This is a standup pouch, The package has a sloping top design for easy liquid dumping. The standup spout pouch uses a folded gusset at the bottom. This gusset is used to hold additional products and also provides a better display effect when the pouches are placed on the shelves. It is necessary for the foil materials to be robust and long-lasting to ensure that the products are well-protected during filling, transportation, and distribution.

Through a flexible combination of different polymer film materials, the foil materials can offer outstanding barrier capabilities. They can safeguard the products from air, moisture, and light. Additionally, creative artwork designs can be printed on every side of the standup pouch. These designs include all the branding and sales-related information, making the final packaging more appealing to consumers.

As a well-known flexible converter located in Qingdao, China, we are making the best use of the packaging film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable substrate films

- Fully recyclable substrate films

We are dedicated to producing standup screw cap bags for 250 ml liquid pouches with story-telling designs. These bags can improve product sales and build a favorable brand image.

In this post, we will analyze the exact foil materials of this 250 ml liquid soap screw cap spout bag pouch, hoping it could serve as a reference for your products.

Alright, let’s delve into the details of this standup screw cap spout bag.

Packaging Foil Materials

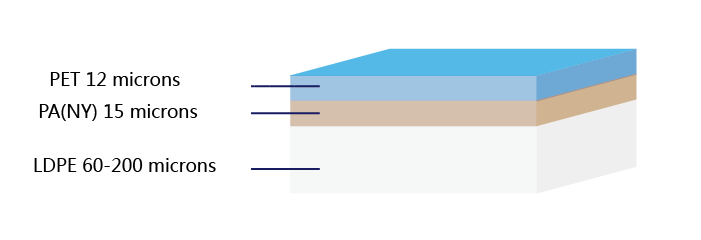

The figure below shows the composition structure of this laminated foil material used to convert this 250 ml liquid standup pouch.

The package for the material has three layers. The outside layer is 12 microns of PET material, the PA film is 15 microns working as the middle supportive layer, and finally, the LDPE film works as the inner sealing layer.LDPE as a heat sealing layer, can make the package better heat sealed.

Next, let’s get into a deeper understanding of each substrate film material.

PET Film

PET material in the field of packaging excellence. First of all, it has a high level of transparency, allowing consumers to clearly see the product inside the package and enhance their desire to buy. Secondly, good barrier performance can effectively block oxygen, water vapor, and odor, greatly extending the shelf life of the product. In addition, excellent mechanical properties, high strength, and crisp, protect the product in transportation and storage, while easy to display on the shelf. In addition, the weight is light and portable, reducing transportation costs and convenient for consumers to carry. Finally, the chemical stability is good, not easy to react with the product, coupled with easy processing and decoration, can meet a variety of packaging needs.

PA Film

PA material has significant advantages in the field of packaging. We also called it NY. It has extremely high strength and toughness, and can effectively resist external impact and puncture, providing good protection for the products in the package. The excellent wear resistance ensures that the packaging is not easily damaged during transportation and use. It has good barrier properties to gas and water vapor and helps to keep the freshness and quality of the product. PA material also has good chemical resistance and can adapt to the packaging needs of different products. In addition, it can be made into different shapes of packaging through a variety of processing methods, providing more possibilities for product design. PA material is a good choice for packaging due to its reliable performance. Based on these properties, this material is a good choice for 250 ml liquid bags.

LDPE Film

LDPE, or low-density polyethylene film, is commonly used as the inner sealing layer in screw cap spout bags. It is lightweight and simple to manufacture. It has good chemical resistance and can withstand impacts well. Being recyclable and reusable, LDPE is a favored substitute for traditional plastics. It is non-toxic doesn’t cause contamination, and has a high level of resistance to breaking. Crucially, the LDPE membrane can be adjusted according to the specific needs of products, ensuring strong sealing and protection for the final package. The thickness of the LDPE membrane is determined based on the particular application.

These 3 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. Usually, we describe the finished laminate as PET12/PA15/LDPE foil.

Thickness

As you can see from the below picture, the overall thickness of this spout pouch is 0.38 mm, which equals to190 microns for this laminated foil.

So, what is the performance of this foil structure when it is used for a 250 ml liquid soap screw cap spout bag pouch? Will it get damaged during transportation?

Great Standup Effect

Through the below video, you may learn the standing effect when a 250 ml liquid soap screw cap spout bag is filled into a spout bag based on this laminated foil PET/PA/LDPE.

As the outer layer, PET film provides initial stiffness and strength. PA is located in the middle layer provides additional mechanical strength, enhances the tensile and tear resistance of the package, and maintains the standing form of the bag even when pressed by external forces making the product’s standing effect more strong. LDPE film, as the inner layer, ensures the sealing property and flexibility of the packaging.

Mechanical Property

The spout package will protect the 250 ml liquid soap screw cap spout bag during filling, transit, and distribution. Under the emergency circumstances of unexpected shock in delivery or packages falling off the goods shelf, the spout package will never be allowed to break. Can you ever imagine the leaked liquid contaminating the cartons or the floor?

We put the mechanical property of this 250 ml liquid soap screw cap spout bag standup sachet as our top priority in our manufacturing plant. Serious measures are taken in our QC system, to assure each order is finalized with the expected result.

To put it simply, a drop test of a filled package is one of the most reliable ways to check if the package may burst under sudden sharp forces.

In the below video,o you can learn about the different materials for 250ml spout doypacks for liquid soaps.

Therefore, for small-capacity products, materials such as PET/PE can also be selected as the packaging layer of the product, but if you need to go through long-distance transportation, there are certain requirements for the packaging strength, and the role of the PA film middle layer is very important

Barrier Performance

Usually, the barrier performance of a multi-material laminate is evaluated by WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate). The below table shows the typical values of the WVTR and OTR of the most common substrate films in flexible packaging.

According to our experience, all bags and pouches used for liquids should be light-shielded to protect the formula from working as intended. Because the bright light will affect the product in the bag to destroy its chemical composition, thereby shortening the shelf life. Therefore, the liquid suction nozzle bag should perform well in the shading performance.

In the above picture, We’re testing for puncture resistance, It can ensure that the product is not easily damaged during transportation and plays a good protective role

Furthermore, WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) are evaluated for this laminated foil, with typical values listed in the below table.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 6 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 8.5 |

Technical Data Sheet of 2500ml fabric softner liquids pouch

Here, we attach the specification sheet of this 2500ml fabric softner bag based on foil laminate PET12/PA15/LDPE180.

More tests are included in this specification sheet with items available listed as below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to get a further understanding of this PET/PA/LDPE laminated foil, you may just read it here.

More Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages which leads to a more eco-friendly activity of the business. Upon the recent investigation of the detergent market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Compostable Packaging Materials

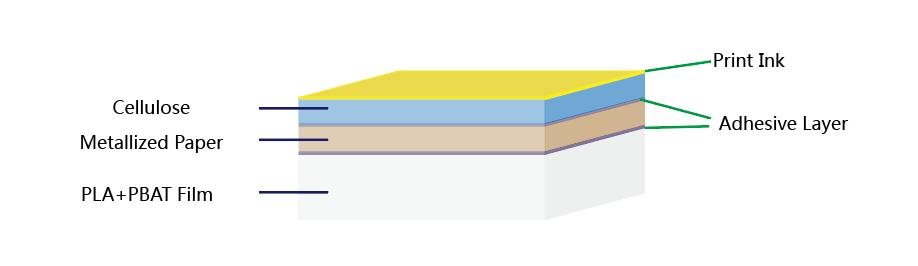

The below graphic shows clearly the foil structure for this laminated compostable foil.

The artwork is printed on the inner side of the plant-based cellulose film in reverse. A metalized cellulose layer serves as the light-shielding barrier, and the PLA + PBAT biodegradable film is the inner sealing layer. But it didn’t meet the customer’s expectations.

As mentioned before, the laminated foil must protect the liquid detergent formulas in the sachet. For this compostable foil, the liquid detergent ingredients can easily seep into the PLA + PBAT film that’s constantly in contact with the liquid. When a significant amount of ingredients passes through, it damages the adhesive between the PLA + PBAT and metalized cellulose, causing the foil to delaminate. So, for this customer, the compostable foil doesn’t fulfill the requirements.

In this case, compostable foil materials can’t be used for large-volume products like 1 liter, 2 liters, or 3 liters, which is unlike traditional polymer film materials. Contact us if you need more ideas.

Fully Recyclable Mono Materials

Some of our customers are actually moving to fully recyclable mono material bags which are well resistant to the formulas of liquid detergent.

Now it’s the end. You are welcome to reach us if you have any questions regarding 250 ml liquid soap screw cap spout bag pouch. Have a nice day.