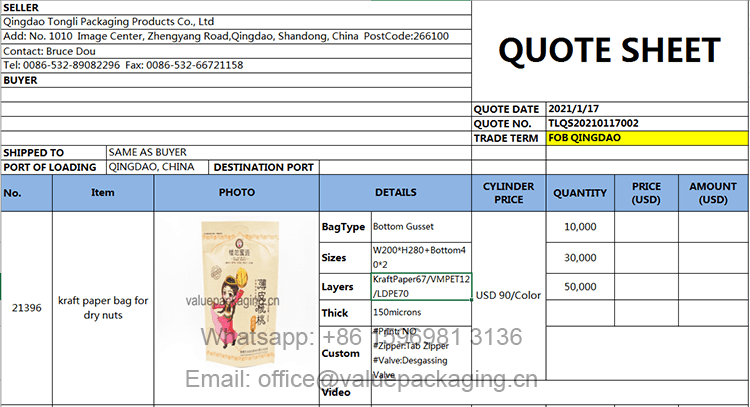

When the customers look for barrier packages for their products, like dry nuts, foods, coffee beans ,etc, usually the supplier is making quote as below.

Some customers may be confused by the VMPET12 stipulated in the quote sheet, and wonder if this is the correct package they should choose. and in this post, we are going to make a further explain.

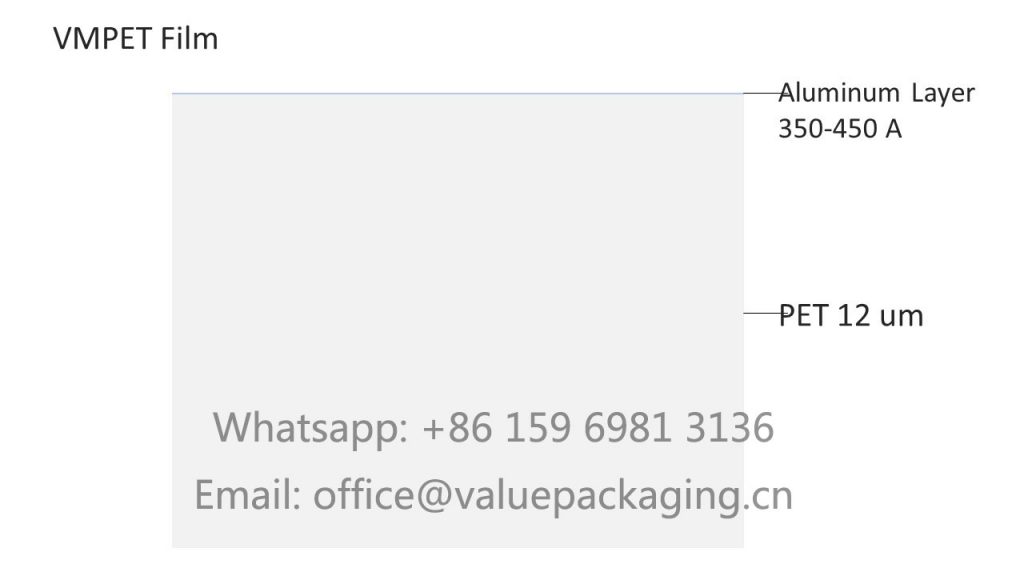

VMPET is short for Vacuum Metallized PET film, and in some places, people may just use MPET, that is short for metallized PET film, and they mean the same thing.

VMPET12

Clear PET film 12 microns, is the most common used thickness of PET film in flexible packaging. If the thickness increases, it may be too tough for flexible packages, if we go to lower thickness, the toughness may not be enough, and further more, the cost will increase. PET12 is just the shot for base film with the lowest cost ini flexible packaging.

As you can observe from the below picture, the thickness of aluminum atom layer on the PET 12 microns film can be neglectable, so when it is aluminum metallized, we usually take the thickness of PET film as the thickness of VMPET film.

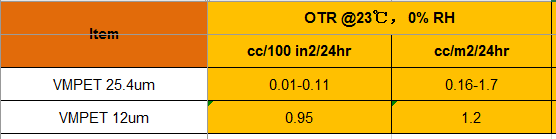

Barrier Performance of VMPET12 Film

When it comes to barrier performance, the WVTR (short for water vapor transmission rate) and OTR (oxygen transmission rate) are the most evaluated data, as moisture and oxygen are the top 2 factors that cause the products to deteriorate. As you can observe the data sheet below with WVTR and OTR value listed, you can see, VMPET12 film is really providing very good barrier performance.

Of course, in acutal applications, the package will not only prevent the moisture and oxygen to come into the package, and also prevent the inside products to penetrate into outside. and VMPET12 film may be not an ideal barrier foil when it comes to products with alcohol, acid sauce, oil, alkaline ingredients, which will damage the aluminum layer, and then further cause the barrier proprty to drop dramatically.

Read more here on the barrier property of VMPET film 12 microns

Foil Structures

VMPET film 12 microns will have to be entrapped between the foil structures to realize its barrier property and package purpose. With different requirements for the final products, usually the foil structures with VMPET film is listed as below

We will surely introduce more applicatons on VMPET12 film, and asisst with the customers for the best package for their products, of course, at the best cost. Reach us at office@valuepackaging.cn if you have any other questions.