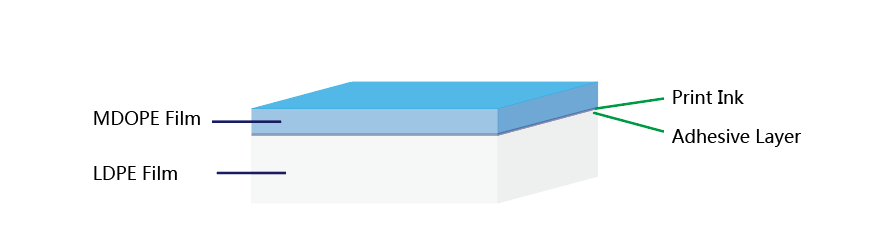

Fully Recyclable Mono Materials

Molecular structure of LDPE (Low Density Polyethylene): The long chain has a large number of branches with different lengths, the molecular chains are loosely arranged, and the crystallinity is low (55%-65%).

MDOPE (Modified Polyvinyl Alcohol or Metallocene Catalyzed Low Density Polyethylene) Molecular Structure: Through molecular modification or metallocene catalysis technology, more regular molecular chains are formed, with fewer branched chains and higher crystallinity.

Through the optimization of molecular structure, while maintaining the density close to that of LDPE, MDOPE has significantly improved its mechanical strength, tensile strength and puncture resistance, and at the same time improved its recycling rate. The single material system (MDOPE/LDPE) can be directly reprocessed through the existing recycling facilities without complicated separation. For example, the recovered MDOPE/LDPE film can be re-granulated and used to produce new packaging materials, thus reducing the pollution in microplastics.