Description

340 grams roasted beans zipper bag

Watch the video for this 340grams (12oz) good livingood box bottom coffee package.

Introduce

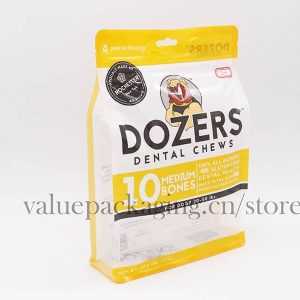

This wonderful 340grams coffee package is produced for livingood which presents its premise organic roasted coffee beans to the market, and this bag is well able to present outstanding quality packages for the products, and this bag is robust enough to works as great protection in filling, transport and distrubition process.

Here we are going to give a further analysis on this surprising coffee package, and hope you will get a great bag for your own products.

Foil Materials

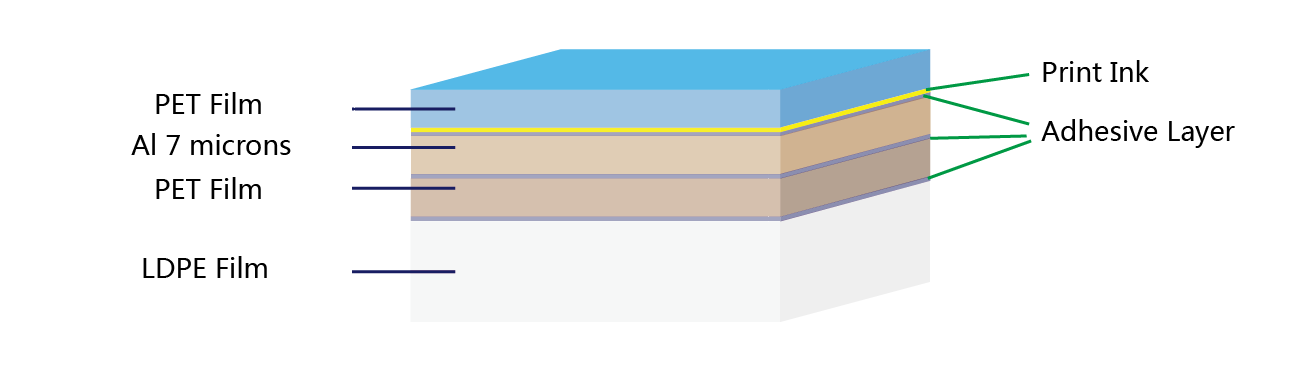

This foil materials is a strenghtened structure with great properties for coffee bag packages. The foil structure is PET12/AL7/PET12/LDPE80, with graphic as below.

PET-ink-adhesive-AL-PET-PE-foil-structure

PET12, is one of the most common used printing substrates in flexible packaging pouches. With great clarity, stable machanical strength and excellent printability, it is able to present the customer artwork print in great quality.

Al7, is short for aluminum foil metal sheet with thickness 7 microns, which is the most common used thickness in flexible packaging. It is of the best barrier performance among all the film materials, which can keep the orginal flavor and fragance for a prolonged time.

Second PET12, means a futher layer of polyester film 12 microns applied, which is a reinforced foi laminate. With an extra polyester film 12 microns (short as PET12) applied, which isable to provide enough strength and standing profile for the package.

LDPE, means low density polyethylene film, which is the most used inner sealing layer for the coffee bag. It is able to provide enough sealing strength and airtight property for the final packages.

12 oz coffee beans bag

The last minute thickness for this foil laminate should be 120 microns, with tolerance +-5%. and the resolve will be enough to work out good standing effect.

Coffee Bag Performance

1 Great print quality

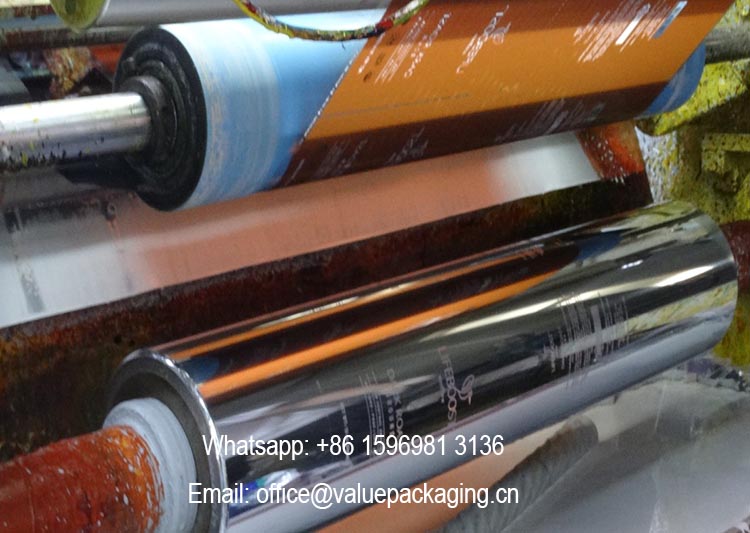

The artwork is achieved in gravure printing which can print up to maximum 10 colors. With advanced print techniques and print defects inspection system, we are now outputing zmazing print effect for the customers’ artwork.

340 grams roasted beans pouch

We provide a video below for you to better understand on the quality of this 12oz coffee package.

2 Skillful Matte Finish Effect

In some time,a layer of matte lacquer coating is applied over the outter layer of this foil laminate, small hidden lines may appear on the surface as of bad craftsmanship. Now, we are able to achieve the matte finish effect in amazing quality, here will be no hidden lines when the customer is filling operation in the factory.

340 grams coffee zipper bag

You can watch the following video.

3 Enjoyable Package Making

As shown below, we have a smooth zipper and exquisite details and workmanship.Many converters may not be able to output this smoothe zipper place.

340 grams coffee beans zipper bag

You are advised to watch the video below to have a further understanding on the smoothe zipper of this 340grams coffee package.

This good-looking side guesst coffee package can attract more consumers to buy this products and create a perfect image for the branded products.

4 Good Barrier Performance

As mentioned earlier, this kind of foil laminate is finally made of a thin aluminum sheet, which can well block oxygen and water vapor. Usually, with this high barrier coffee bag, baked beans can be properly protected for a year, and when used by consumers, they can maintain the original flavor of the product.

5 Absurd Standing Effect

The bottom of this 340g coffee package is much like a box when the roasted beans are filled, and that will make the package well standing effect on the goods shelf, excellent for branding and sale.

340 grams roasted beans pouch

6 Strong Mechanical Performance

This reinforced laminated foil is achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, upon customer requirements, and you may check the exact values of this foil material PET12/AL7/PET12/LDPE in the Technical Date Sheet part of this post.

We perform drop test against each order and carry out drop test according to customer requirements.We are performing a daily QC work to guarantee the performance, and among all of them, drop test should be considered as the most reliable way to check if the bag strength meets the requirements of final application.

Here, we are going to drop the filled coffee bag from 1.6m high, for 5 times.

You can watch the video below to learn more.

After 5 drops for each package, and none of them breaks, all are dandy.

nonbroken-12oz-coffee-bag-after-drop-test-5times

7 Valuable Tap Zipper

The tab zipper, which is also called rip zipper. It can easily tear the coffee bag from the label with a straight line effect.

340 grams coffee beans package

Here, we just perform the tear test on this 340grams flat-bottom livingood coffee bag, you may get a more understanding.

8 Easy to Fill coffee beans

As shown in the following picture, when the package is opened, the large opening can be very convenient.

340 grams roasted beans zipper pouch

With the side gusset and bottom gusset, the bottom for this coffee package is like a box (that’s why it is also called box pouch), that makes the fall of the roasted beans much more easily into the bag.

340 grams coffee beans zipper pouch

340 grams Coffee Bag Dimension and Filled Level

The filled effect is very important for the package.It is depending on the package dimension and the products filled. When 370g/1000ml of coffee is filled into the package, the filled level is about to take around 70% of the total height, which is normal operation in filling standup pouches. You may check the filled level in below picture.

340 grams roasted beans bag

Watch the video below to have a further understanding on the dimsion test and filled level.

Below dimension test report includes all the details, you can just forward to your customer for reference.

Coffee Bag-340g-Flat Bottom-W125xH230+Box Bottom40x2 mm -Package Dimension Test#483

Great Artwork Printing

A good creative artwork matters much more than most people expect, as most people tend to buy a product they feel good for.

340 grams coffee zipper pouch

For the printing produce in our plant, we are able to achieve the artwork in maximum 10 colors. With in-line print defect inspection system, more than 98% of the common print defects can be removed, you may have a further understanding by below video.

We will have to request a minimum order quantity of 10,000 bags against customer artwork. As to print each color, there will be a tank of printing inks offered to the rolling print cylinder. If we print only 5, 000 pcs, that will be huge waste of inks, film materials and labor.

print-cylinder-immersed-in-ink-tank

So if the customer is just looking for hundreds or thousands of coffee bag, he is advised to take from the stock items, like matte white coffee bag or matte black coffee bag, that should be much more cost-effective than custom printed bag.

Artwork Design Template

Here is the artwork design template for this 340grams flat bottom coffee package, and you may just download and forward this file to your designer for artwork design.

Design Template 12oz coffee beans W125XH230+Gusset80+Flat Bottom Pouch

Fine Air-release System

340 grams coffee beans pouch

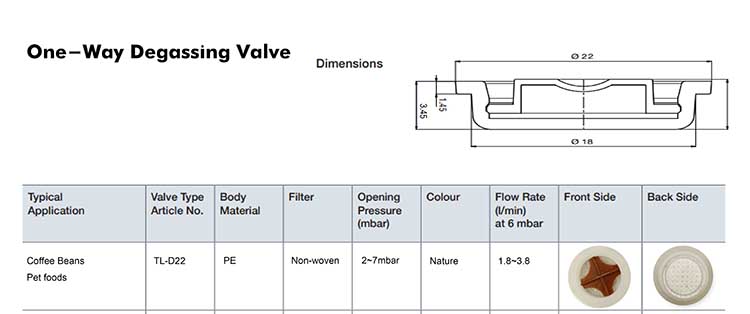

A degassing valve is applied neatly onto the coffee bag, which enables the air to be released from the inside package under pressure 2~7mbar.

TL-D22-degassing-valve

With the development of biodegradable materials, there is also compostable degassing valve available for compostable coffee packages.

Technical Data Sheet

Here, we are going to share with you the test in our plant against some essential items, with values listed in this technical data sheet.

How to fill this flat bottom coffee pouch

About the manufacturer

Qingdao Tongli Packaging has devoted itself to the manufacture of quality coffee bags for more than 10 years, with long-term customers around the world. You may just rely on us if you would like to get sustainable and reliable supply for your coffee packages.

Reviews

There are no reviews yet.