Description

white-kraft-paper-bag-for-walnut-kernels

1 Introduction

This admirable walnut kernel bag presents its premium walnut kernels to the Chinese market. This package is well able to present exceptional quality packages for the products and works as great protection in the filling, transport, and distribution process.

Here we will give a further analysis of this amazing walnut kernels bag, and hope you will get a fantastic package for your products.

white-kraft-paper-bag-for-walnut-kernels

2 Foil Materials

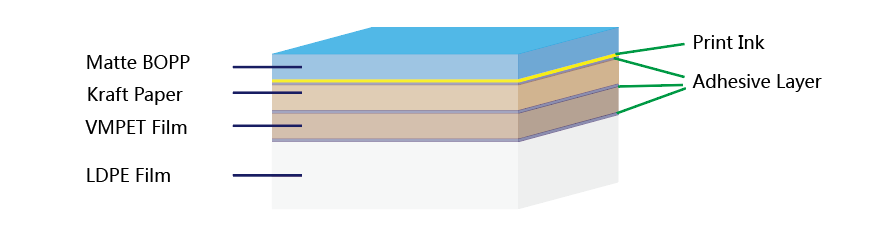

This foil material is a reinforced structure with excellent properties for walnut kernel packages. The foil structure is BOPP/Kraft Paper/VMPET/LDPE, with a graphic as below.

Let’s first get a further understanding of each substrate layer material.

Matte BOPP, or matte biaxially oriented polypropylene, is a polymer film with a matte finish that absorbs light instead of reflecting it. With a matte finish effect on the outside, Matte BOPP film is widely used to improve visual effects and add a fashionable touch to the packaging.

It’s made up of multiple layers, including a polypropylene core and tie layers, and is often co-extruded with a skin copolymer layer on one or both sides.

The film is prepared through extrusion and biaxial orientation and can be made using either the tubular or tenter frame process.

Kraft paper is one of the most commonly used materials to increase the eco-friendly and sustainability for the packages. Brown kraft paper is a heavy-duty, durable, and tear-resistant paper that is usually brown in color and made from wood pulp. It’s known for its natural wood fibers and textures and has an earthy, rugged look. Kraft paper is versatile and can be used for a variety of purposes.

VMPET film is short for vacuum metalized polyester film, which is achieved under vacuum conditions to deposit a thin layer of aluminum atoms onto the surface of PET (polyester) film substrate, and finally realize a bright metallic film that is widely used in flexible packaging and standup pouch packages.

LDPE means low-density polyethylene film, which is the most used inner sealing layer for coffee bags. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance. LDPE is recyclable and reusable, making it a popular alternative to traditional plastic. LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. Most importantly, LDPE membrane can be modified against the requirement of specific products, and finalize the package with great seal strength and protection. The thickness of the LDPE membrane will be decided against the particular application.

The final thickness for this foil laminate should be 170 microns, with a tolerance of +-5%. and the toughness will be enough to present a good standing effect for finished bags.

You may read here on our company website to get a deeper understanding of BOPP/Kraft Paper/VMPET/LDPE Foil Laminate and see how it can help you to decide the ideal packages.

3 Properties and Quality Assurance

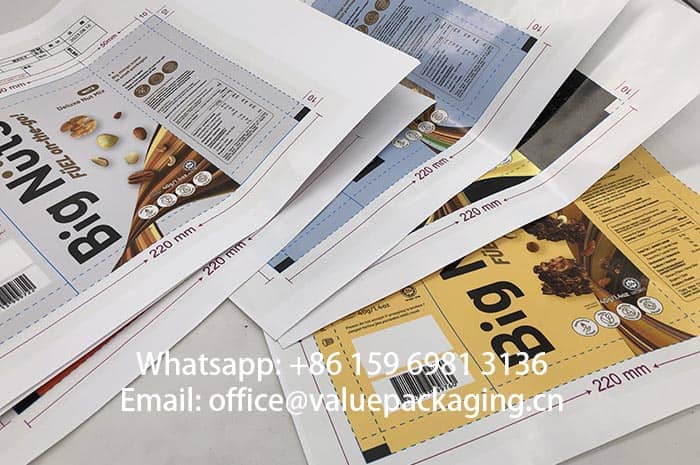

3.1 Exquisite print quality

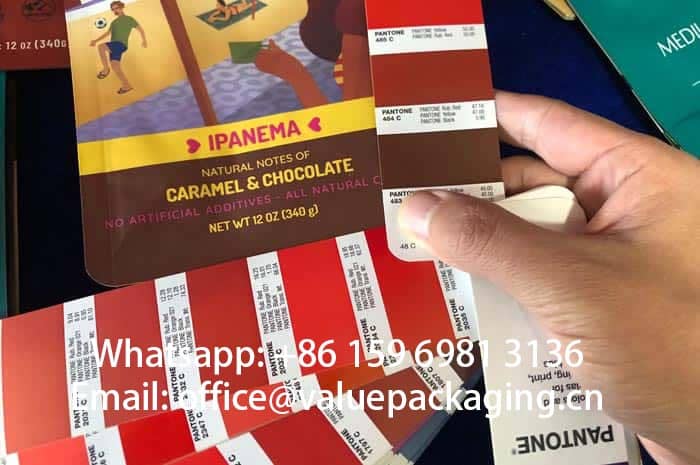

The artwork is achieved in gravure printing on our rotogravure print press which can print up to a maximum of 10 colors. With advanced print techniques and a print defects inspection system, we are now outputting fantastic print effects for the customers’ artwork.

white-kraft-paper-bag-for-walnut-kernels

In our manufacturing plant, we take serious measures to achieve high color fidelity and consistency for repeated printed orders, and here we are going to give a basic introduction.

a. Color Analyzer

This color analyzer is one of the auxiliary tools in our system to achieve the highest standard for color fidelity. The exact Advanced doesn’t just validate the color of CMYK and spot color inks, it can simultaneously measure four M modes to visualize the spectral reflectance of a substrate or ink, measure the concentration of a specific ink, and measure the difference of a substrate or ink over white and over black.

b. Pantone Color Code

The Pantone color guide would be very helpful in locating a specific color for the print service supplier and the customers, especially if there is a large area printed in a single Pantone color. For many Pantone colors, the accuracy may be influenced by the printer, paper substrate, and environmental factors when it is printed onto physical photo paper. We will locate the Pantone Color Code with the customers in their artwork design before the order is put into production.

c. Physical Printed On Photo Paper

Computer files such as JPG, PDF, PSD, AI, etc can not be taken as the guide to determine the color in print produce, as they present the colors through electronic screening devices. Different electronic screens may be set in different parameters by the various manufacturers, which will inevitably interfere with the color presentation. Artwork can only be a reliable guide when printed on a physical substrate, with the most common photo paper applied.

You may read here to understand more about how our company ensures color fidelity and consistency for all our orders.

Measure taken to achieve high color fidelity and consistency in reprints

3.2 Delicate Bag Making

The bag is achieved with delicate details, which can create a perfect impression for the consumers when they pass by the products, and cause them a purchase. Some customers do like to buy a product out of its gorgeous profile.

white-kraft-paper-bag-for-walnut-kernels

3.3 High Barrier Performance

As explained previously, this foil laminate is finalized with a four-layer structure, which is of great barrier performance against oxygen and moisture vapor. Usually, the roasted beans should be well protected to keep the original flavor and fragrance for a prolonged period, to enable the beans enjoyed by the end consumers.

3.4 Fantastic Standup Effect

The bottom of this walnut kernel kraft paper bag is much like a box when thewalnut kernels are filled, and that will make the package well stand up on the goods shelf, good for branding and sale.

white-kraft-paper-bag-for-walnut-kernels

3.5 Great Mechanical Strength

This reinforced laminated foil can greatly protect walnut kernels ranging from 100g to 5lb volume.

We perform various inspections and tests to check the mechanical strength of the finished pouch, like drop tests, hard sudden strikes, and anti-pressure tests.

- Tensile Strength

- Sealing Strength

- Anti-puncture Strength

- Burst Impact Strength

- Anti-pressure Property

The above tests are performed against each order, on customer requirements, and you may check the exact values of this foil material PET/Kraft Paper/VMPET/LDPE in the Technical Date Sheet part of this post.

3.6 Easy Filling of walnut kernels

A large opening can be achieved on the block bottom coffee bag, which enables the easy and fast filling ofwalnut kernels into the pouch.

white-kraft-paper-bag-for-walnut-kernels

4 Quality Control Measures

Laboratory-test-equipment

Serious quality control measures have been taken in our manufacturing plant, to ensure each order is finished meeting the requirements of particular customers. With more than ten years of working experience in this field, we finalize this QC manual standard, to make sure each order is produced following the correct procedure.

Here, please allow us to guide you further into our QC system.

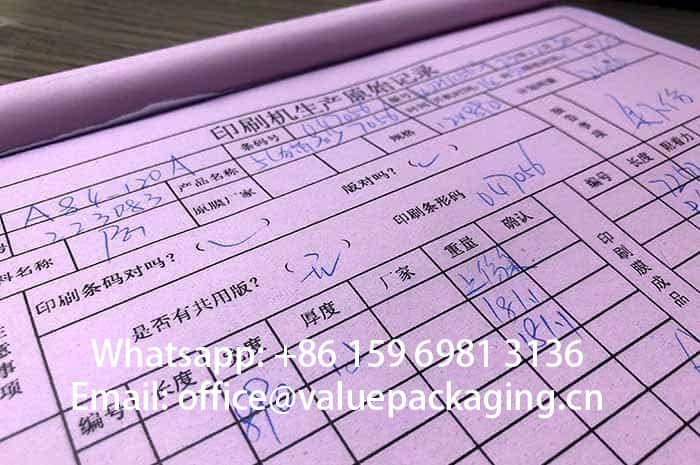

4.1 Manufacturing Traceback

We apply a strict recording system to document the manufacturing details, such as environmental conditions, craftsmanship parameters, production facility conditions, etc, which allows us to trace back whenever there is a problem.

4.2 QC Test Report Against Each Order

There will be a QC test report issued against each order produced, with the core items evaluated in it. It is highly appreciated by our customers.

You may read here to understand the QC test report for an order of 250g and 1000g coffee bags.

4.3 Print Inspection

Pantone-color-examine-purple

In our manufacturing plant, the print inspection is always taken and done in a serious way, as we will never allow the customer’s artwork to be achieved in a way that deteriorates their business. On our gravure print press, there is an in-line inspection system that can eliminate more than 98% of the defects in the printing process.

You may check how it works on our control panel.

There is also a supplementary off-line inspection equipment, to allow us to do the print inspection again whenever it seems necessary.

off-line-gravure-print-inspection-for-roll-foils

We are now producing bags against customer artwork, and we surely love to support the startup and market-testing period for our customers. We will accept a minimum order quantity of 10,000 bags printed against customer artwork design.

4.4 Airtight Property Test

The finished coffee bag should be completely airtight, to get the products well-protected from oxygen and moisture in the environment. We perform the airtight property test against each order with the device as below.

In actual operation, we will pick up 1 bag every 1,000 pcs, and perform the test following the procedure in our QC manual.

4.5 Drop Test

Drop test should be considered as a very reliable way to check if the bag strength is enough to meet the various conditions, as it copies the way when the products fall off the good shelves, and the finished bag will suffer great sudden shock. In our daily QC work, We perform a drop test against each order, of course, the standard for this drop test should be decided against customer needs.

Here, we are going to drop the filled coffee bag from 1.6m high, for 5 times.

You are advised to watch the video below, for a further understanding.

After 5 drops for each bag, none of them breaks, all are fine and dandy.

4.6 Anti-Pressure Test

Pressure-resistance test is another effective method to decide if the final package will serve as great protection for the products, especially liquid products, like household detergent liquids, and windshield washer fluids. For coffee bags, we will perform the anti-pressure test in our daily QC work, to ensure each order is finished with great mechanical strength.

The leakage or breakage of the coffee bag will surely be a disaster, either for the distributor or the manufacturer. We will never expect this thing happens in our customer’s business.

Sometimes, for easier and faster operation, we may just get one person to stand on the well-sealed and inflated bag, to check if there is any burst of them.

Bruce-standing-on-inflated-coffee-bag-package

4.7 Laboratory Tests

Labortory-test-equipment-tongli-packaging

Laboratory tests are essential to keep us updated with the intrinsic properties of the foil materials which are not visible to the human eyes. It is crucial to gain a thorough understanding of the data about the production of our bags. The craftsmanship can be improved bit by bit to pursue premium quality bags based on thorough analysis and application of these data. You may check more of these tests in the Technical Data Sheet part of this post.

4.8 Third-party Inspection

SGS-third-party-inspection

Third-party inspection is available for all our orders on agreed standards or regulations.

5 Human Food Safety

All the film materials, inks, adhesives, and solvents used to convert into kinds of food bags and packaging materials will comply with the regulations for human food safety. The below graphic shows the mass spectra in migration tests on these multilayer flexible pouches that are in direct contact with foods.

Through the below link, you will be able to study the certificates on each of the materials adapted in our factory.

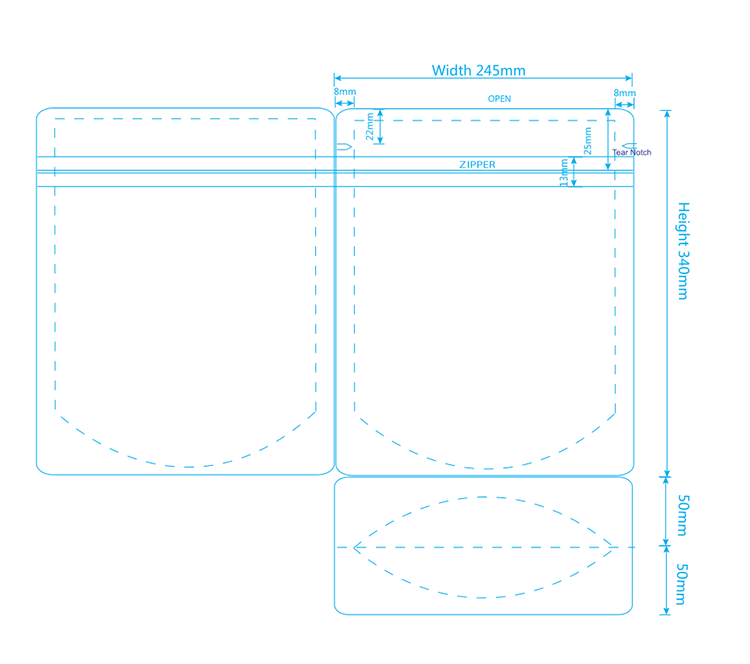

6 Dieline of 12oz box bottom coffee bag

white-kraft-paper-bag-for-walnut-kernels

The die-line of this 500g walnut kernel bag is essential when the customers want to achieve a fantastic artwork design for their package. All the details, like dimension, valve position, and zipper position are well stipulated in this die-cut line.

We attach the editable PDF file here, and the customer can just download and forward it to his designer for further creative work.

500g W245xH340+BG50 – Inner zipper

7 Technical Data Sheet of white kraft paper bag for walnut kernels

Laboratory-test-flexible-roll-foil

You may check the attached PDF file for further knowledge of the specifications of this 500g walnut bag.

TL-99 Technical Data Sheet of kraft paper flat paper bag for 500g walnut

Some main items are listed below.

- Dimension Tolerance

- Print Appearance

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

Just reach us if you have any questions about any of the items.

8 More Sustainable Options

With the increasing burden on plastic pollution, more and more manufacturers are now seeking more sustainable packages, like compostable film materials, recyclable mono materials packages, and plant-based materials packages. They all prove to be more eco-friendly and sustainable than the traditional plastic films which are usually derived from fossil chemicals, and very difficult to recycle and break down in the environment.

Here, we are going to share some of the trending sustainable packages for the walnut kernel market.

8.1 Compostable film material packages

Thanks to the fast development of plant-based film materials, we can present the multi-layer standup pouch and roll foils in full compostable and biodegradable options.

The compostable substrate films we adapt to convert the multi-layer flexible pouches are listed below.

- BOPLA Film

- PLA+PBAT Film

- Kraft Paper

- Metallized Paper

- Cellulose Film

- Metallized Cellulose Paper

- PBS Film

- PVDC Coated Cellulose Film

- Metalized BOPLA Membrane

We are now achieving multilayer compostable foil materials based on extrusion coating lamination, solvent-free lamination, and dry lamination, and then converting them into various types of flexible pouches against customers’ requirements.

Some of the common compostable foil structures are listed below.

- Kraft Paper/PLA+PBAT Membrane

- Kraft Paper/BOPLA Membrane

- Cellulose/PLA+PBAT Membrane

- Kraft Paper/PBS Foil Membrane

- Metallized Paper/PLA+PBAT Membrane

- BOPLA/PLA+PBAT Membrane

- Cellulose/Metallized Cellulose/PLA+PBAT Membrane

- Kraft Paper/Metallized Cellulose/PLA+PBAT Membrane

- Cellulose/Metallized Paper/PLA+PBAT Membrane

- Kraft Paper/Cellulose/PLA+PBAT Membrane

- Kraft Paper/Cellulose/PBS Membrane

- Metallized Paper/Cellulose/PLA+PBAT Membrane

Here, we are going to introduce the main performance of these compostable materials pouches.

a. Compostable

All the film materials we adopt are certificated compostable, under home or industrial conditions, complying with the standards EN 13432 or ASTM 6400.

The films will present different biodegradation behaviors under different conditions, such as industrial composting facilities, home and garden conditions, and natural soil conditions.

In most cases, industrial composting will be able to achieve faster biodegradation of the compostable film materials than other composting progress, as it is able to provide better conditions.

In most cases, industrial composting will be able to achieve faster biodegradation of the compostable film materials than other composting progress, as it is able to provide better conditions.

Some manufacturers would like to have better biodegradation behaviors of their own compostable packages under natural soil conditions, as in most cases, the abandoned package may not be recycled into human composting facilities.

You may read here to have a better understanding of the break-down progress of our compostable foil laminated materials under the natural conditions in Qingdao, Shandong, North China conditions.

The biodegrading process of compostable film materials buried in nature soil

b. Alkaline Resistant

We put a certain amount of bleaching powder into the compostable pouches with various foil structures, and placed them in an environment of 40~45 Celsius degrees, to accelerate the aging process of the compostable pouches.

The test result proves the compostable pouches will be fine for packing alkaline products, like household detergent powder, and hand wash cubes.

However, it is not ok for household liquid detergent and other liquid cleaning chemicals.

You may watch the video below for further knowledge on it.

c. Frozen Treatment

The compostable pouches can be well intended for frozen treatment for some food products, and the mechanical property of the frozen pouch still works well as good protection for the products during the transportation and distribution process.

You may watch the video below to study the test in our office.

d. Vacuum Packages

The compostable pouches can be intended for the vacuum packages for products, like milk powder, nutrition products, etc.

e. Hot Filling up to 100 Celsius Degree

The compostable pouch will be fine for the hot filling process, which may work well for juice products.

Watch the video below to learn our test.

f. Microwave Oven Treatment

The compostable doypack can be well intended for microwave oven treatment, such as melting the candle wax, etc.

Please note, that there should not be a metalized film layer in the compostable pouch when it is intended for this microwave treatment purpose.

You may read here for a better understanding on compostable plant-based film materials packaging.

9 About the manufacturer

bag-making-department

Qingdao Tongli Packaging has devoted itself to the manufacture of quality bags for more than 10 years, with long-term customers around the world. You may just rely on us if you would like to get a sustainable and reliable supply for your coffee packages.

Reviews

There are no reviews yet.