Description

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

Watch the video for this matte printed clear film foil roll for untiflatulent products 16ml 3 sides sealed sachet.

https://www.youtube.com/watch?v=T1nA1VVyMG8

Introduce

This lovely roll film is well intended for the premium quality sachets of untiflatulent products 16ml. It runs well on the vertical-form-fill-seal line and be converted into 3 sides sealed sachet.

Here we are going to give a further explaination on this amazing roll, and hope it helps you to decide your perfect package.

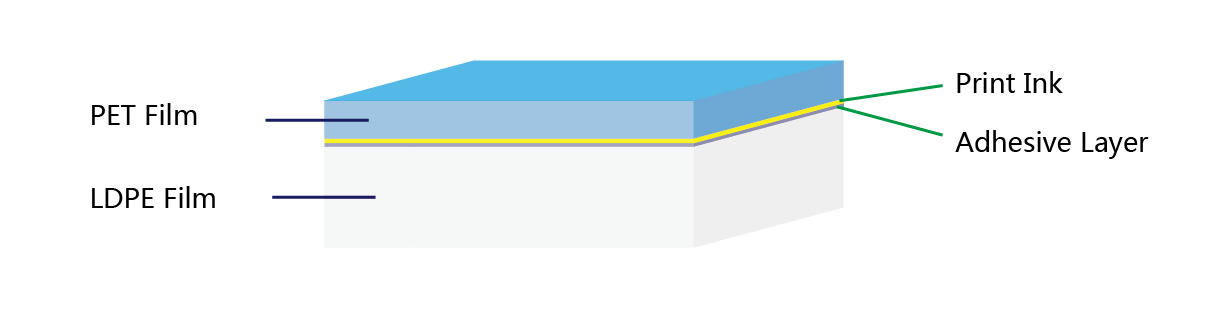

Foil Structure

This foil materials is a reinforced structure with excellent properties for coffee bag packages. The foil structure is PET12/LDPE, with graphic as below.

PET-ink-adhesive-LDPE-film

PET12, is one of the most common used printing substrates in flexible packaging pouches. With great clarity, stable machanical strength and excellent printability, it is able to present the customer artwork print in great quality.

LDPE, means low density polyethylene film, which is the most used inner sealing layer for the coffee bag. It is able to provide enough sealing strength and airtight property for the final packages.

The final thickness for this foil laminate should be 60 microns, with tolerance +-5%. and the toughness of this foil will be enough to finalize good package profile for 50 grams of ginger powder products.

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

Untiflatulent Rolls Properties

1 Great print quality

The artwork is achieved in gravure printing which can print up to maximum 10 colors. With advanced print techniques and print defects inspection system, we are now outputing fantastic print effect against the customers’ artwork.

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

2 Excellent Glossy Finish Effect

A layer of glossy lacquer coating is applied over the outter layer of this foil laminate, and in some cases, small hidden lines may appear on the surface as of bad craftsmanship. Now, we are able to achieve the giossy finish effect in amazing quality, without any hidden lines, without any enfluence on the filling operation at customer plant.

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

3 Enough Barrier Performance for Untiflatulent products

mocon-oxygen-water-vapor-permeation-rate-tester-min

With mocon O2/H2O/CO2 permeation tester equiped in our laboratory, we are able to keep a more close eye on the barrier performance of each laminate foil produced in our manfuacturing plant.

Below table shows the WVTR (short for water/moisture vapor transmission rate) and OTR (short for oxygen transmission rate) against foil laminate PET12/LDPE45

| Standard | Unit | Value | |

| WVTR | ASTM E 96 | g/m2/24hr | 9.84 |

| OTR | ASTM D 372-99 | cc/m2/24hr | 36.2 |

This foil materials proves to be working well for dry ginger powder proudcts distritubed around the country. And of course, if you are looking for a better package with higher barrier protection for your products, then we may like to get another reinforced metallized layer into the foil laminate.

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

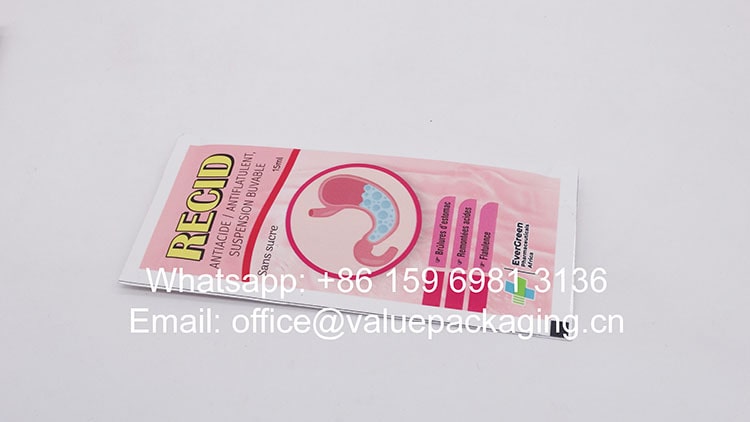

4 Great Final Package Profile

When the untiflatulent products is filled on the machine, the foil roll is going to be converted into excellent 3 sides sealed sachet, which brings eye-catching effect to the branded products.

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

5 High Mechanical Strength

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

This reinforced laminated foil is achieved with great mechanical strength, with some standard items as below.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, upon customer requirements, and you may check the exact values of this foil material in the Technical Date Sheet part of this post.

tensile-strength-lab-test

In our daily QC work, there is an more easy and reliable method to check if the coffee bag strength is enough to meet the various conditions in the operations of filling, transport, loading and unloading, distribution. We perform drop test against each order, of course, the standard for this drop test should be decided against customer needs.

Here, we are going to fill 1000grams of salt into this PET12/LDPE foil pouch package, and perform drops for 5 times, and check if there is any breakage for the pillow bag.

drop-test-1kg-salt-against-PET12-LDPE65-foil-thickness-80-microns-min

You are advised to watch the video below.

You can judge from the video, the package stays well after 5 drops, really great physical strength.

6 Easy Tear from the Sawteeth

sawteeth-on-sealed-sachet-enable-east-tear-min

Usually, sawteeth can be achieved during the cuting of the roll foil on the filling machinery, and it will enable the pillow pouch sachet to be torn easily against this PET12/LDPE foil.

Here, you can watch the video below for a further understanding.

Package Dimension and Filled Level

For the filling process, the filled effect matters much, of course, and that is depending on the package dimension and the products filled. Against 16 ml of untiflatulent products, we perform the filling test here, and below picture shows the filled line, excellent!

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

Watch the video below to have a further understanding on the dimension test and filled level.

Below dimension test report includes all the details, you can just forward to your customer for reference.

Untiflatulent Bag-16ml-3 Sides Seal Sachet-W60xH130 mm -Packaging Dimension Test#RTLR-009

Artwork Printing

A good creative artwork matters much more than most people expect, as most people tend to buy a product they feel good for.

R009-Printed-film-roll-for-untiflatulent-products-16ml-3-sides-sealed-sachet

For the printing produce in our plant, we are able to achieve the artwork in maximum 10 colors. With in-line print defect inspection system, more than 98% of the common print defects can be removed, you may have a further understanding by below video.

We will have to request a minimum order quantity of 300kgs per design against customer artwork. As to print each color, there will be a tank of printing inks offered to the rolling print cylinder.

one-cylinder-to-print-one-color

If the customer just start up their business, and he would like to initiat his business at the lowest cost, he may try clear unprinted film, and plan a logo printing when the business goes bigger.

16ml Untiflatulent Products 3 Sides Sealed Sachet Dieline

Here is the artwork design template for this 16ml untiflatulent products 3 sides sealed sachet, and you may just download and forward this file to your design for design.

untiflatulent-16ml-3-Sides-Sealed-W60XH130-5mm-edge-seal-Dieline-Artwork-Design-Template-R009

The artwork design template should be helpful when you plan to print your logo and eye-catching artwork on this coffee bag, and you may just download it and send it to your design to fill the creative artwork. You are advised to feedback to us with Illustrator or PDF file with high quality (>= 300PPI)

Technical Data Sheet of 50grams Ginger Powder Pillow Bag

Here, we are going to share with you the test in our plant against some essential items, with values listed in this technical data sheet.

Some main items are listed as below.

- Dimension Tolerance

- Print Appearance

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Impact Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ablity (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

You are welcome to reach us if you have any questions regarding the test or you need further test against any items.

More Sustainable Options

With increasing burden on the plastic pollution, more and more products are now seeking for packages which are more sustainable, like compostable packages, recyclable mono materials packages, plant-based materials packages. They all proves to be more eco-friendly than the traditional multilayer packages which are even very difficult to be recycled.

1) Home compostable film material packages

12oz-certificated-compostable-high-barrier-coffee-package

Thanks to the fast development of plant-based film materials, now we are able to present the multi-layer standup pouch and roll foils in full home compostable options.

The compostable substrate films are as below.

- BOPLA Film

- PLA+PBAT Film

- Kraft Paper

- Metallized Paper

- Cellulose Paper

- Metallized Cellulose Paper

- PBS Film

Based on the compostable substrate film, we are developing kinds of multi-functional packages for various applications, as below

- High barrier performance packages, for roasted coffee beans, nutritions, milk powder, snacks or biscuits.

- Alkaline resistant packages for hand wash, laundry cleaning chemicals etc

- Frozen packages, like fish, noodles, or soup products

- Vacuum packages for vegetables, rice, red beans etc

- Hot filling packages for juice

- Microwave packages

Along with the extentions of compostable film materials, more and more products are now starting to get well packed in home compostable packages, with some well-applied foil structures as below.

| Biodegradable Foil Laminate | WVTR (g/m2/24hr) | OTR (cc/m2/24hr) |

| BOPLA40/PLA+PBAT60 | 62.2 | 267 |

| Cellulose30/PLA+PBAT60 | 131.5 | 5.6 |

| Kraft Paper45g /PLA+PBAT60 | 44 | 742 |

| Kraft Paper45g/BOPLA40 | 41 | 380 |

| Metallized Paper69g/PLA+PBAT40 | 27 | 127 |

| Cellulose30/Metallized Cellulose20/PLA+PBAT60 | 23 | 0.16 |

| Cellulose30/Metallized Cellulose20/BOPLA40 | 25 | 0.12 |

| Metallized Paper 69g/Cellulose30/PLA+PBAT60 | 5.6 | 1.12 |

| Kraft45g/Metallized Cellulose20/PLA+PBAT60 | 26 | 0.22 |

| Cellulose30/Kraft45g/PLA+PBAT60 | 19 | 117.2 |

| Cellulose30/Metallized Paper69g/PLA+PBAT60 | 8.9 | 1.1 |

You may have a further understanding on the biodegradable home compostable materials and pouches here.

2) Mono Materials Recyclable Pouch Packages

804-matte-black-mono-materials-standup-doypack-with-zipper-coffee-bag-250g

Mono meterials pouch packages are truly recyclabled, as they can be easily processed into plastic granules which can be used again for other applications. However, for the traditional multilayer laminates, take PET/LDPE for example, it is difficult to be processed, as PET and LDPE are quite different material, and can not be melted under the same conditions. That’s why momo materials pouch packages are becoming so widely popular in the packaging field, and highly reputed in the consumer market.

At present, mono materials pouch are basically divided into Polyethylene channel and Polypropylene channel, with polyethylene channel much more popular, as they can be converted into kinds of standup pouch packages with relative high performance.

Here we list the film materials that can be well intended for mono-materials recyclable pouch packages.

- MDOPE Film

- BOPE Film

- APE Film

- LDPE Film

- LLDPE Film

- CPE Film

- ABOPP Film

- CPP Film

- VMCPP Film

- VMBOPP Film

Various foil laminates can be achieved based on above film materials with different properties, which is intended to meet the particular requirements for specific product. Some foil laminates are well-known as below.

- MDOPE/APE

- MDOPE/LDPE

- MDOPE/EVOH-LDPE

- MDOPE/HDPE/APE

- MDOPE/BOPE/APE

- BOPE/APE

Upon our experience, mono materials pouch can be well intended for honey products.

You may have a further understanding on the recyclable mono materials and pouches here.

How to fill black pepper powder into this pillow bag out of film rolls

TLEN1362 Durable high-speed automatic filling machinery for ginger powder 50g-1000g pillow pouch

This is a durable and high speed automatic filling machinery especially developed for black pepper powder products that can achieve the pillow pouch package from 50g to 1000g. Upon our experience, if the customer would like to get a durable machinery for their long-term business, this would be a fine choice.

Here is the below for the working of this amazing machinery.

About the manufacturer

Qingdao Tongli Packaging has been engaged in flexible converting industry for more than 10 years in Qingdao, china, with long-term customers around the world. You may just rely on us if you would like to get sustainable and reliable supply for your expect packages.

Reviews

There are no reviews yet.