The molecular in the plastic film is not laid in a linear way, some randomly laid, some cross-linked, especially when the film is produced by blown film craftsmanship, the moleculars in the film may be still a mess in some extent. Biaxial orientation is able to make the molecular layout in a more well-aligned way, however that is not enough to make the film able to be linear torn.

So when the plastic film materials are laminated, and when you try to tear the foil laminate from the tear notch, in most cases, you will come to below situation.

In this post, we are going to share with you 3 common methods we adapt to acheive a linear tear premade pouch.

Tab zipper

Tab zipper is the most common way when you would like to realize linear tear on your zipper pouch. The consumers can just grab he tab on this side, and pull, the chine of the tab zipper would naturally tear the pouch in an linear way. You may watch the video below for actual understanding.

Laser Score Tear

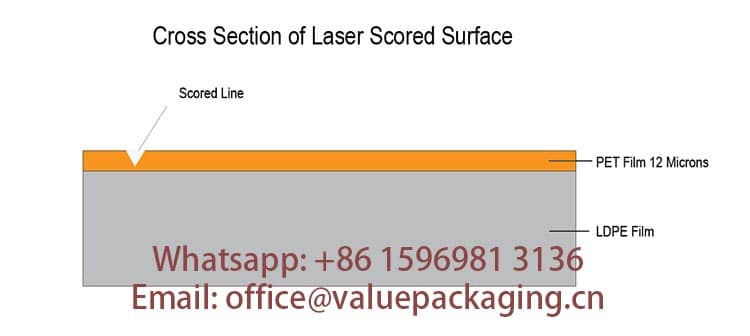

Laser score tear is to get the surface of the outside layer of the pouch foil laminate damaged in a certain extent, so when the tear strength is applied, the tear would go along with this straight score line, other than random rupture.

The laser score damage on the film surface is shown as below graphic.

and this is the layout for a laser scored zipper pouch, you can see the laser scored is above the zipper.

With this laser score treatment, this dry nuts zipper pouch can be torn in a linear way, you may watch the video for an actual experience.

Note, please reach us at office@valuepackaging.cn if you would like to get some sample for your own test.

Linear Tear Film Material

Another solution to achieve linear tear is to modify structure and arrangement for the moleculars in the film substrate, and here are some linear tear film material applied in flexible packaging industry.

- Linear tear LDPE film (with COC added in the poly resin)

- Liear tear PET film

- Linear tear BOPA film

So when these film are laminated and formed into pouch, it can be enabled with good linear tear property. And of course, there will need a tear notch at the tear place, so you can get a better understanding by the video below.

Ok, here I have listed all these 3 methods we adpat for our customers linear tear packages, and of course, you are welcom to reach us if you have any questions.