Description

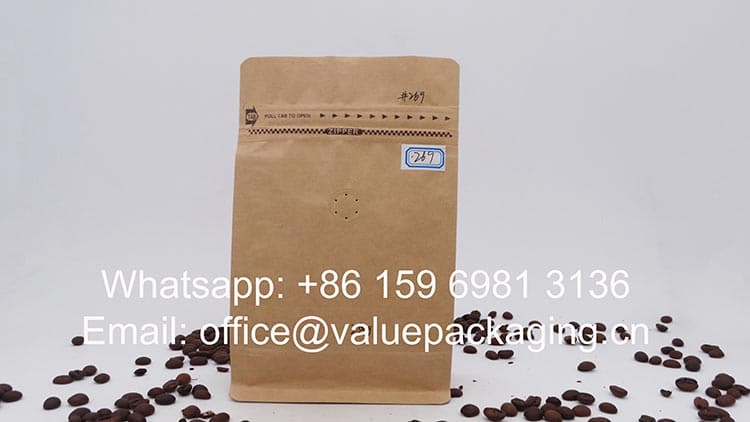

250g Coffee beans Kraft Paper Box Bottom Package

You are suggested to watch the video below for a further knowledge on this kraft paper box bottom package intended for 250g coffee beans.

Introduce

This glamorous flat bottom gusseted package is made of Kraftpaper70/VMPET12/LDPE60 foil material.This is a flat bottom gusseted package well prepare for coffee beans 250g, which is quite famous in the consumer market for coffee products. The main body is set in brown colors, which attracts so charming the coffee. We are supplying this package to our customer in a quantity of 3 million per month.

Here we are going give a more understanding on this tremendous package, and hope it helps you to choose your perfect packaging.

Foil Structure

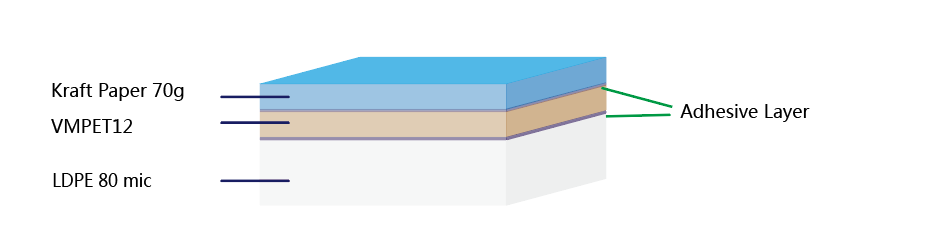

kraft-paper-70gsm-VMPET12-LDPE50-foil-structure

This foil materials is a reinforced structure with excellent properties for coffee beans. The foil structure is KraftPaper70/VMPET12/LDPE60, with graphic as below.

Kraftpaper70, has the characteristics of environmental protection, recycling, cost-saving, with the increasing environmental requirements of packaging in the international market, Kraft paper as a high strength, environmental protection, etc. It has become the preferred material for packaging. As a packaging material, kraft paper folding resistance, toughness are very strong, in the transport process can be high-strength compression. In the food industry packaging Kraft paper is also very popular, food-grade Kraft paper performance is very superior, with moisture-proof waterproof, oil immersion, low temperature freezing and other characteristics. Food grade kraft paper packaging costs much less than general packaging materials and food grade kraft paper can be recycled.

VMPET12,is a material which has a good metallic luster and good reflectivity, giving people a sense of luxury, it can be used to package goods improve the grade of goods. It has excellent gas barrier, moisture resistance, shading and fragrance, not only on Oxygen and steam has a strong barrier,it can block out almost all external interference such as ultraviolet and visible light. It can replace aluminum foil to a certain extent, but the amount of aluminum is greatly reduced, not only save energy and materials, relatively speaking, the cost of commodity packaging has reduced a lot.

LDPE 60, means low density polyethylene film, which is the most used inner sealing layer for the coffee beans pouch. It is able to provide enough sealing strength and airtight property for the final packages.

The final thickness for this foil laminate should be 120 microns, with tolerance +-5%. and the toughness of this foil will be enough to finalize good package profile for 250g coffee beans.

Flat Bottom Gusseted Package Properties

1 Great print quality

The artwork is achieved in gravure printing which can print up to maximum 10 colors. With advanced print techniques and print defects inspection system, we are now outputing fantastic print effect against the customers’ artwork.

Actually, this amazing artwork is reversely printed on the inner side of Kraftpaper70 film and then laminated to VMPET12 and LDPE60, which can keep the original colors of the customer artwork in dramatic effect.

250g kraft paper skinny box bottom coffee package

2 Barrier Performance

The barrier performance of Metallized film should be taken as a very good one during the flexible packaging substrate films. When Metallized film is trapped in this foil laminate, actually, the barrier performance is good enough to keep coffee beans product in a fine protection.

250g kraft paper skinny box bottom coffee package

3 High Mechanical Strength

This reinforced laminated foil is achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, upon customer requirements, and you may check the exact values of this foil material in the Technical Date Sheet part of this post.

tensile-strength-lab-test

In our daily QC work, there is an more easy and reliable method to check if the bag strength is enough to meet the various conditions in the operations of filling, transport, loading and unloading, distribution. We perform drop test against each order, of course, the standard for this drop test should be decided against customer needs.

Here, we are going to fill 1kg of coffee beas into this Metallized film package, and perform drops for 3 times, and check if there is any breakage for the package.

You are suggested to watch the video below.

You can judge from the video, the package stays well after 3 drops, really great physical strength.

Package Dimension and Filled Level of 250g Coffee Kraft Paper Package

We will conduct detailed testing of our products to facilitate customers to have a general understanding of our products. We will make samples, and on our product length, width, height, renderings, weight production size test report, to the customer intuitive precision product effect.

Coffee Bag 250g Flat Bottom W125xH195+Box Bottom40x2 mm Package Dimension Test

Coffee Beans 250g Gusseted Package Dieline

250g Coffee Beans W124XH195+Gusset60+Flat Bottom+Inner Zipper#v304

The artwork design template should be helpful when you plan to print your logo and eye-catching artwork on this coffee beans package, and you may just download it and send it to your design to fill the creative artwork. You are advised to feedback to us with Illustrator or PDF file with high quality (>= 300PPI)

Technical Data Sheet of 250g Kraft Paper Skinny Box Bottom Coffee Package

This is the technical data sheet with our laboratory tests on the finished foil for coffee beans, the values are reliable and ensure it running well on your machine.

TL269 Technical Date Sheet of Premium quality printed kraft paper package for 250g coffee beans package.

Some main items are listed as below.

- Dimension Tolerance

- Print Appearance

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Impact Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ablity (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

You are welcome to reach us if you have any questions regarding the test or you need further test against any items.

How to Fill Coffee Beans into Premade Flat Bottom Gusseted Package

This is a durable and high speed automatic filling machinery especially developed for coffee beans that can achieve the flat package from 2g to 2kg. Upon our experience, if the customer would like to get a durable machinery for their long-term business, this would be a fine choice.

dry-fruits-nuts-packing-machine-into-premade-zipper-doypack

Here is the below for the working of this amazing machinery.

About the manufacturer

Qingdao Tongli Packaging Products Co., Ltd is a professional and reliable flexible converter and package print service supplier located in Qingdao, China more than 10 years, with competitive engagement in household cleaning chemicals, coffee packages, spout doypack package, dry nuts packages, pet food packages and human food applications.

We are now working with our customers in a long-term partnership around the world. You may just rely on us if you would like to get sustainable and reliable supply for your expect packages.

Reviews

There are no reviews yet.