Standup spout pouch is a popular package for yogurt products in the market. The self-standing spout bag utilizes a folding gusset at the bottom to hold excess products. A good standing effect can better display yogurt products to attract customers. So, It would require the foil materials to be strong and durable, to ensure the products are well protected during the filling, transit, and distribution process.

After a flexible combination of various polymer film materials, a certain function will be achieved on the finished foil laminate. It can effectively block air and light, prevent internal substances from deteriorating and leaking, and provide a guarantee for product quality. In addition, creative art designs can be printed on all sides of the stand-up pouch, covering all brand and sales information, making the final packaging more attractive in front of consumers.

As a reputable manufacturer of flexible packaging in Qingdao, China, we are making the best use of the packaging film materials in the market, listed below.

- fossil chemical polymer films

- Aluminum foil metal sheet

- vacuum metalized film materials

- Ceramic film substrates

- plant-based biopolymer materials

- biodegradable film materials

- compostable film materials

- mono film materials

We are devoted to creating story-telling standup yogurt screw cap bags that increase product sales and establish a good brand image.

In this post, we will analyze the exact foil materials of this 80 grams yoghourt screw cap bag pouch, hoping it could serve as a reference for your products.

Ok. Let’s learn about the packaging material information of this yogurt.

Packaging Foil Materials

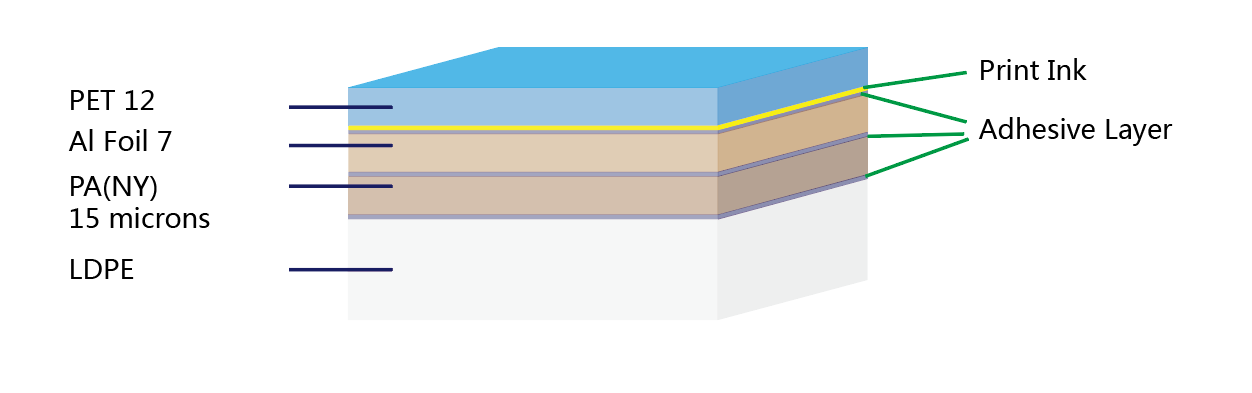

The figure below shows the composition structure of the laminated foil material used in this vertical yogurt spout bag.

The 80 grams yogurt screw cap bag pouch is made of 4 layers, as below

- PET 12 microns , works as the outside print substrate

- AL, short for aluminum foil, works as the very best barrier layer

- PA, short for polyamide, works as the reinforced layer

- LDPE film, works as the inner sealing layer

Next, let’s get a deeper understanding of each substrate film material.

PET Film

PET Film, is one of the most commonly used printing substrates in flexible packaging sachets. With great optical clarity, high gloss, good chemical resistance, stable mechanical strength, excellent dimensional stability, and great printability, it can present the customer artwork print in great quality, and also provide great mechanical strength to the final package.

The most commonly used thickness of PET film applied in the flexible packaging industry is 12 microns, which equals 0.48 gauge. So whenever you see PET12 or 0.48 g PET, you will know they mean the same thing.

AL Film

Aluminum foil is a thin, pliable sheet of aluminum alloy that finds wide applications for food packaging and wrapping.

Aluminum foil is 98.5% aluminum, with the remaining percentage primarily made of iron and silicon to increase strength and puncture resistance. It has many properties, including durability, non-toxicity, oil-proofness, chemical resistance, and excellent thermal conductivity.

Aluminum foil is widely used in flexible packaging because of its gorgeous barrier performance and light-shielding properties.

PA Film

BOPA stands for Biaxially Oriented Polyamide film, which is also known as biaxially oriented nylon (short as NY) film. BOPA film is outstanding in its high tensile strength, excellent anti-puncture ability, and barrier properties, which can resist impact and punctures in numerous applications.

LDPE Film

LDPE film is short for low-density polyethylene film, which is the most commonly used inner sealing film for multi-layer flexible packaging in various applications.LDPE, or low-density polyethylene, is a thermoplastic polymer that is a member of the polyethylene family of plastics. It is known for its flexibility, toughness, transparency, and corrosion resistance. LDPE is also lightweight, easy to fabricate, and has good chemical and impact resistance.

LDPE is nontoxic, non-contaminating, and has a high degree of break resistance. It’s also lightweight, corrosion resistant, and has good chemical and impact resistance. LDPE is often used in packaging materials, such as milk pouches and food wrappers because it’s a good moisture barrier and keeps products fresh. It’s also used in orthotics and prosthetics. LDPE is environmentally friendly, low-cost, and low-energy. However, it’s not suited for applications that require stiffness, high-temperature resistance, or structural strength. LDPE also has limited resistance to some chemicals, such as aliphatic and aromatic hydrocarbons, mineral oils, and oxidizing agents.

In our factory, these 4 layers are bonded together into a finished laminated foil material under the dry lamination or solvent-free lamination process. Usually, we describe the finished laminate as PET12/Al7/PA15/LDPE foil.

Thickness

As you can see from the below picture, the overall thickness of this spout pouch is 0.277mm, which equals138.5microns for this laminated foil.

So, how does this structure perform when used in yogurt spout packages? Will it break during transportation?

Great Standup Effect

This 4-layer foil structure is able to present exquisite stiffness and can be converted into this standing spout bag with excellent standup effect. In reality, this foil laminate is too stiff for 80 grams of yogurt to expand the doyack during the filling process. You may get a good understanding of the final effect of this spout bag through the video below.

Mechanical Property

The spout packaging will protect the yogurt product during filling, shipping, and distribution. Nozzle packaging should never be allowed to break in an unexpected shock during delivery or in an emergency when the package falling off the shelf. Can you imagine leaked yogurt staining cartons or floors?

In our manufacturing facility, we prioritize the mechanical performance of this 80 g stand-up yogurt bag. Our quality control system takes strict measures to ensure every order is completed with the expected results. In short, drop testing is one of the most reliable ways to check whether the package will break under sudden sharp force.

You may watch the video to understand the test process, with 3 drops for each bag, from height 1.6 meters. Actually, no one breaks.

Barrier Performance

Yogurt is very sensitive to oxygen, which may cause it to lose its freshness and flavor in a short time. Usually, yogurt should be sufficiently sterilized before being filled into this spout bag. Aluminum foil should be considered as the best barrier film layer among all the substrate films, and when this 4-layer foil structure is achieved, the finished foil can provide excellent barrier performance against oxygen and moisture in a durable way.

Here, we list the typical value of WVTR (short for water vapor transmission rate) and OTR (Oxygen Transmission Rate) of this PET12/Al7/PA15/LDPE multi-layer foil in the table below.

| Item | Standard | Unit | Typical Value |

| Water Vapor Transimission Rate | ASTM E 96 | g/m2/24hr | 0.01 |

| Oxygen Transmission Rate | ASTM D 372-99 | cc/m2/24hr | 0.01 |

Upon our experience, this foil structure is considered the most reliable laminate for yogurt products. Some inferior foil structures are also found applications for aluminum foil spout pouch for yoghurt products, as below.

- PET/AL/LDPE: the risk of broken packages will increase, and it should not be used for packages with volumes larger than 200ml.

- PET/AL/PET/LDPE: The anti-puncture ability of this foil is worse than PET/AL/PA/LDPE, which may also increase the leakage rate during the filling and distribution process.

We will make more explanations in future posts.

Technical Data Sheet of 80 gr yoghourt screw cap bag pouch

Here, we attach the specification sheet of this 80gr yoghourt sachet, more tests are included in this specification sheet with items available listed below.

- Yield (grams per square meter)

- Tensile Strength (Mpa)

- Elongation Rate (%)

- Coefficient of friction, short as COF

- Solvents Left (mg/m2 )

- Sealing Strength (N/15mm)

- Sealing Conditions

- Bond Strength (N/15mm)

- Burst Strength (J)

- Anti-Puncture ability (N)

- Drop Test Ability (cm)

- Anti-pressure ability (kgs)

- Water Vapor Transmission Rate (g/m2/24hr)

- Oxygen Transmission Rate (cc/m2/24hr)

If you want to get a further understanding of this PET12/Al7/PA15/LDPE laminated foil, you may just read it here.

More Sustainable Materials Options

Along with the increasing burden of fossil-chemical polymer materials discarded into our environment, there is an unprecedented demand for sustainable packages which leads to a more eco-friendly activity of the business. Upon the recent investigation of the detergent market, more and more consumers are more likely to purchase a product that acts toward environmental sustainability.

Compostable Packaging Materials

At present, there is only compostable zipper and degassing valve available for these compostable standup pouches. Compostable spout is now not available for yogurt product, based on our tests. It is still under research, and we will keep you posted when there is any progress on this project.

Fully Recyclable Mono Materials

Fully recyclable spout pouches are now flooding the market for light-weight products with volumes less than 250 grams or 250 ml. Upon our test, it can be well intended for yogurt.

Ok, thank you for reading to the end. If you have any questions about yogurt packaging, please contact us.